We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-13 Origin: Site

Installing a cooling tower level sensor may seem simple, but it plays a critical role in ensuring your system operates efficiently and safely. A properly installed sensor prevents water overflow, pump damage, and inefficient cooling, saving time, energy, and money. In this guide, we’ll walk through the entire process, from understanding sensors to installation and maintenance, with insights from Mach Cooling.

Cooling towers rely on precise water levels to operate efficiently. Too little water can damage pumps, while too much water wastes resources and reduces efficiency. Level sensors act as the system’s eyes, continuously monitoring water levels and ensuring the tower maintains optimal performance.

A cooling tower level sensor is a device that detects the water level in the basin. When water rises or falls beyond a set point, the sensor triggers actions such as:

Starting or stopping pumps

Sending alerts to operators

Controlling automated top-up systems

With accurate water level monitoring, you can:

Avoid pump dry-run damage

Reduce water overflow and wastage

Ensure consistent cooling efficiency

Simple and reliable

Cost-effective

Suitable for most standard cooling tower systems

High precision and sensitivity

Low maintenance

Ideal for chemically treated or corrosive water

Contactless measurement

Detect water levels in challenging environments

Compatible with advanced control systems

Vertical: Moves up and down with water level, common in deep basins

Horizontal: Pivots with water level, suitable for shallow or wide basins

Consider:

Basin size and depth

Pump configuration

Environmental factors (temperature, chemical exposure)

Sensor materials must withstand:

Chlorine and biocides

pH fluctuations

Hard water scaling

Disconnect electrical power

Wear PPE (gloves, goggles)

Ensure a stable working platform

Screwdrivers and wrenches

Drill and mounting hardware

Electrical connectors and wires

Sensor manufacturer’s installation manual

Place the sensor in a debris-free area

Ensure float or probe moves freely

Avoid corners or areas prone to sediment accumulation

Connect according to the manufacturer’s diagram

Use waterproof connectors for long-term reliability

Check polarity and voltage ratings

Verify the sensor triggers pumps or alarms at correct water levels

Adjust float or probe positions if needed

Test multiple cycles to ensure reliability

Improper positioning causing false readings

Loose electrical connections

Neglecting calibration after installation

Installing in high-debris areas

Remove debris or sediment from the basin

Check float movement or probe alignment

Inspect electrical connections

Sensor not triggering → check wiring and calibration

False readings → clean float/probe and remove obstructions

Corrosion → replace damaged components with compatible materials

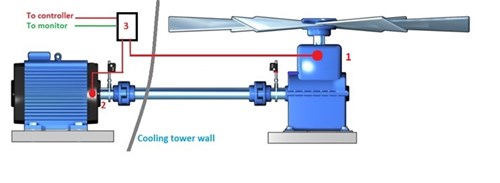

Level sensors can automate:

Pump start/stop sequences

Water top-up systems

Alarms for high/low water levels

Modern sensors allow:

Real-time remote monitoring

Integration with SCADA or PLC systems

Predictive maintenance using data trends

Mach Cooling (https://www.machcooling.com/) provides:

Mechanical and electronic level sensors

Professional installation and calibration services

Integration with automated control systems

Detailed reporting and maintenance guidance

Clients report increased reliability, reduced downtime, and energy savings after implementing Mach Cooling solutions.

Smart sensors with IoT and cloud connectivity

AI-based predictive maintenance for water systems

Integration with energy management and sustainability platforms

Installing a cooling tower level sensor correctly is critical for safe, efficient, and reliable operation. From choosing the right type to proper positioning, wiring, and calibration, every step matters. Partnering with experienced providers like Mach Cooling ensures your sensors function optimally, helping you prevent downtime, reduce water waste, and maximize energy efficiency.

Cooling Tower Inspection Services: Ensuring Efficiency And Safety

Cooling Tower Lightning Protection: Essential Safety Measures

How To Choose The Right Cooling Tower Float Switch for Your System

Cooling Tower Factory Insights: Production, Quality, And Innovation

Types of Cooling Tower Casing Materials: FRP Vs Metal Vs PVC

Top 10 Best Cooling Tower Companies in India (2026 Updated List)

Sustainable Cooling Towers: Balancing Evaporation And Water Use