We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-06 Origin: Site

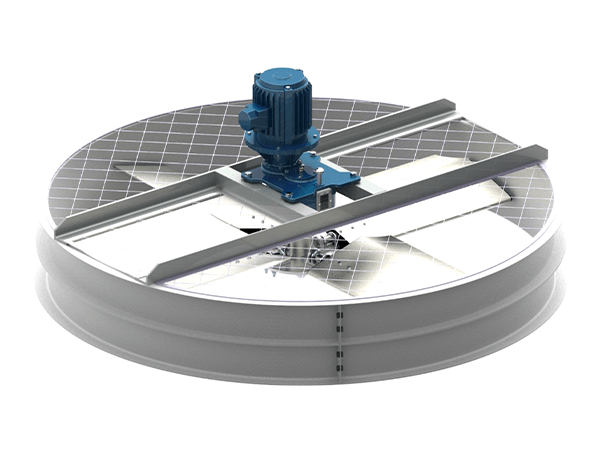

Cooling towers are the heart of commercial and industrial HVAC systems, and their efficiency depends heavily on every component working flawlessly. One of the most critical yet often overlooked parts is the gear reducer. Without proper maintenance and monitoring, gear reducers can fail prematurely, causing costly downtime and reducing the overall performance of the cooling system.

In this comprehensive guide, we’ll explore everything about cooling tower gear reducer maintenance and performance, including types, maintenance strategies, performance optimization, common issues, and how Mach Cooling ensures long-lasting, high-efficiency gear reducer solutions.

A cooling tower gear reducer transfers power from the motor to the fan while controlling speed and torque. Essentially, it ensures that fans operate at the right speed to maximize heat transfer. Poor performance or failure of a gear reducer can lead to:

Inconsistent airflow

Reduced cooling efficiency

Increased energy consumption

Unexpected downtime and costly repairs

Regular maintenance and correct operation are essential for keeping your cooling tower running smoothly.

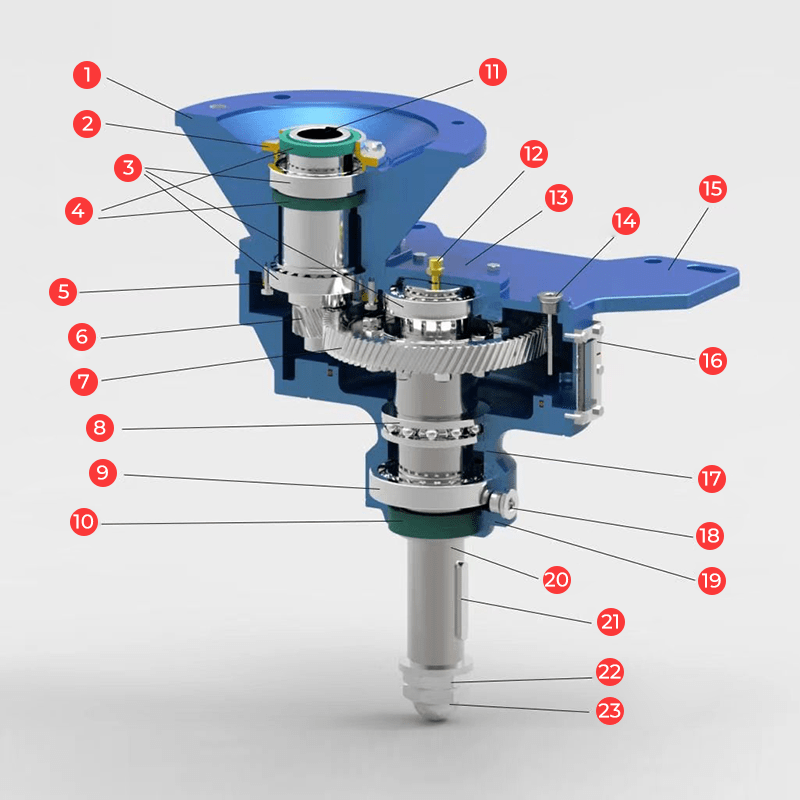

A gear reducer, or gearbox, is a mechanical device that reduces the motor’s high speed while increasing torque. It allows large cooling tower fans to operate efficiently at lower speeds without overloading the motor.

Receives high-speed input from the motor

Uses gears to reduce speed and increase torque

Drives the fan for consistent airflow and optimal heat rejection

Smooth and quiet operation

High efficiency for continuous use

Commonly used in commercial towers

Excellent for high-torque, right-angle applications

Compact design for space-constrained installations

High load capacity

Suitable for large industrial towers with heavy-duty fans

Durable and reliable for long-term operation

Temperature Rise: Excess heat can indicate overload or lubrication issues.

Noise Levels: Unusual noise may signal gear misalignment or wear.

Vibration: Increased vibration reduces efficiency and accelerates wear.

Lubricant Condition: Degraded oil impacts gear life and efficiency.

Output Speed Accuracy: Ensures proper fan rotation and airflow.

Use the manufacturer-recommended gear oil.

Monitor oil levels and top up as necessary.

Check for contamination, water ingress, or metal particles.

Inspect gears, bearings, and seals for wear or damage.

Look for misalignment, loose bolts, or unusual noise.

Check coupling and motor alignment to prevent stress on gears.

Conduct oil analysis to detect early signs of wear.

Replace oil at intervals specified by the manufacturer or based on operating conditions.

Install temperature sensors to monitor gear oil and housing.

Overheating indicates overloading or lubrication issues.

Periodically measure vibration levels.

Identify imbalance, misalignment, or gear damage before failure occurs.

Caused by inadequate lubrication or contamination

Solution: Replace worn gears and maintain proper oil quality

Resulting from misalignment or excessive load

Solution: Realign shafts and replace bearings promptly

Leads to oil loss and contamination

Solution: Replace seals and inspect for proper installation

Can be caused by overload, poor lubrication, or blocked airflow

Solution: Check load, improve ventilation, and monitor oil temperature

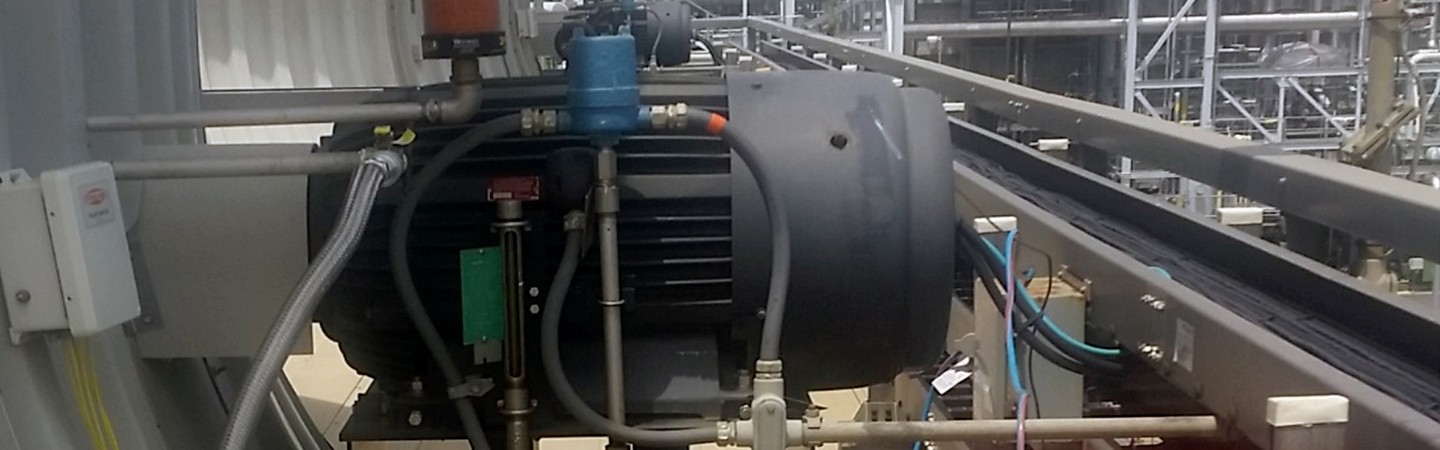

Correct alignment of motor, gearbox, and fan is essential

Misalignment causes stress, vibration, and premature wear

Avoid overloading the reducer

Ensure fan and tower operate within design parameters

High-efficiency reducers reduce power loss

Correct sizing prevents motor overworking and energy waste

Install reducers in protected areas to avoid dust, water, and corrosion

Use seals and protective coatings when necessary

Mach Cooling provides industry-leading gear reducers designed for durability, high efficiency, and minimal maintenance:

Helical, bevel, and planetary gear reducers for different tower sizes

High-quality lubrication systems to extend service life

Vibration and temperature monitoring integration

Customizable solutions for commercial and industrial cooling towers

Expert technical support and maintenance guidance

Learn more at https://www.machcooling.com/.

A high-rise office building replaced its aging gear reducers with Mach Cooling helical gear reducers. Results included:

20% improvement in fan efficiency

Significant reduction in maintenance downtime

Lower energy consumption due to optimal speed and torque

Reliable performance throughout multiple winter and summer cycles

Follow manufacturer maintenance schedules

Conduct regular inspections for wear, vibration, and noise

Use only recommended lubricants and replace at intervals

Monitor operating temperature and load conditions

Keep detailed maintenance logs for troubleshooting and performance tracking

Unusual noise or whining

Excessive vibration or wobbling

Overheating of housing or oil

Oil leaks or contamination

Inconsistent fan speed or airflow

A properly maintained gear reducer is essential for ensuring cooling tower reliability, efficiency, and longevity. By implementing a comprehensive maintenance plan, monitoring performance indicators, and using high-quality gear reducers like those from Mach Cooling, operators can prevent costly downtime, improve energy efficiency, and extend equipment life.

Investing in maintenance and professional-grade gear reducers pays off with stable cooling performance, lower operational costs, and fewer emergency repairs, making it a cornerstone of any commercial or industrial HVAC system.