We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-12 Origin: Site

Cooling towers are the unsung heroes of industrial and commercial cooling systems. But have you ever thought about what keeps these giants running efficiently behind the scenes? That’s where auxiliary cooling tower equipment comes in. From pumps to sensors, from valves to control panels, auxiliary equipment ensures that the tower operates safely, efficiently, and reliably. In this article, we’ll explore everything you need to know about auxiliary cooling tower equipment, with insights straight from trusted manufacturers like Mach Cooling.

Auxiliary equipment in cooling towers refers to all the supporting systems that help the main cooling unit function optimally. Unlike the visible parts like fans, fill media, and casings, auxiliary equipment works quietly in the background but is critical for:

Circulating water efficiently

Maintaining water quality

Controlling flow rates and temperatures

Monitoring performance and safety

Without it, even the best-designed cooling tower can underperform or face premature failures.

Why is auxiliary equipment so crucial? Imagine trying to drive a car without a fuel pump or dashboard indicators. That’s what a cooling tower is like without its auxiliary systems. These systems:

Ensure steady water circulation and heat transfer

Prevent scaling, corrosion, and biological growth

Provide real-time monitoring for operational safety

Reduce energy consumption and maintenance costs

Effectively, auxiliary equipment is the backbone that keeps cooling towers reliable.

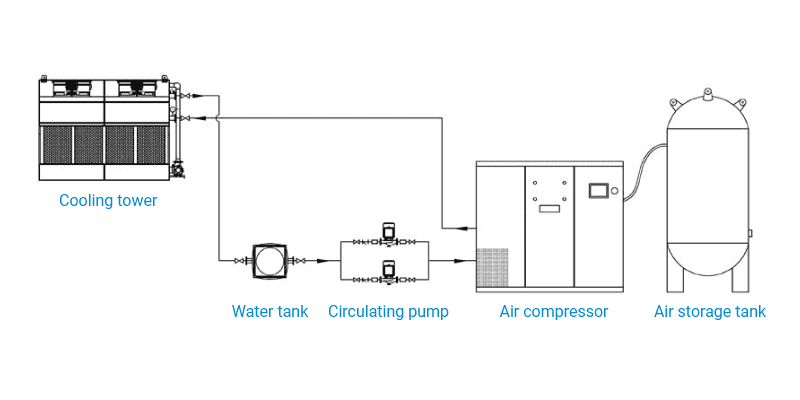

Pumps are the heart of any cooling tower auxiliary system. They circulate water from the basin through the tower and back to the process. Key points include:

Choosing the right pump size and type (centrifugal, vertical, or horizontal)

Ensuring consistent flow and pressure

Minimizing energy losses with high-efficiency motors

Reliable pumps also prevent system downtime and uneven cooling, which can affect overall plant performance.

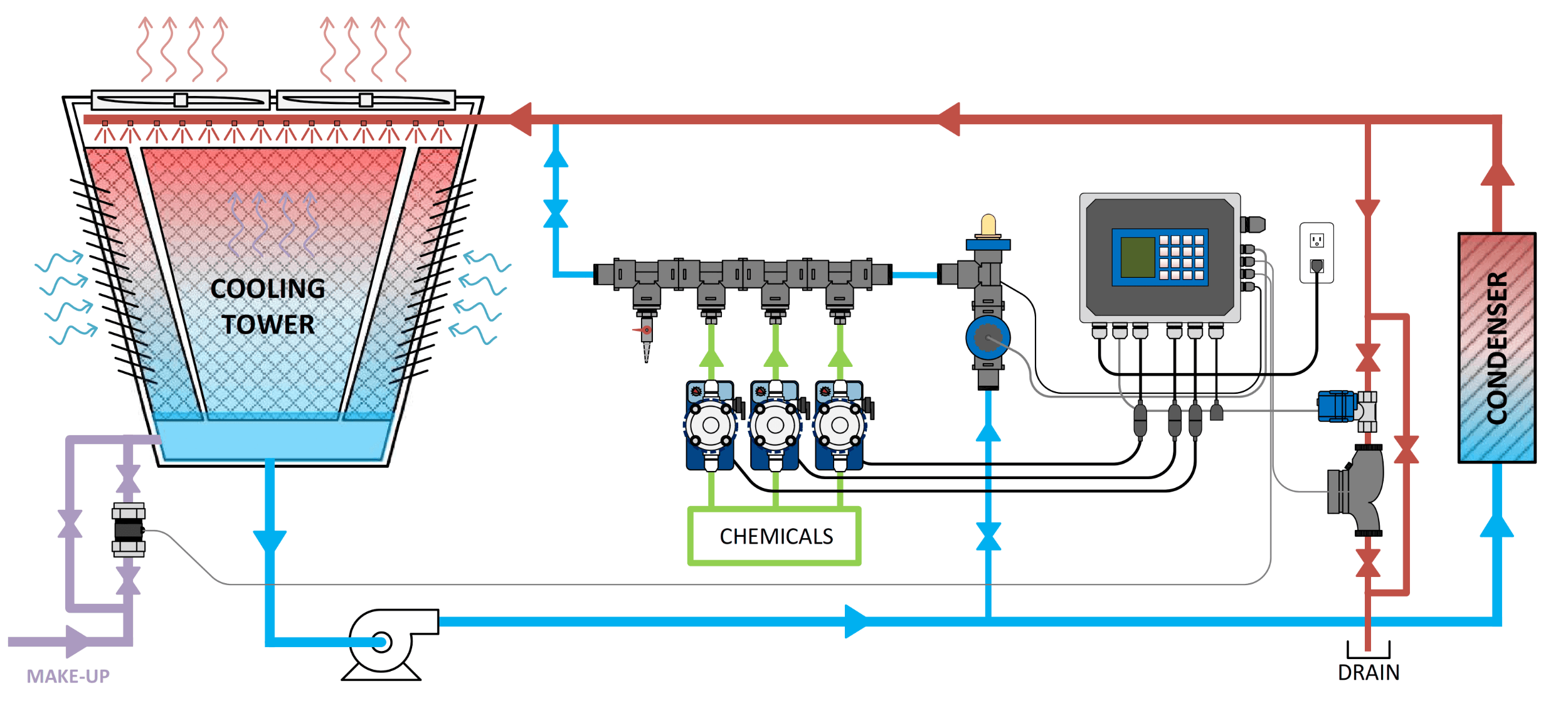

Water quality is essential for preventing scale, corrosion, and microbial growth. Auxiliary equipment includes:

Chemical dosing systems

Filtration units

Water softeners and blowdown systems

Maintaining water chemistry protects both the tower and connected process equipment, saving long-term costs.

Valves and piping are the circulation pathways of the auxiliary system. They ensure correct flow distribution and provide control points for maintenance. Considerations include:

Material selection for corrosion resistance

Proper valve sizing and types (ball, butterfly, or globe valves)

Minimizing pressure drops and turbulence

Modern cooling towers rely on instrumentation for real-time monitoring:

Temperature and pressure sensors

Flow meters

Conductivity and pH sensors

These devices feed data to the control system, allowing operators to optimize performance and detect issues before they escalate.

Electrical and automation systems manage auxiliary equipment:

Motor starters and VFDs

Programmable logic controllers (PLC)

Alarm and shutdown systems

Automation reduces human error, improves efficiency, and ensures safe operation under varying load conditions.

These towers require auxiliary equipment to maintain proper airflow and water distribution. VFDs often control the fan speed, while multiple pumps manage circulation.

Forced draft systems rely heavily on fan motors and control panels for performance. Auxiliary piping and valves are optimized for maintaining even water flow across fill sections.

Hybrid towers combine wet and dry cooling technologies. Auxiliary equipment includes both standard circulation systems and heat exchangers for dry sections.

Regular inspection is essential to:

Detect leaks, corrosion, and wear

Ensure pumps, valves, and sensors are operational

Keep chemical dosing and filtration units clean

A well-maintained auxiliary system reduces unplanned downtime.

Pumps and motors need proper lubrication schedules. Bearings, seals, and moving parts must be checked regularly to prevent premature failures.

Sensors and meters require periodic calibration to ensure accurate readings. Incorrect data can lead to water chemistry issues, inefficient operation, or even equipment damage.

VFDs allow pumps and fans to adjust speed based on real-time demand, significantly reducing energy use and improving system responsiveness.

Advanced automation can monitor flow, temperature, and water chemistry, adjusting auxiliary systems automatically for optimal efficiency.

Auxiliary equipment also plays a crucial role in safety:

Preventing overpressure or dry-run conditions

Managing chemical dosing safely

Complying with environmental regulations and water discharge standards

Properly designed auxiliary systems help meet international compliance requirements.

When choosing a manufacturer, look for:

ISO-certified processes

CTI performance-verified components

Proven track record in industrial installations

This ensures reliability and global compliance.

Mach Cooling (https://www.machcooling.com/) provides comprehensive auxiliary solutions:

High-efficiency circulation pumps

Automated chemical dosing systems

Integrated PLC and control panels

Full-service design, installation, and maintenance support

Their focus on quality and compliance makes them a trusted choice worldwide.

Integration with IoT and remote monitoring

Smart predictive maintenance systems

Advanced energy-efficient pumps and motors

Eco-friendly chemical and water treatment solutions

The future of auxiliary equipment is smarter, greener, and more automated.

Auxiliary cooling tower equipment may not be the most visible part of your system, but it’s arguably the most important. From pumps to sensors, from water treatment units to automation panels, these components ensure your cooling tower operates efficiently, safely, and reliably.

Manufacturers like Mach Cooling combine cutting-edge technology, compliance with international standards, and practical engineering expertise to deliver complete auxiliary solutions. Investing in high-quality auxiliary equipment isn’t optional—it’s essential for long-term performance, energy efficiency, and peace of mind.

Cooling Tower Inspection Services: Ensuring Efficiency And Safety

Cooling Tower Lightning Protection: Essential Safety Measures

How To Choose The Right Cooling Tower Float Switch for Your System

Cooling Tower Factory Insights: Production, Quality, And Innovation

Types of Cooling Tower Casing Materials: FRP Vs Metal Vs PVC

Top 10 Best Cooling Tower Companies in India (2026 Updated List)

Sustainable Cooling Towers: Balancing Evaporation And Water Use