We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-13 Origin: Site

Choosing the right cooling tower float switch might seem like a small detail, but it’s a critical decision that affects the efficiency, safety, and longevity of your entire cooling system. If you’ve ever experienced sudden water overflow, pump failure, or inconsistent cooling performance, you know how essential accurate water level detection is. This guide will help you navigate the types, features, and best practices for selecting the perfect float switch, with insights from Mach Cooling.

Water is the lifeblood of a cooling tower. Maintaining the correct water level ensures proper heat exchange, prevents pump damage, and reduces energy waste. A float switch acts like the guardian of this vital water level, sending signals to your pumps and control systems to maintain balance.

A float switch is a simple yet highly effective device that monitors the water level in your cooling tower basin. When water reaches a certain point, the float rises or falls, triggering an electrical signal. This can:

Start or stop pumps

Activate alarms

Control valves to maintain optimal water levels

Inaccurate water level measurement can lead to:

Pump dry-run damage – a pump running without water can fail quickly

Overflow and water loss – leading to wasted resources and potential facility damage

Inefficient cooling – water level impacts heat transfer efficiency

Mechanical float switches use a buoyant float attached to a mechanical lever or arm. They’re:

Simple and reliable

Cost-effective

Suitable for most standard applications

Electronic or magnetic float switches detect water level using sensors without mechanical movement. Benefits include:

High sensitivity and precision

Minimal wear and tear

Ideal for corrosive or challenging water conditions

Vertical switches move up and down with water level, common in basins with depth constraints

Horizontal switches pivot with the water, useful in wider or shallow basins

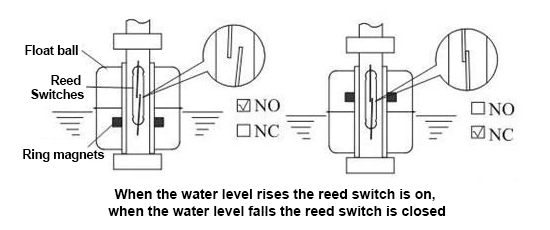

Normally Open (NO) – circuit closes when water reaches a certain level

Normally Closed (NC) – circuit opens when water reaches a certain level

Choosing the right type depends on your control system’s logic.

Cooling tower water can be harsh. Choose materials resistant to:

Chlorine and biocides

pH fluctuations

Hard water scaling

FRP, stainless steel, or coated floats are common choices.

Your float switch must handle the electrical load of the devices it controls, such as pumps or alarms. Always check:

Maximum switching voltage

Maximum switching current

Contact type suitability for AC or DC loads

Consider the operating environment:

Some switches are rated for high-temperature water

Others can withstand high-pressure conditions in closed-loop systems

Before selecting a float switch, ensure it matches:

Basin dimensions

Pump configuration

Control panel wiring and logic

Correct placement is crucial:

Float should move freely without obstruction

Avoid corners or debris-prone areas

Maintain recommended water depth for activation

Use proper gauge wire for load and distance

Ensure waterproof connections for long-term reliability

Follow manufacturer wiring diagrams

Disconnect power before installation

Use personal protective equipment (PPE)

Double-check mechanical and electrical connections

Remove debris or sediment from the basin

Check float movement and pivot points

Clean electrical contacts if needed

Float stuck due to debris → clean and reposition

Incorrect activation → check wiring and contacts

Corrosion damage → replace affected components

Investing in a high-quality float switch ensures:

Longer lifespan and reduced replacement frequency

Accurate water level monitoring

Reduced risk of downtime and maintenance costs

Safer operation of your cooling system

Some modern float switches can integrate with IoT sensors, allowing:

Remote water level monitoring

Alerts via apps or cloud dashboards

Predictive maintenance notifications

Float switches can work with PLCs or SCADA systems

Automates pump control, water top-up, and alarms

Enhances energy efficiency and operational safety

Mach Cooling (https://www.machcooling.com/) offers comprehensive float switch solutions for cooling towers:

Durable FRP and stainless steel float switches

Mechanical and electronic options

Fully compatible with automated control systems

On-site guidance and after-sales support

Clients benefit from reliable water level control and reduced maintenance issues.

Selecting the right cooling tower float switch isn’t just a technical choice—it’s an investment in the reliability, efficiency, and safety of your entire cooling system. Consider factors like type, material, load capacity, and compatibility, and pair them with smart innovations like IoT monitoring for maximum benefit.

Partnering with trusted manufacturers like Mach Cooling ensures you get high-quality, durable float switches that deliver precise water level control and long-term peace of mind.

Cooling Tower Inspection Services: Ensuring Efficiency And Safety

Cooling Tower Lightning Protection: Essential Safety Measures

How To Choose The Right Cooling Tower Float Switch for Your System

Cooling Tower Factory Insights: Production, Quality, And Innovation

Types of Cooling Tower Casing Materials: FRP Vs Metal Vs PVC

Top 10 Best Cooling Tower Companies in India (2026 Updated List)

Sustainable Cooling Towers: Balancing Evaporation And Water Use