Views: 0 Author: Site Editor Publish Time: 2026-02-05 Origin: Site

When people talk about cooling tower energy efficiency, they often focus on motors, fans, or control systems. But here’s the reality: everything starts with heat transfer. If heat transfer is inefficient, even the most advanced equipment will struggle to deliver real energy savings.

Think of a cooling tower as a carefully choreographed dance between hot water and moving air. When that interaction is smooth and balanced, heat leaves the system effortlessly. When it isn’t, energy consumption rises, operating costs increase, and equipment wears out faster than it should.

A cooling tower exists for one primary purpose—to transfer heat from water to air. Energy efficiency is simply the outcome of how well that heat transfer process works.

When heat transfer surfaces are clean, airflow is well managed, and water is evenly distributed, the cooling tower performs efficiently with minimal energy input. When those conditions deteriorate, efficiency losses follow quickly, often without obvious warning signs.

Before diving into energy efficiency, it’s essential to understand how heat actually moves inside a cooling tower.

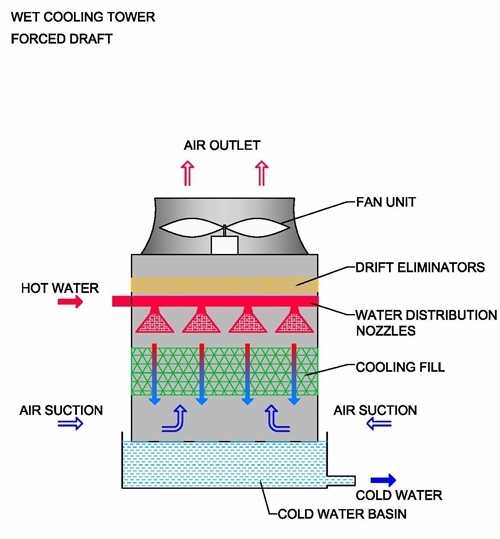

Cooling towers rely mainly on convection and evaporation. Hot process water flows over fill surfaces while air passes through, absorbing and carrying away heat.

Most cooling happens through latent heat transfer, where a small portion of water evaporates. This phase change removes a large amount of heat, making evaporation the powerhouse behind cooling tower performance.

Cooling towers don’t “cool” water in the traditional sense. Instead, they create ideal conditions for heat to escape.

As water evaporates, it pulls heat out of the remaining water. Even a small amount of evaporation can remove significant thermal energy.

Efficient cooling depends on how well air and water interact. Poor contact means less evaporation, less heat transfer, and higher energy use.

Heat transfer efficiency and energy efficiency are inseparable.

When heat transfer improves, fans don’t need to run at full speed, pumps encounter less resistance, and chillers downstream operate under reduced load. The entire system consumes less power.

Blocked airflow, fouled fill, or uneven water distribution can increase energy consumption by double-digit percentages—often without triggering alarms or immediate failures.

Several cooling tower components work together to enable effective heat transfer.

Fill media creates the surface where air and water meet. Well-designed fill maximizes contact area while maintaining low airflow resistance.

Uniform water distribution ensures all fill surfaces participate in heat exchange. Dry spots equal wasted potential.

Fans must deliver the right volume of air at the right pressure. Too little airflow limits evaporation; too much wastes energy.

Water quality plays a critical—but often underestimated—role in energy efficiency.

Scale and fouling act like insulation on heat transfer surfaces. Even thin deposits can dramatically reduce thermal performance.

Proper water treatment helps maintain clean surfaces, protects materials, and preserves long-term heat transfer efficiency.

Some efficiency losses are subtle but costly over time.

Clogged nozzles or poor basin design can lead to uneven water flow, reducing effective heat transfer area.

When air bypasses the fill or exits too quickly, fan energy is wasted without delivering cooling.

Improving heat transfer doesn’t always require major system upgrades.

Choosing the right fill type for the application improves heat exchange while minimizing pressure drop and fouling risk.

Fan selection, shrouds, louvers, and tower geometry all play a role in keeping airflow efficient and controlled.

Clean heat transfer surfaces restore performance immediately. Routine cleaning is one of the most cost-effective efficiency measures available.

Modern cooling towers use smart design and control technologies to maximize efficiency.

Advanced fill designs offer greater surface area, improved wetting, and better resistance to fouling.

VFDs allow fans to adjust speed based on real-time heat load, reducing unnecessary energy consumption during part-load operation.

Cooling tower requirements vary by industry and application.

High heat loads demand robust fill designs, stable airflow, and reliable water distribution.

Energy efficiency at part load is critical, making precise heat transfer control especially important.

Heat transfer efficiency begins long before the cooling tower is installed.

As a professional cooling tower manufacturer, Mach Cooling designs systems with heat transfer efficiency at the core. Engineered fill layouts, uniform water distribution, and optimized airflow paths help customers reduce power consumption while maintaining reliable cooling performance. Learn more at https://www.machcooling.com/.

A manufacturing facility experienced rising energy costs despite stable production. After upgrading fill media and restoring proper water distribution, heat transfer efficiency improved significantly. Fan speeds were reduced, and the facility saw immediate energy savings—without replacing motors or control systems.

Cooling tower energy efficiency is not about chasing the latest technology—it’s about mastering heat transfer fundamentals. When air and water interact efficiently, energy use naturally falls into place.

By maintaining clean surfaces, balanced airflow, proper water distribution, and choosing well-designed systems from experienced manufacturers like Mach Cooling, facilities can achieve sustainable energy savings that last for years, not just months.