We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-11-26 Origin: Site

In modern thermal power plants—including coal-fired, gas-fired, and nuclear power stations—an enormous amount of waste heat is produced during electricity generation. To safely and efficiently release this heat into the atmosphere and to cool and recycle circulating water, the cooling tower is an essential piece of equipment.

This article explains the basic working principle of cooling towers, their types and structures, their role in power plants, and the importance of professional manufacturers such as Mach Cooling (https://www.machcooling.com/).

A cooling tower is a heat-rejection device that removes waste heat from industrial or power plant processes by allowing hot water to come into direct contact with air. In short, it is a giant heat exchanger—not for cooling air, but for cooling water.

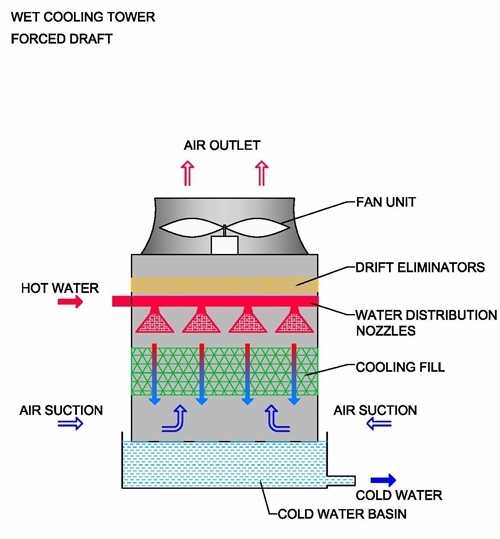

Most cooling towers use evaporative cooling:

Hot circulating water is pumped to the top of the tower.

Spray nozzles distribute the water onto fill media, creating thin water films or droplets.

Air is drawn into the tower (by natural draft or mechanical fans).

A small portion of water evaporates.

The evaporation process absorbs large amounts of heat (latent + sensible heat), reducing the water temperature rapidly.

The cooled water is collected at the bottom basin and pumped back into the system.

In simple terms:

Hot water + cool air → partial evaporation → heat removed → cold water → recirculation.

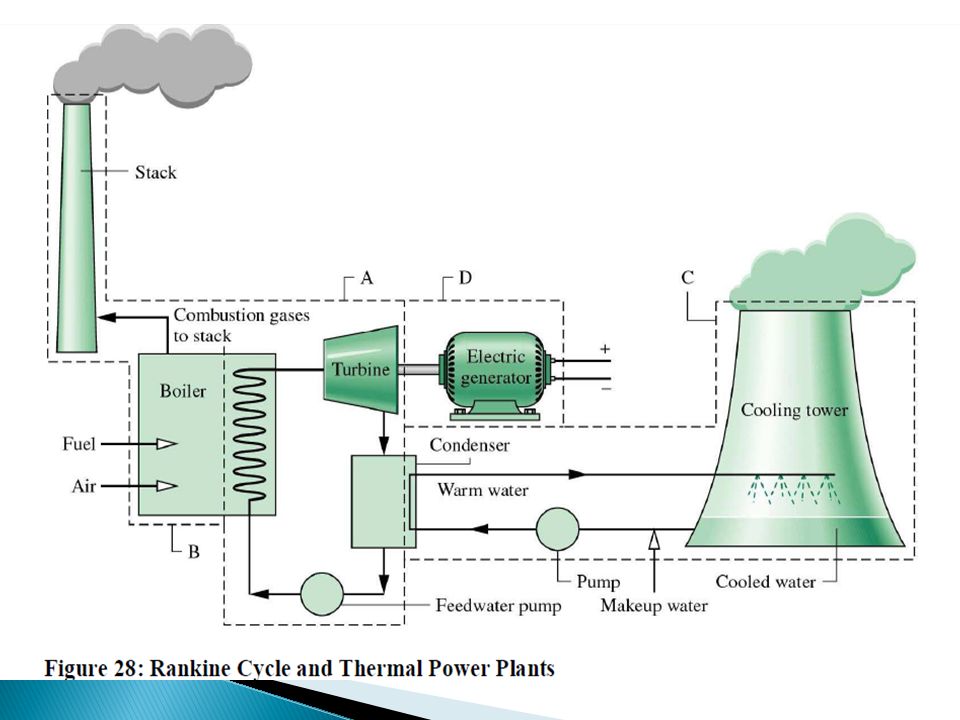

In power plants, after steam drives the turbine to generate electricity, it must be condensed back into water in the condenser. During condensation, steam transfers heat into the circulating cooling water, warming it up.

Without cooling the water, its temperature would rise continuously, reducing condenser efficiency and threatening plant safety.

The cooling tower rejects this waste heat to the atmosphere, producing the familiar "white plume" above power plant towers.

The cooled water is then reused in the condenser, ensuring continuous and stable power generation.

Compared with discharging hot water directly into rivers or lakes—which can damage aquatic ecosystems—cooling towers are far more energy-efficient and environmentally friendly.

They also reduce the demand for fresh water, which is critical in water-scarce regions.

Water flows vertically downward; air flows horizontally through the fill. This structure distributes water well and is suitable for splash cooling.

Air flows upward from the bottom; water flows downward from the top. Air and water move in opposite directions, maximizing heat transfer efficiency.

Typically large hyperbolic structures

Rely on natural convection from hot air rising

Common in large power plants

Use fans to force or induce airflow

Suitable when space or environmental constraints exist

Water directly contacts air

Most common in power plants

Water and air do not directly mix

Suitable for clean-water or pollution-sensitive applications

Assuming Mach Cooling (https://www.machcooling.com/) is a professional cooling tower manufacturer, it brings significant value in the following aspects:

Customized Cooling Tower Design

Tailored to power plant size, heat load, climate, water source, layout, etc.

High-quality Materials & Construction

Especially important for large hyperbolic towers.

High Efficiency & Energy Saving

Optimized fill, air paths, drift eliminators, and spray systems.

Complete System Solutions

Cooling tower + circulation pumps + fans + fill media + water treatment.

Reliable manufacturers significantly affect a power plant’s efficiency, stability, and long-term operating cost.

| Step | Description |

|---|---|

| 1 | Steam after turbine work is cooled in the condenser, transferring heat to circulating water. |

| 2 | Hot water is pumped to the cooling tower’s top spray system. |

| 3 | Air flows into the tower; part of the water evaporates and removes heat. |

| 4 | Water temperature decreases rapidly and collects in the basin. |

| 5 | Cooled water returns to the condenser to begin a new cycle. |

This cycle repeats continuously to ensure stable, efficient power generation.

Cooling towers are indispensable in power plants and large industrial systems. They use evaporative cooling and air–water heat exchange to release waste heat to the atmosphere and regenerate cool water for reuse.

Choosing an experienced manufacturer like Mach Cooling is crucial for ensuring cooling efficiency, system stability, energy savings, and long-term operational reliability.

Cooling Tower Inspection Services: Ensuring Efficiency And Safety

Cooling Tower Lightning Protection: Essential Safety Measures

How To Choose The Right Cooling Tower Float Switch for Your System

Cooling Tower Factory Insights: Production, Quality, And Innovation

Types of Cooling Tower Casing Materials: FRP Vs Metal Vs PVC

Top 10 Best Cooling Tower Companies in India (2026 Updated List)

Sustainable Cooling Towers: Balancing Evaporation And Water Use