We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-05 Origin: Site

If you strip a cooling tower down to its core purpose, everything comes back to one simple phenomenon: evaporation. Fans, motors, fill, and structure all exist to support this single process. Without efficient evaporation, a cooling tower is just a tall box moving warm water around.

Understanding how cooling tower evaporation works—and how it affects performance—is essential for anyone serious about system efficiency, operating cost control, and long-term reliability.

Cooling towers don’t magically make heat disappear. Instead, they rely on evaporation to carry heat away from circulating water. When evaporation is optimized, cooling performance improves naturally. When it’s not, energy use rises, water consumption increases, and operators start chasing problems that never seem to go away.

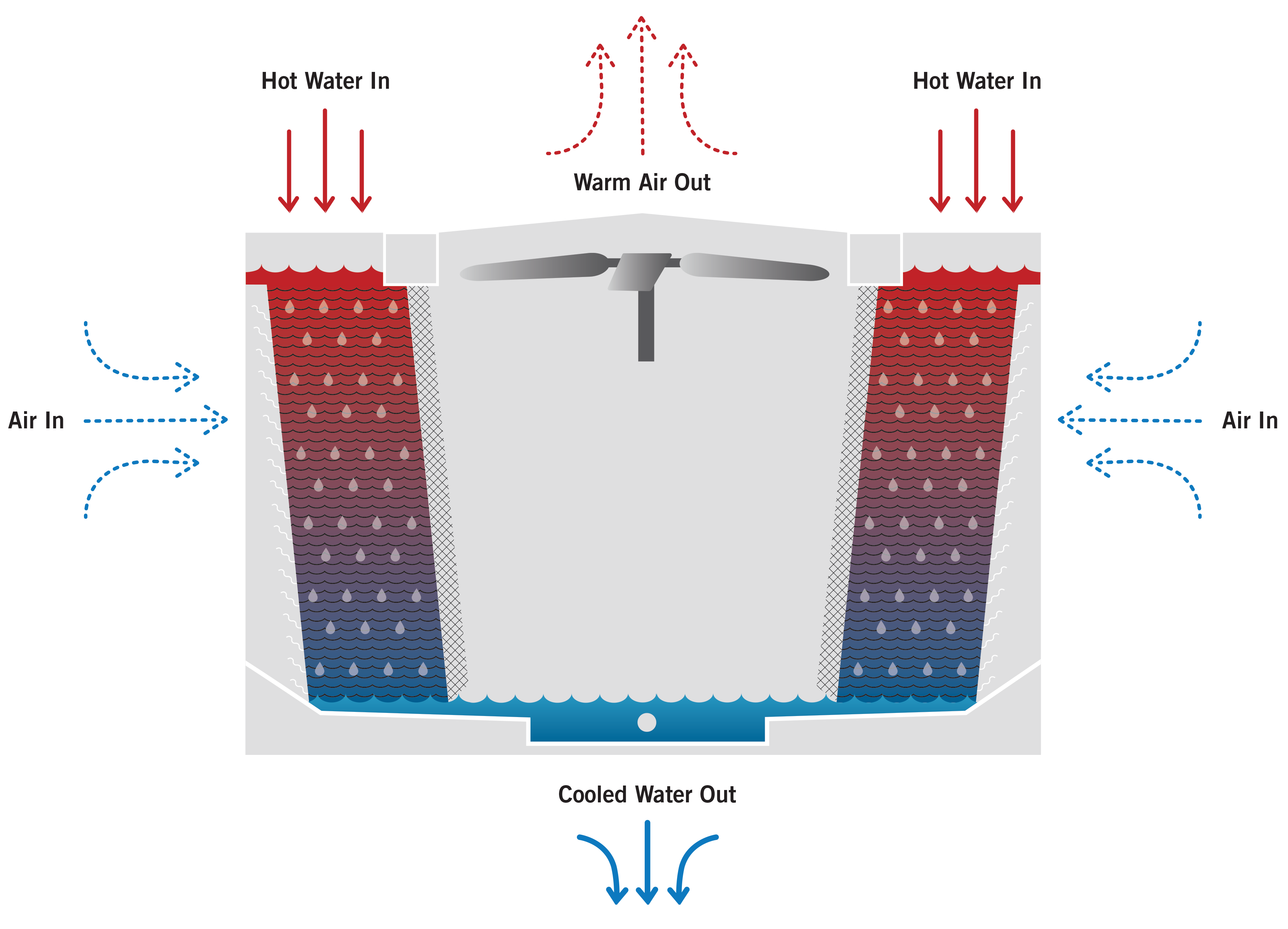

Cooling tower evaporation is the process where a small portion of circulating water changes from liquid to vapor, removing heat from the remaining water.

Evaporation occurs when water molecules absorb enough energy to break free into the air, carrying latent heat with them.

Sensible cooling lowers temperature slightly. Evaporation removes massive amounts of heat in one step, making it the dominant cooling mechanism.

Evaporative cooling is simple physics—but powerful.

When water evaporates, it absorbs latent heat. This heat removal is what drives cooling tower performance.

Lower humidity and higher temperature differences increase evaporation potential.

Evaporation doesn’t happen by accident—it’s engineered.

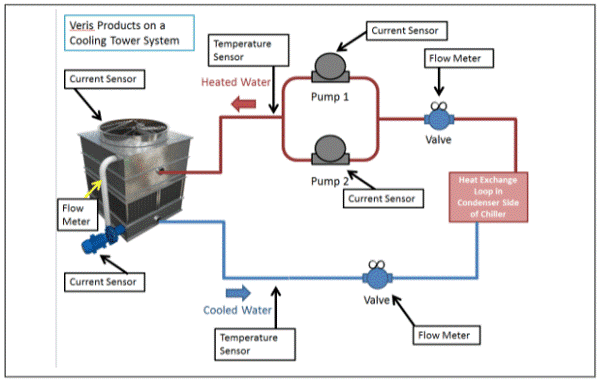

Air moves through falling water, creating maximum surface exposure for evaporation.

Fill media spreads water into thin films or droplets, dramatically increasing evaporation area.

Tower design directly influences evaporation behavior.

Air and water move in opposite directions, offering excellent evaporation efficiency.

Air flows horizontally across falling water, providing stable operation and easy maintenance.

Evaporation performance depends on multiple variables.

Wet-bulb temperature sets the theoretical limit of cooling.

Insufficient or uneven airflow limits evaporation.

Too much water reduces residence time; too little reduces contact.

Evaporation is responsible for most heat rejection in cooling towers.

Over 70% of heat removal typically comes from evaporation rather than temperature drop alone.

Evaporation is beneficial—but it also means water loss.

Evaporation is vapor loss; drift is liquid water carried away by airflow.

Blowdown controls dissolved solids, while evaporation directly removes water.

Evaporation rate can be estimated using heat load, temperature range, and system flow. Accurate calculation helps balance performance and water use.

Efficient evaporation reduces fan runtime, lowers pump demand, and decreases chiller load—directly improving energy efficiency.

The goal isn’t maximum evaporation—it’s optimal evaporation. Smart design balances cooling performance with water conservation.

Better evaporation starts with better design and maintenance.

High-performance fill maximizes surface area without excessive pressure drop.

Even water coverage ensures every part of the fill contributes to evaporation.

Fans, louvers, and tower geometry guide air where it’s most effective.

Evaporation issues often hide in plain sight.

Caused by fouled fill, poor airflow, or uneven water distribution.

Often linked to overdesign or poor operating control.

Evaporation performance is largely determined before the tower is ever installed.

As a professional cooling tower manufacturer, Mach Cooling designs systems that optimize air–water contact, fill efficiency, and airflow balance. These features help customers achieve high cooling performance while controlling water and energy consumption. Learn more at https://www.machcooling.com/.

A manufacturing plant upgraded its fill and corrected airflow distribution. Evaporation efficiency improved, cooling capacity increased, and fan energy consumption dropped—without increasing water usage.

Cooling tower evaporation is not just a design feature—it’s the foundation of performance. When evaporation works efficiently, everything else falls into place: lower energy use, stable operation, and predictable water consumption.

By choosing well-designed systems from experienced manufacturers like Mach Cooling and maintaining optimal operating conditions, facilities can unlock the full potential of evaporative cooling for years to come.