We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-06 Origin: Site

Selecting the right filtration system for a cooling tower might seem straightforward, but in reality, it’s a critical decision that impacts performance, water quality, energy efficiency, and operational costs. With so many options on the market, making an informed choice ensures your tower runs smoothly, lasts longer, and saves money in the long run. In this article, we’ll walk you through everything you need to know about choosing the right cooling tower filtration system—from understanding filtration principles to installation and maintenance, all explained in an easy, conversational style.

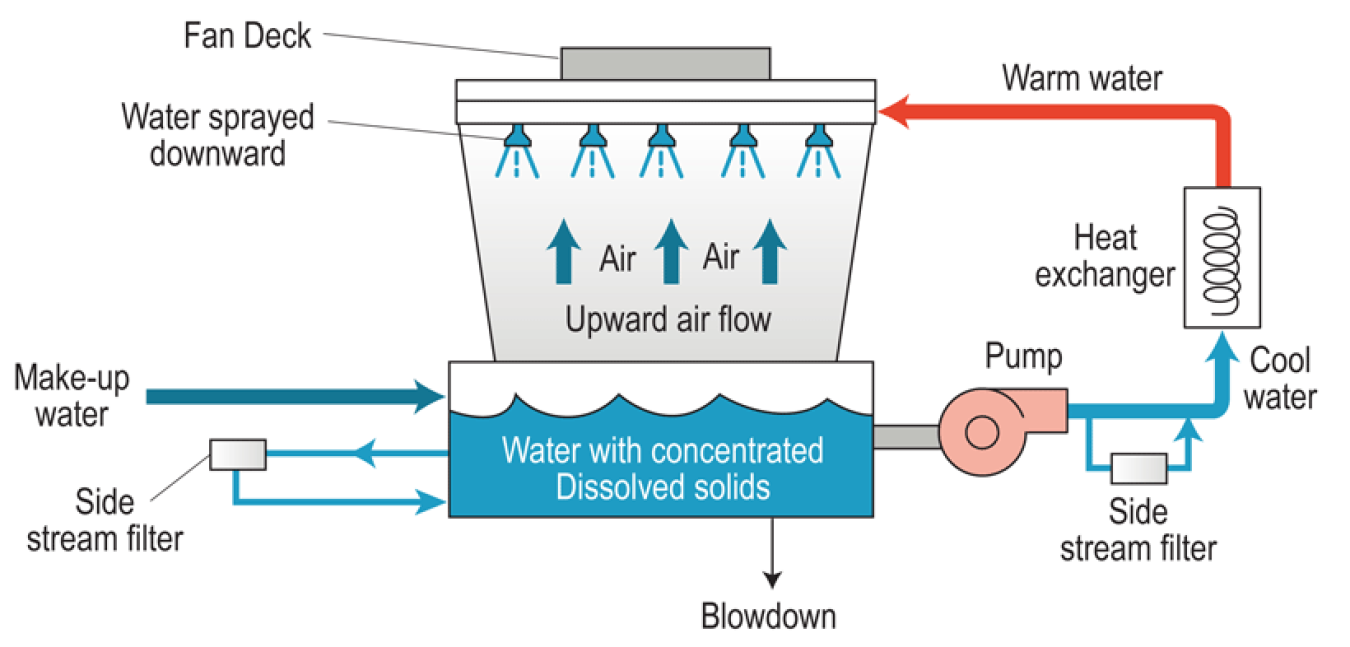

Cooling towers are constantly recirculating water, which inevitably picks up dirt, debris, scale, and biological contaminants. Without proper filtration, this debris can clog nozzles, reduce heat transfer, and shorten the life of your equipment. A proper filtration system:

Maintains water cleanliness

Improves heat exchange efficiency

Reduces maintenance costs

Enhances overall system longevity

Choosing the right system is not just about picking a filter—it’s about matching your tower’s operational needs, water quality, and budget.

Before selecting a system, it’s important to understand the types of filtration commonly used in cooling towers.

Mechanical filters physically remove particles using screens, mesh, or cartridges. They are ideal for:

Preventing debris from entering the tower basin

Reducing sediment accumulation

Protecting pumps and nozzles

These use sand, multi-media layers, or granular activated carbon to trap contaminants. They are excellent for:

Fine particle removal

Turbidity control

Extended protection for larger towers

Advanced systems like self-cleaning drum filters continuously remove debris without manual intervention, ensuring high efficiency and minimal downtime.

Choosing the right filter requires evaluating multiple factors.

Is the water hard, soft, or high in suspended solids?

Municipal water, river water, or recycled water each has different filtration needs.

Larger towers require higher-capacity filters.

Flow rate dictates the type and size of the filtration system.

Outdoor towers exposed to dust, leaves, or industrial contaminants may need coarser pre-filters and robust designs.

Indoor towers may have lower debris levels but still require fine filtration.

Can your staff perform regular filter cleaning?

Automated systems may be better for sites with limited maintenance resources.

Filters can create head loss; excessive resistance increases pump energy consumption.

Low-pressure-drop systems are more energy-efficient.

Begin by testing water for:

Total suspended solids (TSS)

Turbidity

Biological load

pH and hardness

This helps determine whether mechanical filtration alone is sufficient or if additional media filtration is required.

Ask yourself:

Are you aiming to protect nozzles and pumps?

Do you need to reduce biological growth?

Is the goal to improve heat transfer efficiency?

Your objectives will guide whether a single-stage mechanical filter, media filter, or combined system is ideal.

Easy to install and maintain

Ideal for large debris like leaves and sticks

Less effective for fine sediment

Remove fine particles down to a few microns

Require regular cleaning or replacement

Suitable for small to medium towers

Excellent for high TSS water

Handles variable water quality well

Can be combined with chemical treatment for added protection

Continuous operation with minimal manual intervention

High reliability in debris-heavy environments

Reduces labor and maintenance downtime

Space availability around the tower

Access for maintenance and inspection

Piping modifications or integration with existing water treatment systems

Electrical requirements for automated systems

Proper planning during installation avoids costly modifications and ensures seamless integration.

Filtration systems aren’t just a one-time investment—they have ongoing costs:

Filter media replacement

Cleaning and maintenance labor

Energy costs due to head loss

Potential chemical savings from improved water quality

Choosing a system with a balance of upfront and operational costs is crucial for ROI.

A high-quality manufacturer ensures:

Proper system sizing and design

Long-term durability and warranty

Technical support for installation, operation, and troubleshooting

Mach Cooling, for example, provides expert-engineered filtration solutions tailored for industrial and commercial cooling towers. Their systems are designed for easy maintenance, high debris handling, and energy efficiency. Learn more at https://www.machcooling.com/.

Regular inspections ensure filters are functioning optimally

Cleaning schedules vary based on water quality and debris load

Automated systems reduce labor but still require periodic checks

Monitoring differential pressure across the filter helps detect clogging early

Filtration complements chemical water treatment

Reduces scale, corrosion, and biological growth

Helps maintain consistent cooling performance and water quality

Ensure the system meets local environmental regulations for water discharge and treatment

Efficient filtration minimizes water wastage and chemical usage

Low-resistance filters reduce pump energy consumption

Self-cleaning and automatic backwash systems help maintain low head loss

Proper filtration ensures fans and pumps operate efficiently by maintaining heat transfer performance

A large industrial facility installed a self-cleaning drum filtration system from Mach Cooling. After installation:

Debris in the tower basin decreased by 90%

Heat transfer efficiency improved by 12%

Water and energy consumption were significantly reduced

Maintenance labor dropped by over 50%

This demonstrates how selecting the right filtration system directly impacts operational efficiency and cost savings.

Choosing the right cooling tower filtration system requires careful consideration of:

Water quality

Tower size and flow rate

Debris load and environmental exposure

Maintenance capabilities

Energy efficiency goals

By selecting a high-quality system from an experienced manufacturer like Mach Cooling, you can ensure long-lasting performance, reduced operating costs, and optimized heat transfer efficiency.

Investing in the right filtration system is investing in the long-term reliability and efficiency of your cooling tower. With proper assessment, installation, and maintenance, you can maximize performance and minimize problems for years to come.