We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-13 Origin: Site

A cooling tower is a vital component of many industrial and commercial facilities. Neglecting inspections can lead to inefficiency, safety hazards, and costly downtime. That’s where cooling tower inspection services come in. From identifying mechanical wear to spotting corrosion and leaks, these inspections keep your system running smoothly. This article will cover everything you need to know about inspections, including best practices, benefits, and insights from Mach Cooling.

Cooling towers handle massive volumes of water, constantly exposed to heat, chemicals, and environmental elements. Over time, components can degrade, leading to reduced efficiency, equipment failures, or safety incidents. Professional inspection services catch issues early, ensuring your system remains reliable and compliant with industry standards.

Inspections help maintain optimal water flow, heat transfer, and mechanical operation. They ensure that pumps, fans, and fill media are working as designed, which directly impacts energy efficiency and cooling performance.

From structural weaknesses to electrical issues, inspections identify potential hazards before they escalate. This proactive approach prevents accidents and protects both personnel and equipment.

Inspectors check for:

Corrosion on metal supports

Cracks in concrete or FRP structures

Loose or missing fasteners

Structural integrity is crucial; a compromised tower can lead to collapse or unsafe conditions.

Water nozzles and distribution basins must operate correctly to ensure uniform water flow. Inspections reveal blockages, uneven spray patterns, and scaling buildup.

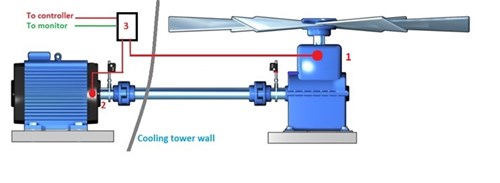

Mechanical systems are often the most stressed. Inspections include:

Bearing wear

Motor alignment

Fan blade condition

Vibration levels

Electric components are checked for:

Proper insulation

Connection integrity

Control panel functionality

This reduces the risk of electrical failures or fire hazards.

Inspecting fill media ensures efficient heat transfer, while drift eliminators prevent water loss. Blockages, damage, or microbial growth can severely reduce cooling efficiency.

A straightforward but essential method where inspectors look for visible signs of wear, corrosion, leaks, or misalignment.

NDT methods like ultrasonic testing, dye penetrants, and magnetic particle inspections detect hidden structural defects without disassembling equipment.

Thermal imaging identifies hotspots or areas of inefficient heat transfer.

Vibration analysis detects misalignment or bearing issues before they cause failures.

Routine checks monitor water levels, visual leaks, pump operation, and chemical dosing. These are quick inspections that prevent small issues from becoming major problems.

A detailed annual inspection covers all components, including structural integrity, electrical systems, and mechanical efficiency. This is the best time for thorough cleaning, repairs, and upgrades.

Catching problems early avoids unexpected shutdowns, reducing lost production time and repair costs.

Properly maintained cooling towers use less energy. Fans and pumps operate efficiently, while scaling and fouling are minimized.

Regular inspections prevent accelerated wear and corrosion, prolonging the life of your cooling tower components.

Look for certified professionals with experience in industrial and commercial cooling towers. ISO or CTI certifications indicate adherence to high standards.

Advanced diagnostic tools like thermal cameras, ultrasonic testers, and vibration sensors improve inspection accuracy.

Detailed inspection reports with photographs, data, and recommended actions make it easier to plan maintenance and justify upgrades.

A good provider offers guidance for repairs, replacements, and maintenance scheduling.

Mach Cooling (https://www.machcooling.com/) provides comprehensive inspection services:

Experienced certified technicians

Advanced NDT, thermal imaging, and vibration analysis

Detailed reporting and maintenance recommendations

On-site support for repairs and preventive actions

Clients report improved efficiency, reduced downtime, and extended equipment lifespan after using Mach Cooling services.

IoT sensors allow continuous water level and temperature monitoring. Digital dashboards alert operators to anomalies instantly.

Machine learning can analyze data trends to predict failures before they happen, making inspections smarter and maintenance proactive rather than reactive.

Regular cooling tower inspection services are essential to ensure efficiency, safety, and long-term performance. By combining visual checks, technical testing, and modern IoT monitoring, facilities can minimize downtime, reduce costs, and extend the life of their equipment. Partnering with trusted providers like Mach Cooling ensures your cooling towers operate safely, efficiently, and reliably for years to come.

Cooling Tower Inspection Services: Ensuring Efficiency And Safety

Cooling Tower Lightning Protection: Essential Safety Measures

How To Choose The Right Cooling Tower Float Switch for Your System

Cooling Tower Factory Insights: Production, Quality, And Innovation

Types of Cooling Tower Casing Materials: FRP Vs Metal Vs PVC

Top 10 Best Cooling Tower Companies in India (2026 Updated List)

Sustainable Cooling Towers: Balancing Evaporation And Water Use