We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-06 Origin: Site

Cooling towers are workhorses. They take heat, sweat it out, and quietly do their job day in and day out—often without much fanfare. But like any hardworking system, they age. The key to keeping them running longer, more efficiently, and with fewer headaches is preventive care. Think of preventive maintenance as regular checkups for your body: routine care helps you catch small issues before they turn into big problems. The same goes for cooling towers.

You might be thinking, “Maintenance costs money and time—why not just fix things when they break?” It’s a fair question, but here’s the thing: reactive repairs are expensive, disruptive, and often come with unexpected downtime. Preventive care, on the other hand, buys you predictability, efficiency, and extended equipment life. In the long run, it’s a smarter investment.

Before we dig into strategies, let’s talk lifespan. A well-maintained cooling tower can last 20 years or more, but that doesn’t happen by accident. Several factors influence longevity, including environmental conditions, usage intensity, water chemistry, and, most importantly, how you maintain it.

Material quality, design, and installation set the baseline, but ongoing care defines the trajectory. Corrosion, scaling, biological growth, and mechanical wear are enemies that erode performance over time.

A lack of proper cleaning, poor water treatment, ignored vibration issues, and neglected mechanical components all accelerate deterioration. Left unchecked, small issues compound into major repairs or replacements—costly both in terms of money and downtime.

Preventive care isn’t about a single action—it’s a mindset and a system. It involves routine checks, cleaning, water treatment, and mechanical inspections on a scheduled basis.

Preventive maintenance (PM) consists of scheduled, proactive measures designed to keep a system functioning at its best. In cooling towers, that means regularly inspecting and servicing all components before they fail.

Reactive repairs are “fix it when it breaks” responses. In contrast, preventive care anticipates problems and addresses them early, often before the system even shows symptoms.

Some tasks should be performed frequently—think daily or weekly—to ensure the tower is operating smoothly.

A quick visual walk-around can reveal loose bolts, unusual noise, rust spots, or pooled water. These are small clues that something may be amiss. Catching them early is like spotting a tiny crack in your windshield before it becomes a sprawling spiderweb.

Removing debris from the basin, eliminating trash buildup around the tower, and ensuring clear airflow are simple steps but yield big benefits. Neglect these basics, and you’re inviting performance problems.

Going deeper each month helps maintain performance. These inspections usually involve mechanical components and water quality checks.

Inspect fan blades for alignment, check motor mounts for vibration, and ensure belts or couplings are in good shape. A slight imbalance in a fan blade can turn into premature bearing wear if ignored.

Water chemistry is arguably the lifeblood of cooling tower health. pH balance, conductivity, hardness, and biological control must be monitored. Poor water quality not only reduces efficiency but also accelerates corrosion and scaling—two major causes of premature equipment failure.

Seasonal shifts demand changes in care routines. Summer and winter pose different challenges.

In colder climates, water left in the system can freeze, damaging components and piping. Winterization may include draining low points, installing freeze protection systems, and insulating vulnerable areas.

In summer, cooling loads peak. Clean fill media, calibrated water treatment systems, and reliable pumps are essential for peak performance without strain. Think of it like tuning your car before a long road trip.

Water is the medium your tower operates through, and if it’s contaminated, everything else suffers.

Scale acts like a blanket on your heat transfer surfaces, reducing efficiency. Corrosion weakens metal, and fouling clogs flow paths. Effective water treatment minimizes these issues, preserving efficiency and extending lifespan.

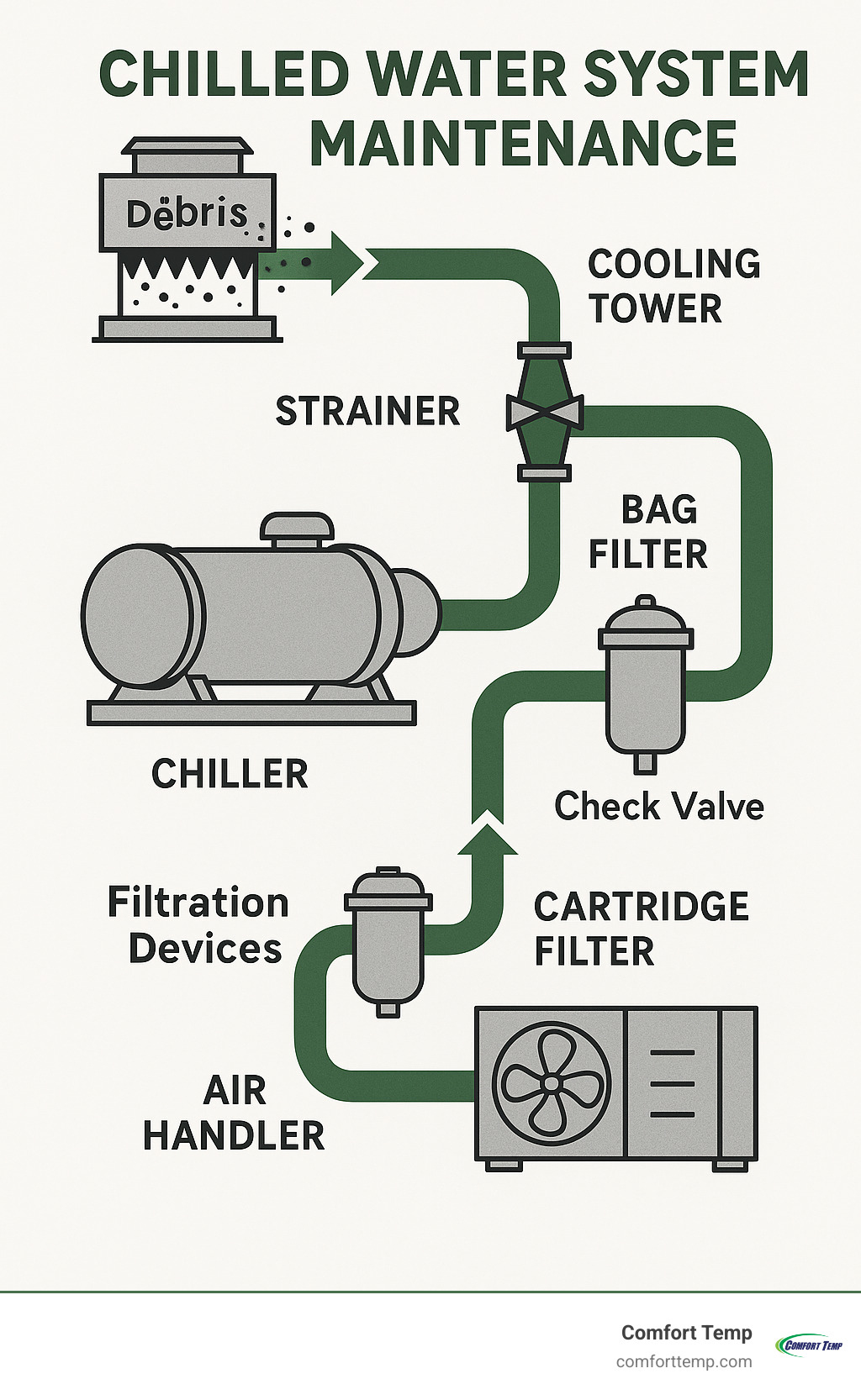

A good filtration system traps debris before it circulates through the tower. Periodic filter cleaning ensures consistent performance and protects critical parts like nozzles and pumps.

Beyond water, the mechanical heart of your tower needs regular attention.

Lubricate bearings, check alignment, and listen for unusual noise. These simple actions prevent bigger failures. A dry bearing or misaligned motor might seem minor at first, but left untreated, it can lead to catastrophic breakdowns.

Fill media enhances heat transfer, and drift eliminators reduce water loss. Both should be inspected and cleaned regularly to maintain efficiency. Replacing aging or damaged media is a small price to pay compared to the energy cost of degraded performance.

Modern preventive care isn’t just about routine tasks; it’s about data. Smart sensors deliver real-time insights into performance and health.

Temperature, vibration, water quality, and flow sensors can alert you to anomalies instantly—before they become problems.

Gone are the days of fixed schedules only. Predictive maintenance uses historical and real-time data to forecast failures before they happen. It’s like having a crystal ball for equipment health—very cool and very useful.

A checklist is only as good as the schedule behind it.

Structure your preventive care around daily, weekly, monthly, and seasonal checklists. Assign responsibilities and ensure tasks are completed on time.

Detailed logs of inspections, repairs, and replacements create a historical record. These records help identify patterns and optimize future maintenance. Think of it as your tower’s medical history—critical for good health decisions.

The benefits extend far beyond equipment health.

Preventive maintenance reduces the likelihood of major repairs, extends equipment life, and improves operational efficiency—all of which lower total lifecycle costs.

Scheduled care means fewer surprises. Downtime becomes predictable (and planned), not sudden and catastrophic. That’s huge for facilities where uptime equals productivity.

While many preventive tasks can be handled in-house, partnering with a professional service provider brings expertise and peace of mind.

Experienced technicians spot issues that might slip past routine checks. They bring specialized tools, industry best practices, and often faster resolution.

Mach Cooling (https://www.machcooling.com/) designs cooling towers and service programs with longevity in mind. Their preventive care solutions include customized maintenance plans, advanced water treatment expertise, and access to replacement parts optimized for long-term performance. With Mach Cooling’s support, facilities experience fewer breakdowns, improved efficiency, and extended equipment life.

Extending a cooling tower’s lifespan isn’t magic—it’s maintenance science combined with practical care. By adopting a comprehensive preventive care strategy, you keep your system running efficiently, reduce costs, and avoid the stress of unexpected failures. Whether it’s routine daily checks or smart, sensor-based predictive monitoring, preventive maintenance is the cornerstone of reliable cooling tower operation.

With the right approach and a trusted partner like Mach Cooling, you’re not just maintaining equipment—you’re investing in performance, longevity, and peace of mind.