We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-18 Origin: Site

In modern power generation, thermal energy conversion processes produce enormous amounts of waste heat that must be safely and efficiently removed. One of the most effective solutions is the installation of a water cooling tower — an engineered structure that rejects heat to the atmosphere by cooling circulating water used in power plant systems. Without cooling towers, plants would overheat, lose efficiency, and potentially face environmental compliance issues.

This article explains why cooling towers are required in power plants, how they work, what key cooling tower water requirements are essential, and introduces top-quality solutions from the professional manufacturer Mach Cooling (https://www.machcooling.com/) — a renowned water cooling tower system provider.

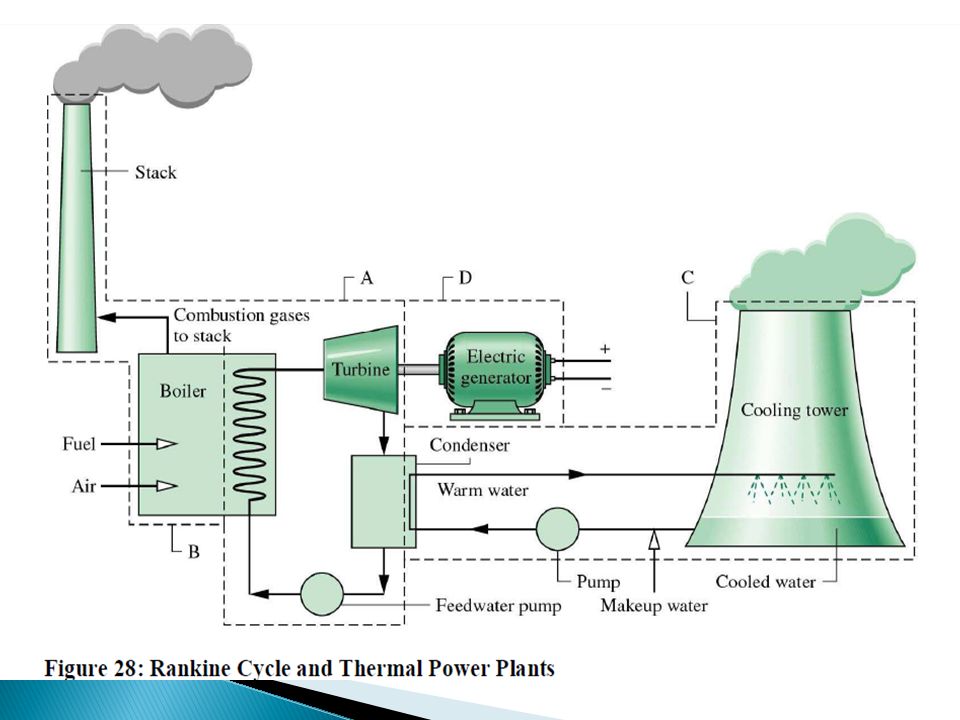

Power plants — especially thermal and nuclear plants — generate electricity by heating water into steam and driving turbines. After steam passes through turbines, it must be condensed back into liquid so the cycle can continue. This condensation process rejects the heat initially absorbed in boilers. Without an external cooling mechanism, that heat would accumulate, damaging equipment and reducing efficiency.

Some plants near large water bodies use once-through cooling where water is drawn, used once to absorb heat, and then discharged back. However:

It requires an enormous water supply.

It risks thermal pollution — high-temperature discharge harms aquatic ecosystems.

Regulations increasingly limit temperature and volume of discharge.

Because of these disadvantages, most inland power plants adopt recirculating cooling systems using cooling towers.

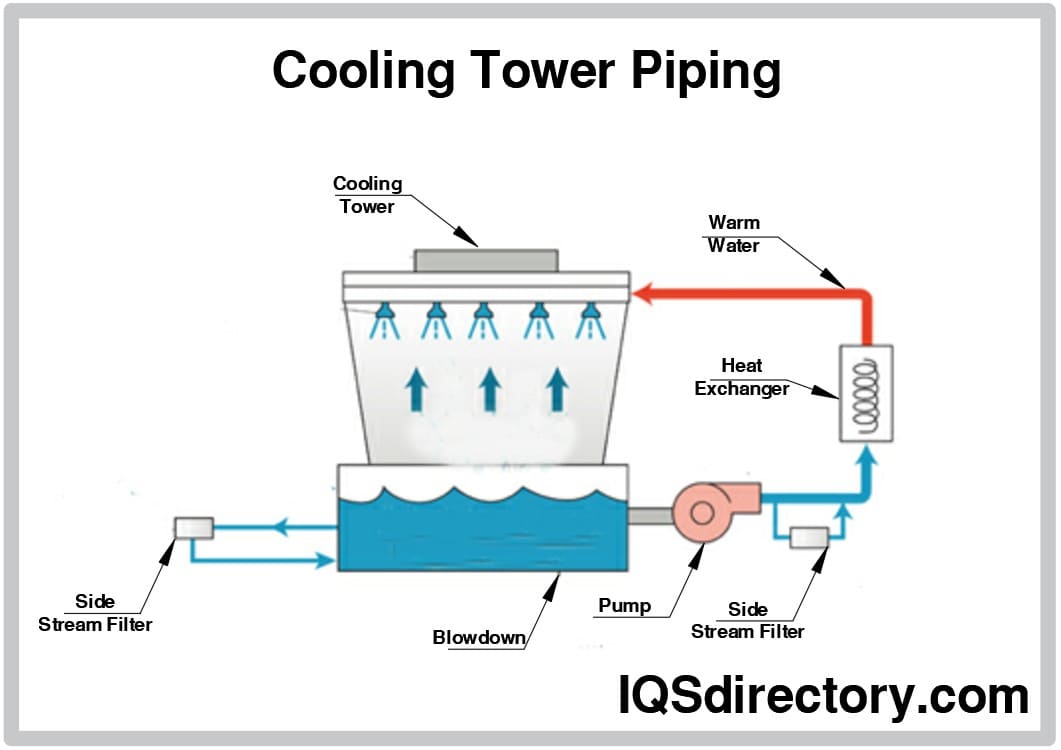

A cooling tower water system is part of a recirculating cooling loop. It works by:

Receiving hot water from condensers or heat exchangers.

Distributing water over fill media where it forms thin films or droplets.

Drawing air through the water, causing evaporation and heat removal.

Collecting cooled water in the basin and returning it to the cycle.

The key to cooling is evaporative heat transfer — water loses heat as a fraction of it evaporates into the air.

Water distribution system — sprays hot water evenly for maximum surface contact.

Fill media — increases water surface area for effective heat exchange.

Fans / air inlets — drive airflow to enhance evaporation.

Drift eliminators — reduce water loss in air stream.

Basin and pumps — collect and circulate water back to the plant.

Power plants generate high volumes of heat. Cooling towers allow this heat to be dissipated into the atmosphere rather than into local water bodies, ensuring equipment stays within safe operating temperatures and maintaining optimal performance.

A cooling tower water management strategy is critical. Instead of once-through water discharge, recirculating systems reuse most cooling water, requiring only makeup water to replace evaporation and blowdown losses. This dramatically reduces fresh water demand.

By reducing thermal pollution and minimizing heated water discharge, cooling towers help power plants meet strict environmental regulations.

Lower condenser temperatures increase the thermodynamic efficiency of steam cycles, yielding higher electrical output from the same fuel input. Effective cooling means more efficient power generation overall.

An efficient cooling tower must be designed with precise water performance criteria in mind. Below is a summary of key metrics that power plant engineers must consider:

The flow rate — volume of water circulated per time — must match the heat rejection capacity of the plant. Larger plants require massive flow rates to maintain acceptable cooling levels.

Example Table: Typical Cooling Water Flow Requirements

| Plant Size | Heat Rejection Load | Approx. Water Flow Rate |

|---|---|---|

| 200 MW | Moderate | 100,000+ GPM |

| 500 MW | Large | 200,000+ GPM |

| 1000 MW | Very Large | 300,000+ GPM |

(Values are representative; actual requirements vary by design and climate.)

Cooling towers circulate water that must be clean, treated, and consistent:

Make-up water supply replaces losses from evaporation and blowdown.

Water usage efficiency depends on evaporation rate, drift control, and blowdown management.

Designing for efficient cooling tower water supply and controlled water usage saves operating costs and conserves water.

Water chemistry control is vital. Hardness, scale, corrosion, and biological growth can reduce performance and increase maintenance costs. Proper cooling tower water management includes filtration, chemical treatment, and blowdown control to maintain optimal thermal transfer.

Power plants may use several configurations depending on size and climate:

Open recirculating water cooling towers — common, effective, and cost-efficient.

Closed-circuit towers — isolate the process water from air contact for sensitive equipment.

Hybrid systems — combine features for specific water or environmental constraints.

Not all facilities are large power plants. Smaller plants, pilot stations, or auxiliary systems might use compact small water cooling towers. These offer:

Lower water flow and footprint

Efficient cooling for smaller loads

Scalable solutions from trusted manufacturers like Mach Cooling

MachCooling is a professional cooling tower manufacturer offering tailored water cooling tower systems for industrial and power generation applications:

Diverse product range: open circuit, closed circuit, counter flow, cross flow models.

Customized solutions: engineered for specific cooling tower water flow rate, temperature ranges, and water quality conditions.

Quality & durability: FRP (fiberglass) and other corrosion-resistant materials.

Support and service: engineering, installation guidance, and technical support for long-lasting systems.

Whether for a large power plant or a small water cooling tower application, MachCooling delivers reliable, efficient solutions.

Cooling towers are indispensable in modern power plant operations. They:

Enable efficient heat rejection

Support water conservation

Ensure environmental compliance

Maximize plant performance

By understanding cooling tower water requirements, flow rates, and system design, engineers can optimize plant cooling operations. Trusted manufacturers like MachCooling play a vital role by providing tailored water cooling tower systems that meet demanding industrial needs.

Explore their solutions at https://www.machcooling.com/ to find the right cooling tower for your power plant project today.