Views: 0 Author: Site Editor Publish Time: 2026-02-05 Origin: Site

Replacing cooling tower fill is one of the most critical maintenance tasks for ensuring optimal heat transfer and energy efficiency. While it might sound intimidating, with the right approach, tools, and guidance, the process can be straightforward, safe, and highly effective. In this article, we’ll guide you through the complete step-by-step process of cooling tower fill replacement, along with tips to maximize performance and longevity.

Cooling tower fill is essentially the heart of heat exchange. Over time, fill can become fouled, clogged, or degraded, reducing evaporation efficiency, increasing energy consumption, and even causing system downtime. Replacing the fill ensures the tower operates at peak performance, minimizes water usage, and extends the lifespan of the equipment.

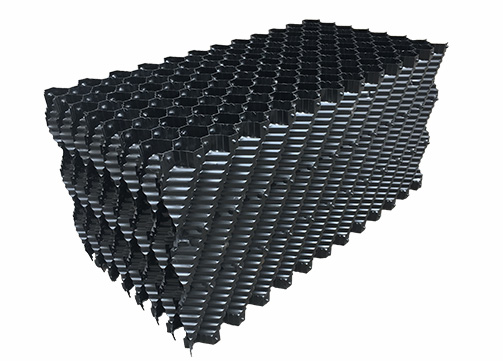

Fill in a cooling tower increases the surface area for water and air to interact, enhancing heat transfer. There are two main types:

Water breaks into droplets to maximize air contact. Ideal for small to medium towers.

Water forms thin films over sheets or corrugated material. Most commonly used in large industrial applications.

Knowing when to replace fill prevents unnecessary downtime and ensures efficiency.

If your tower is no longer achieving design temperatures, fill performance may be degraded.

Algae growth, mineral deposits, or other contaminants indicate the need for replacement.

Structural deterioration of fill media compromises airflow and water distribution.

Fans and pumps working harder than usual often signal poor heat transfer due to aging fill.

Proper preparation ensures safety and efficiency.

Power down all equipment.

Lockout/tagout fans, pumps, and electrical systems.

Wear protective gear, including gloves, goggles, and masks.

Replacement fill (match type and dimensions).

Cutting tools or saws for removing old fill.

Support braces or scaffolding.

Water hoses for cleaning and rinsing.

Before starting, remove all water to prevent slipping hazards and facilitate work.

Use the tower’s drain valves to safely remove water into a designated drainage system.

Wipe down remaining water from basins and sump areas to ensure a dry work environment.

Careful removal protects the tower structure and surrounding equipment.

Many fill sheets are held by support channels or braces—remove carefully.

Film fill may need cutting for removal; splash fill can often be lifted in sections.

Before installing new fill, ensure the interior is clean.

Scrub or pressure-wash the basin and structural supports.

Address any structural issues before proceeding to avoid future failures.

Accurate measurement ensures proper fit and performance.

Match the replacement fill to the tower’s design specifications.

Some fill types come in modular sections for easier installation.

Correct installation is crucial for effective heat transfer.

Align sheets according to airflow direction. Misaligned fill reduces efficiency.

Use support channels, braces, or fasteners as per manufacturer instructions.

Ensure spacing for airflow and water distribution is maintained.

Once fill is installed, complete the structural setup.

Ensure all fill sheets are stable and not shifting.

Nozzles and headers should direct water evenly across the new fill.

With installation complete, bring the tower back online.

Avoid shocking the system with sudden flow.

Observe system performance and check for abnormal noises or vibrations.

Ensure the cooling tower achieves designed cooling load and efficiency.

Routine monitoring extends the life of the new fill.

Check for early signs of fouling or uneven water distribution.

Maintain water chemistry to prevent scale, corrosion, or algae buildup.

Verify that the new fill has restored intended cooling efficiency and lowered fan/pump energy consumption.

Installing fill with incorrect orientation.

Skipping structural inspections before installation.

Neglecting safety protocols.

Reusing damaged or contaminated old fill.

Failing to verify water treatment systems before startup.

Restored heat transfer efficiency.

Reduced energy and water consumption.

Extended cooling tower lifespan.

Minimized risk of unscheduled downtime.

Choosing the right fill and tower design ensures long-term efficiency.

Mach Cooling provides high-quality cooling towers engineered for easy fill replacement and optimal heat transfer. Their design emphasizes:

Modular, easy-to-install fill sheets

Durable materials resistant to fouling and scaling

Optimized airflow paths for maximum evaporation

Learn more at https://www.machcooling.com/.

A large manufacturing facility replaced aged film fill that had been reducing performance for years. After following a structured replacement process:

Cooling efficiency improved by 15%.

Fan and pump energy consumption dropped.

Water treatment issues decreased due to better flow and reduced dead zones.

Cooling tower fill replacement may seem complex, but with proper planning, the right tools, and following a step-by-step approach, it can be done safely and efficiently. Regular inspections, maintenance, and timely replacement of fill ensure your system operates at maximum efficiency, reduces operating costs, and extends equipment lifespan.

By partnering with experienced manufacturers like Mach Cooling, you gain access to expertly engineered towers and fills designed for performance, longevity, and ease of maintenance. Investing in proper fill replacement is investing in your cooling tower’s future.