We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-06 Origin: Site

In today’s industrial landscape, cooling towers are no longer just giant fans blowing water into the air. They’ve evolved into smart, efficient, automated systems—driven by sensors, real-time data, and intelligent control strategies. With rising energy costs, water scarcity concerns, and the push for sustainability, modern cooling tower operation demands more than manual switches and periodic checks.

In this article, we’ll explore smart operation strategies for modern cooling towers—what they are, why they matter, how they work, and how they help facilities save energy, water, and money. You’ll walk away with a practical understanding of how smart systems can transform cooling tower performance.

When we say smart cooling tower operation, we’re talking about using data, automation, and predictive tools to run your tower more efficiently. Instead of reacting after problems show up, smart systems anticipate and optimize performance in real time—much like how a smart thermostat adjusts your home’s temperature for comfort and efficiency.

Why does this matter? Traditional cooling tower operation often runs fans and pumps at full blast all the time—even when cooling demand is low. That leads to energy waste, higher water use, and unnecessary wear on mechanical parts. Smart strategies flip this old model on its head.

Cooling towers can consume a significant portion of a facility’s energy budget. For many systems, fans and pumps are the biggest culprits. But smart controls—especially integration with Variable Frequency Drives (VFDs)—adjust motor speeds based on real-time conditions, eliminating wasted energy and cutting costs.

Water isn’t unlimited. With smart control systems tracking cycles of concentration and evaporation dynamics, operators can conserve makeup water and reduce blowdown losses—helping facilities meet both efficiency and environmental goals.

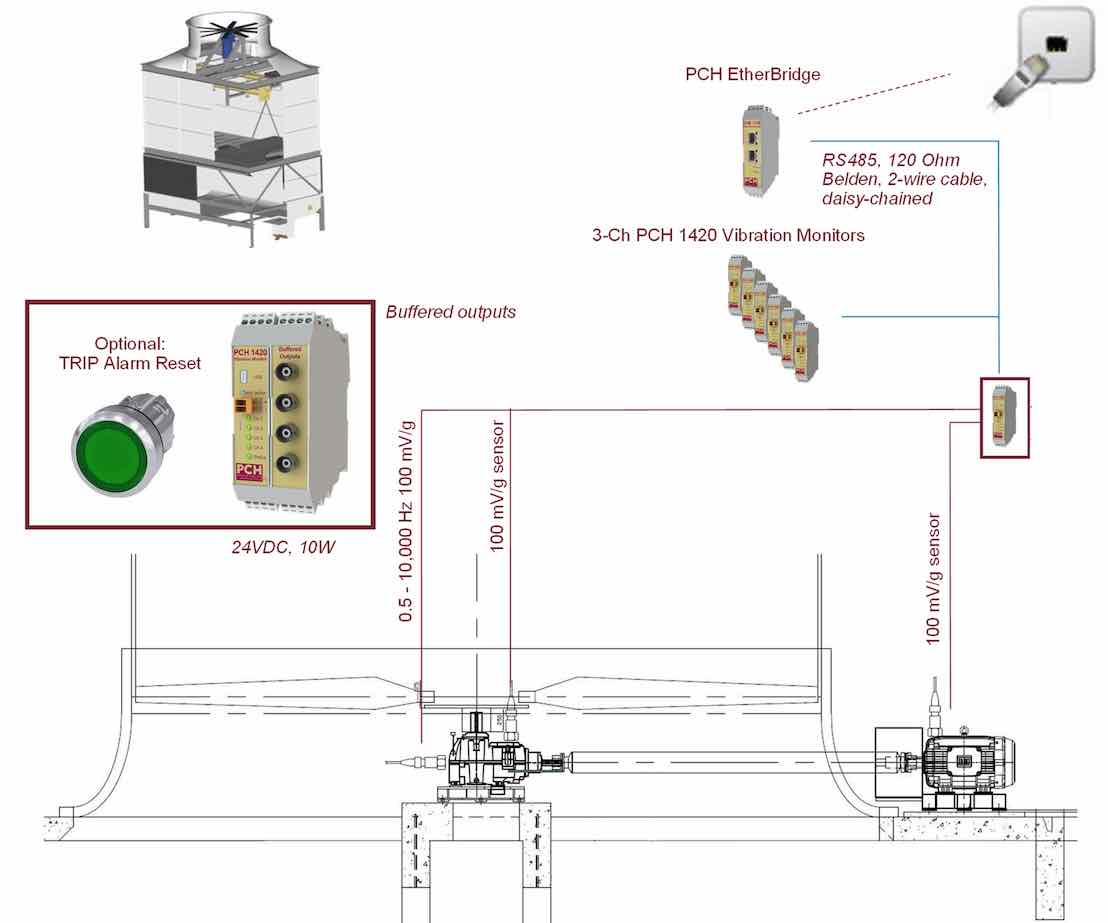

Instead of waiting for breakdowns, smart systems use performance trends and real-time sensor data to anticipate issues—like unusual vibration or temperature spikes—before they lead to costly failures. This increases uptime and reduces unplanned maintenance.

To turn a traditional cooling tower into a smart one, you need several key components working together.

Sensors track temperature, humidity, water flow, conductivity, and fan speed. This data feeds into automated controls that adjust operation based on conditions—not guesswork.

VFDs dynamically change fan and pump speeds to match the actual cooling load instead of running at full speed all the time, delivering 15–50% energy savings in many systems.

Smart controllers interpret sensor data to decide when to adjust cooling modes, water flow, or fan speeds. These systems can respond faster and more precisely than manual operation.

Remote monitoring dashboards let facility managers see performance metrics at a glance, get alerts, and adjust settings without being physically present.

Here are some of the most effective strategies used in smart cooling tower operation today:

Rather than fixed speeds, fans and pumps scale up or down based on temperature differentials and load demand. This prevents energy waste during off-peak periods.

Automatically adjusts fan speed using VFDs

Matches cooling output to real-time need

Reduces wear on motors

Cuts energy bills significantly

Smart systems can switch between different operational modes—like natural cooling or high-efficiency mode—based on ambient conditions and internal loads.

Natural cooling when weather permits

Pre-cooling before peak demand

Peak mode during hot conditions

This keeps the system running efficiently without constant manual adjustments.

With real-time monitoring, operators get instant visibility into system performance and can act before small issues become big problems.

Benefits include:

Early fault detection

Trending analysis helps trace inefficiencies

Alerts when parameters exceed safe thresholds

Remote access to live performance data

Some systems now incorporate machine learning models to predict future performance trends.

Analyze historical and real-time data

Forecast cooling demand shifts

Predict component wear and service needs

Schedule maintenance only when necessary

This proactive approach helps extend equipment life and minimizes unexpected failures.

Cooling towers lose water through evaporation and blowdown. Smart operation systems monitor water quality and adjust chemical dosing and cycles of concentration automatically, reducing:

Chemical waste

Blowdown water quantity

Corrosion and scaling risk

Smart systems are powerful, but they perform best when paired with good operational practices.

Sensors help identify issues early, but basic cleaning—like keeping fill media and drift eliminators clear—ensures the system doesn’t have to fight unnecessary resistance.

Smart systems rely on accurate data. Calibrated sensors ensure decisions are based on reliable information.

Connecting the cooling tower to a broader building management system allows climate control strategies, HVAC operation, and energy-use patterns to be optimized holistically.

Cooling demand can vary wildly throughout a day or season. Smart systems adapt in real time rather than using a one-size-fits-all control logic.

Extreme ambient temperatures or humidity can skew traditional setpoints. Smart systems compensate by factoring real environmental data into control decisions.

Strategic automation reduces both energy consumption and water waste, helping facilities meet sustainability targets without manual intervention.

Leading manufacturers like Mach Cooling are integrating smart operation strategies into their designs and services. At https://www.machcooling.com/, you’ll find cooling towers engineered for:

IoT-ready integration

Advanced controls compatibility

Ease of retrofit for automation

Remote monitoring support

Customized energy-efficient solutions

By working with experienced vendors, operators get not just equipment—but ongoing support, analytics tools, and optimization strategies tailored to their facility’s needs.

A large commercial building upgraded its cooling tower system with smart controls and VFD fans. After implementation:

Energy consumption dropped by 30%

Water usage decreased by 18%

Unplanned maintenance events were reduced by 40%

Operator visibility and control improved dramatically

This example shows how combining smart strategies with automation leads to measurable gains in performance and savings.

The next frontier includes deeper integration with AI, digital twins, and predictive optimization models. These systems won’t just report what’s happening—they’ll anticipate demand shifts and system needs long before operators notice them. This shift from reactive to anticipatory operation represents a major leap in efficiency and reliability.

Smart operation strategies are no longer optional—they’re essential for facilities that want to stay competitive and sustainable. By leveraging real-time monitoring, automation, predictive analytics, and intelligent controls, cooling towers can operate more efficiently, use less water, consume less energy, and require less manual intervention.

If you’re ready to transform your cooling tower’s performance, consider partnering with seasoned manufacturers like Mach Cooling that design systems with smart operation, retrofit capability, and long-term support in mind.

Smart doesn’t just mean automated—it means adaptive, efficient, and future-ready.