We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-19 Origin: Site

Cooling towers are essential in industrial and commercial applications to remove heat from water-cooled systems. Among different cooling tower designs, those made with FRP Material (Fiber Reinforced Plastic) have become increasingly popular due to their durability, corrosion resistance, and performance advantages. This article explains what an FRP cooling tower is, the main types available, how they work, and why choosing a reliable manufacturer like MACH Cooling (https://www.machcooling.com/) matters.

An FRP cooling tower is a heat rejection system constructed primarily with Fiber Reinforced Plastic (FRP) components. Unlike traditional cooling towers that may use wood, steel, or concrete, FRP cooling towers benefit from superior strength-to-weight characteristics and excellent resistance against corrosion.

FRP cooling towers are suitable for diverse environments—from power plants and factories to HVAC systems in commercial buildings—and remain one of the most reliable choices for long-term performance.

A round cooling tower features a cylindrical structure where air and water flow patterns are designed for efficient heat exchange. Round towers are widely used due to their uniform airflow and lower footprint in certain applications.

In contrast, the square cooling tower has a rectangular footprint. This design makes it ideal for modular arrangements or when installation space is limited. Square towers are common in commercial HVAC systems and industrial facilities with specific layout requirements.

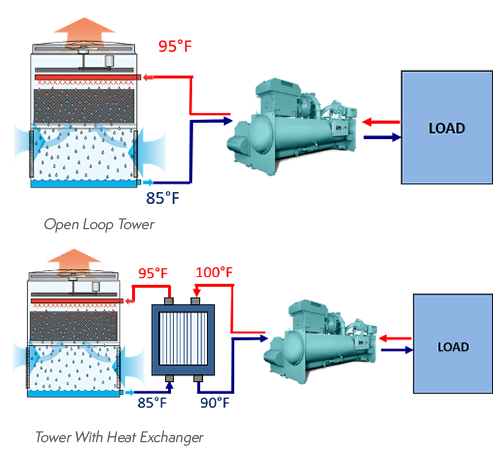

A closed cooling tower isolates the process fluid from the open-air environment. Water or other fluids circulate through a heat exchanger coil while external water provides cooling. This design is especially useful when process fluid contamination must be avoided.

The airflow pattern in a cooling tower has a major impact on performance and system efficiency.

In a counter flow cooling tower, air moves vertically upward while water flows downward. This opposing flow pattern maximizes heat transfer efficiency and is common in many industrial applications.

A cross flow cooling tower routes air horizontally through the fill media while water descends vertically. This design allows for easier access to internal components and simpler maintenance.

FRP Material offers significant advantages over traditional materials:

| Feature | Benefit |

|---|---|

| Corrosion Resistance | Ideal for humid and chemical-laden environments |

| Lightweight | Reduces structural support requirements |

| High Strength | Maintains integrity under load and thermal cycling |

| Long Service Life | Less maintenance and longer replacement cycles |

| Thermal Performance | Supports efficient heat transfer |

Compared with wood or galvanized steel, FRP towers resist rot, rust, and long-term degradation, making them a preferred choice for industrial, commercial, and process cooling applications.

FRP cooling towers reject heat through a combination of evaporation and convection. Warm water from the system enters the tower and is distributed over fill media. Air is drawn through the media, causing a portion of the water to evaporate and removing heat. The cooled water collects in the basin and returns to the system.

The two main components of the cooling mechanism are:

Heat Exchange Fill – Increases the contact area between air and water

Airflow System – Uses fans and natural draft strategies to move air through the tower

Efficient designs minimize water usage, optimize return temperature, and support consistent system performance.

FRP cooling towers are designed to maximize cooling per unit of water, reducing overall water usage and operating costs.

The corrosion-resistant nature of FRP prevents degradation from moisture, chemicals, and weather, making these towers ideal for long-term performance.

Modern FRP cooling towers can integrate advanced sensors for monitoring performance, water level, and airflow, supporting efficient and automated operation.

When choosing an FRP cooling tower, working with a reputable manufacturer makes all the difference. MACH Cooling (https://www.machcooling.com/) specializes in custom-engineered cooling tower solutions, including:

Round cooling tower models optimized for airflow and footprint

Square cooling tower designs for modular installations

Closed cooling tower systems for sensitive process fluids

Counter flow cooling tower and cross flow cooling tower configurations

Customized FRP solutions built to exact project specifications

| Advantage | Impact |

|---|---|

| Engineering Excellence | Optimal design for real-world conditions |

| FRP Expertise | Durable, corrosion-resistant systems |

| Global Service Support | On-time delivery and local technical guidance |

| Performance Validation | Reliable performance, low maintenance |

Partnering with MACH Cooling ensures that your FRP cooling tower installation meets project goals for efficiency, reliability, and lifecycle cost.

An FRP cooling tower delivers excellent performance, durability, and environmental resilience due to its advanced FRP Material construction. Whether you choose a round cooling tower, square cooling tower, closed cooling tower, counter flow cooling tower, or cross flow cooling tower, FRP provides a long-lasting solution that supports efficient heat rejection and lower maintenance.

By selecting a trusted manufacturer like MACH Cooling, you gain access to engineered solutions designed to meet your cooling demands with reliability and high return on investment.

Cooling Tower Inspection Services: Ensuring Efficiency And Safety

Cooling Tower Lightning Protection: Essential Safety Measures

How To Choose The Right Cooling Tower Float Switch for Your System

Cooling Tower Factory Insights: Production, Quality, And Innovation

Types of Cooling Tower Casing Materials: FRP Vs Metal Vs PVC

Top 10 Best Cooling Tower Companies in India (2026 Updated List)

Sustainable Cooling Towers: Balancing Evaporation And Water Use