We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-05 Origin: Site

Cooling towers are vital components in industrial and commercial HVAC systems, playing a key role in dissipating heat from water-cooled processes. Integral to their performance is the heat exchanger, which allows efficient heat transfer while protecting the system from contamination. Choosing the right type of heat exchanger is crucial to maximize efficiency, reduce maintenance, and prolong equipment life.

In this article, we will explore the types of cooling tower heat exchangers, their principles, advantages, challenges, and maintenance practices, while highlighting solutions from Mach Cooling, a leading manufacturer of high-performance cooling systems.

A heat exchanger in a cooling tower separates two fluid streams—usually water and a process fluid—allowing heat transfer without mixing. This ensures:

Protection against contamination of the main cooling water

Improved system reliability

Efficient heat removal

Reduced maintenance and downtime

Without an effective heat exchanger, cooling towers may suffer from scaling, corrosion, and inefficient heat rejection, increasing energy consumption.

Two fluids flow in separate channels

Heat moves from the warmer fluid to the cooler fluid

Designs optimize surface area and flow rates to maximize efficiency

Heat transfer coefficient

Pressure drop

Flow arrangement (counterflow, parallel flow, crossflow)

Material compatibility

Composed of a bundle of tubes within a shell

Process fluid flows inside the tubes while cooling water flows outside

Can handle high pressures and temperatures

Durable and widely used in industrial applications

Advantages:

High capacity

Robust for industrial conditions

Easy to maintain

Challenges:

Larger footprint

Potential for fouling if water quality is poor

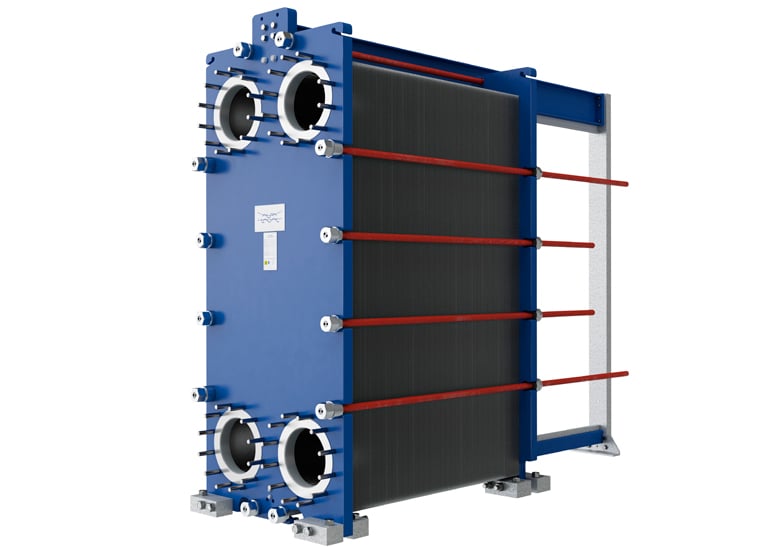

Comprise thin, corrugated plates stacked together

Fluids flow in alternating channels

Compact design with high heat transfer efficiency

Advantages:

Small footprint, ideal for space-constrained installations

High efficiency with low water volume

Easy to disassemble and clean

Challenges:

Sensitive to scaling and fouling

Gasket maintenance required

Variation of plate heat exchangers with removable plates and gaskets

Allows easy inspection and cleaning

Often used in commercial cooling towers and HVAC systems

Advantages:

Flexible capacity by adding or removing plates

Easy maintenance and repair

Challenges:

Gaskets may degrade over time

Not ideal for extremely high-pressure applications

Fluids flow in a spiral channel

Self-cleaning effect reduces fouling

Compact design for moderate capacities

Advantages:

Low fouling tendency

Efficient for viscous fluids or fluids with particles

Challenges:

Limited size options

Less common in very large industrial cooling towers

Uses air as the cooling medium instead of direct water contact

Often combined with dry or hybrid cooling towers

Suitable for water-constrained regions

Advantages:

Reduces water consumption

Can operate in cold climates without freezing

Challenges:

Less efficient than wet cooling

Larger footprint required

Hot process fluid may require stainless steel or high-alloy materials

Cooling water quality impacts fouling and corrosion

Plate exchangers for tight spaces

Shell-and-tube for large industrial setups

Plate and frame exchangers are easier to maintain

Shell-and-tube may require chemical cleaning or mechanical brushing

High-efficiency exchangers reduce energy consumption

Low pressure drop designs save pump energy

Regular Cleaning: Remove scale and debris to maintain heat transfer efficiency

Water Treatment: Prevent corrosion and fouling using appropriate chemicals

Gasket Inspection: For plate-type exchangers, check gaskets for wear and leaks

Monitoring: Track pressure drop and temperature differences to detect performance issues

Periodic Overhaul: For shell-and-tube units, inspect tubes and replace damaged components

Optimizing heat exchanger design reduces cooling tower runtime

High-efficiency materials and surface designs maximize heat transfer

Integrating with variable-speed fans and smart controls enhances energy savings

Mach Cooling provides reliable and high-performance cooling tower heat exchangers:

Shell-and-tube, plate, and plate-and-frame options

Customizable for commercial and industrial towers

High corrosion resistance and long service life

Expert installation and maintenance support

Learn more at https://www.machcooling.com/.

A large commercial building installed Mach Cooling plate-and-frame heat exchangers on its rooftop towers. Key results included:

Improved heat transfer efficiency by 15%

Reduced water consumption through indirect cooling

Simplified maintenance with removable plates

Reliable operation across summer and winter seasons

Scaling and Fouling: Reduce efficiency and increase pressure drop

Leaks: Gasket degradation or tube failure

Corrosion: Material incompatibility or poor water treatment

Flow Imbalance: Uneven distribution of fluids reduces performance

Choosing the correct cooling tower heat exchanger involves balancing efficiency, maintenance, durability, and cost. Whether you need a shell-and-tube for heavy-duty industrial use, a plate-and-frame for compact commercial applications, or an air-to-water system for water savings, proper selection and maintenance are critical.

Partnering with Mach Cooling ensures reliable performance, high efficiency, and long-term support. Protect your cooling tower investment and optimize heat rejection by selecting the right heat exchanger today.