We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-13 Origin: Site

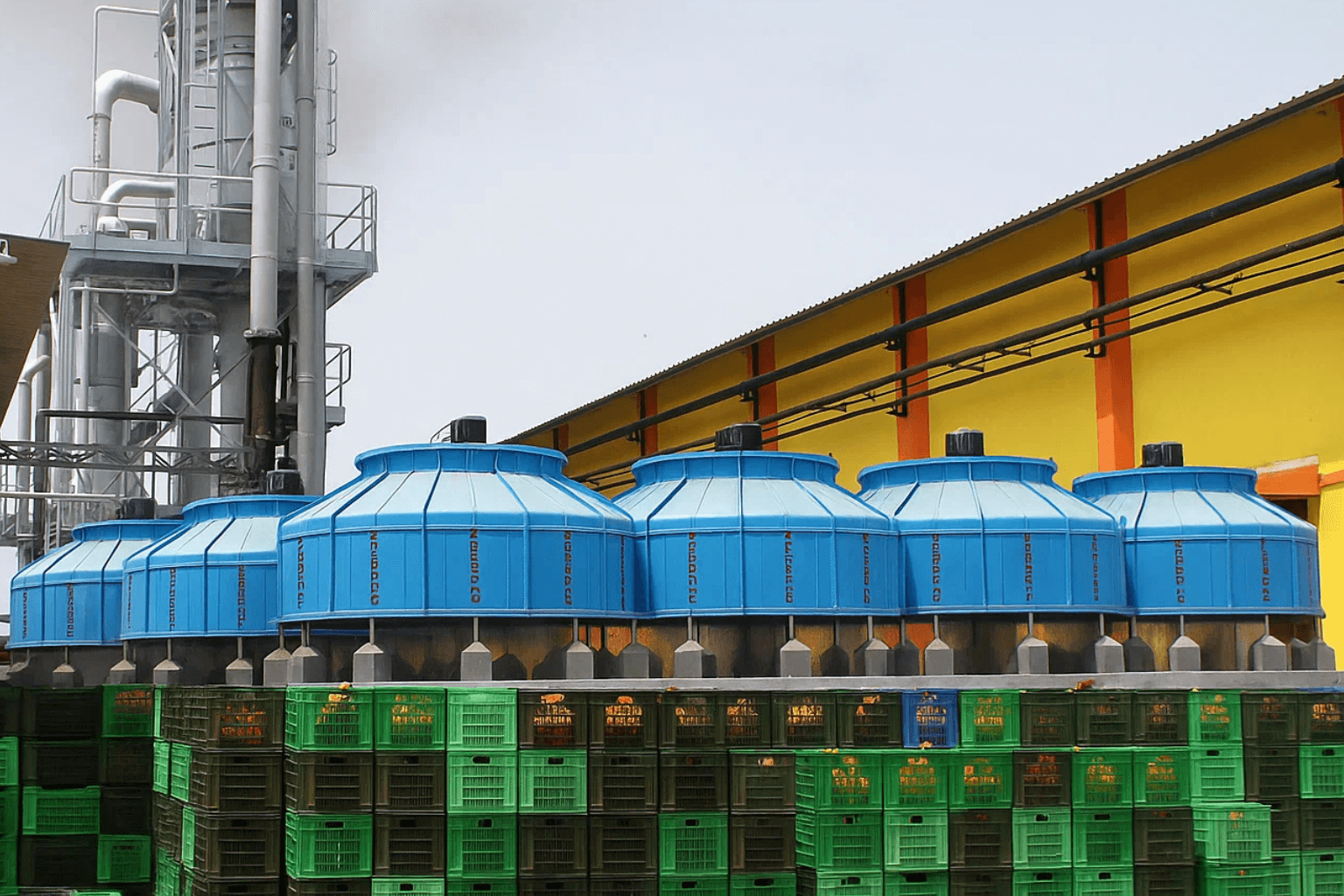

In the world of industrial cooling, the cooling tower factory is where innovation, precision, and quality converge. Whether you’re a plant engineer, procurement manager, or a consultant, understanding what happens behind the factory doors can make all the difference when selecting a reliable supplier. In this guide, we’ll take a deep dive into the production, quality control, and innovative practices of modern cooling tower factories, with real insights from Mach Cooling.

Cooling tower factories are specialized facilities where raw materials are transformed into high-performance cooling towers for industrial and commercial use. They handle everything from component fabrication to final assembly, ensuring that each unit meets performance, safety, and environmental standards.

Why does it matter which factory you choose? Imagine ordering a custom car and receiving one without quality checks—chaos, right? The right factory guarantees:

Reliable performance and longevity

Compliance with local and international standards

Efficient project timelines and minimized risk

Support for customization and special requirements

In short, a high-quality factory translates to peace of mind for your entire cooling system.

Modern cooling tower factories use structured production processes to ensure consistency, efficiency, and quality. Let’s break it down.

Materials define the performance and lifespan of a cooling tower. Common choices include:

FRP (Fiberglass Reinforced Plastic) – corrosion-resistant and lightweight

Galvanized or Stainless Steel – ideal for structural strength

Wood – often used in specialized applications

Choosing the right material depends on environmental conditions, chemical exposure, and budget.

FRP production involves:

Mold preparation – ensuring precise dimensions

Lamination – layers of resin and fiberglass applied

Curing – controlled temperature and humidity

Finishing – smooth surfaces and structural reinforcement

FRP towers are highly durable and require less maintenance over time.

Metal towers are fabricated using:

Sheet metal cutting and forming

Welding and bolting assemblies

Corrosion protection coatings

Load and stress testing

Metal cooling towers are favored for high-load industrial applications due to their structural robustness.

Wooden towers still have a niche in some regions. Their production includes:

Kiln drying and treating timber

Precision assembly of frames and fill

Protective coatings to resist moisture and pests

Structural testing before shipping

Top factories implement rigorous QC procedures:

Dimensional inspections for all components

Thermal performance tests on prototype towers

Load and vibration testing for structural integrity

Water flow and pressure verification

These checks prevent defects and ensure consistent performance.

Compliance with international standards boosts credibility:

ISO 9001 for quality management

CTI performance verification for thermal efficiency

CE marking for European markets

Certifications assure buyers that the factory adheres to global quality benchmarks.

Modern cooling tower factories use CNC machines, laser cutters, automated resin sprayers, and robotic assembly arms to improve accuracy and speed while reducing human error.

Automation includes:

PLC-controlled assembly lines

Automated quality inspection cameras

Digital tracking of production and inventory

Smart manufacturing enables factories to scale production without sacrificing quality.

Factories now optimize water use for cleaning and production and integrate energy-saving motors and VFDs to minimize electricity consumption.

Recycling scrap metal, FRP offcuts, and treating chemical waste responsibly reduces the environmental footprint of production.

Factories like Mach Cooling provide modular cooling towers tailored for unique layouts, enabling faster installation and easier maintenance.

Innovative factories experiment with new composite materials and coatings to improve corrosion resistance, thermal efficiency, and lifespan.

Reliable factories maintain sufficient stock, flexible schedules, and optimized logistics to meet client timelines without delays.

Top manufacturers offer on-site supervision, assembly guidance, and troubleshooting support to ensure smooth project execution.

Mach Cooling (https://www.machcooling.com/) exemplifies modern factory excellence:

ISO-certified production processes

High-efficiency FRP and metal towers

Integrated automation for quality and speed

Full technical and after-sales support

Clients benefit from reliable performance and global compliance with every project.

Integration of IoT for real-time monitoring

AI-driven predictive maintenance

Smart energy management systems

Eco-friendly materials and water-saving production techniques

Factories are evolving into smarter, greener, and faster production hubs.

A cooling tower factory is much more than a production site; it’s a hub of innovation, precision, and quality control. Understanding how factories operate—from materials and production processes to quality assurance and automation—can help you select the right partner for your industrial or commercial projects.

Manufacturers like Mach Cooling combine world-class production, certified quality, and forward-looking innovation to deliver cooling towers that meet the most demanding global standards. Choosing the right factory isn’t just about buying a product—it’s about investing in performance, reliability, and long-term peace of mind.

Cooling Tower Inspection Services: Ensuring Efficiency And Safety

Cooling Tower Lightning Protection: Essential Safety Measures

How To Choose The Right Cooling Tower Float Switch for Your System

Cooling Tower Factory Insights: Production, Quality, And Innovation

Types of Cooling Tower Casing Materials: FRP Vs Metal Vs PVC

Top 10 Best Cooling Tower Companies in India (2026 Updated List)

Sustainable Cooling Towers: Balancing Evaporation And Water Use