We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-31 Origin: Site

In the era of environmental consciousness, sustainability in industrial systems isn’t optional—it’s essential. Cooling towers, a backbone of industrial and commercial operations, play a massive role in water and energy consumption. One of the most overlooked yet crucial components for improving efficiency and sustainability is the drift eliminator.

Companies like Mach Cooling are leading the way by designing towers that combine high efficiency, sustainability, and low maintenance with advanced drift eliminator technology.

Sustainable cooling towers are not just a trend—they’re a necessity. Industries are under pressure to reduce water usage, cut energy consumption, and comply with environmental regulations. Drift eliminators play a vital role in this equation by reducing water loss and ensuring optimal performance.

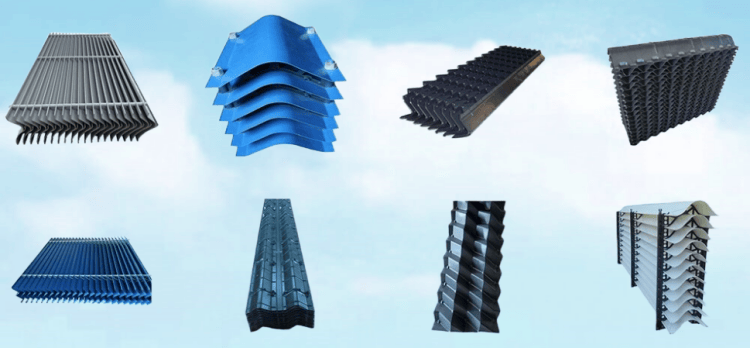

A drift eliminator is a mechanical device installed in cooling towers to capture water droplets that would otherwise escape with the airflow. This prevents water waste, improves efficiency, and protects the surrounding environment.

Minimize water drift into the atmosphere

Enhance tower efficiency by maintaining water balance

Reduce water treatment costs by conserving clean water

Help meet regulatory standards for environmental compliance

In a cooling tower, even small water losses add up. Drift eliminators capture water droplets and redirect them back into the system, conserving thousands of gallons over a year.

Regulatory bodies often set strict limits on water drift to prevent chemical or mineral contamination in the surrounding environment. Efficient drift eliminators make compliance simple and reliable.

By keeping more water in circulation, towers maintain optimal heat transfer, reducing energy consumption and lowering operational costs.

Lightweight, durable, and cost-effective

Resistant to corrosion and chemical attack

Ideal for most industrial applications

Higher temperature tolerance

Excellent chemical resistance

Suitable for specialized industrial processes

Angled, louvered, or chevron designs maximize droplet capture

Reduce both water drift and maintenance frequency

Improve overall cooling tower sustainability

Water droplets rise with the airflow. Drift eliminators redirect these droplets back into the basin using angled louvers or barriers, effectively reducing water loss.

Properly designed drift eliminators work in tandem with fill media and fan airflow, ensuring maximum heat transfer while minimizing water escape.

Install at the exit air path of the tower

Ensure no gaps between sections

Follow manufacturer specifications for airflow and orientation

Inspect quarterly for debris buildup

Clean with mild water pressure or chemical solutions if necessary

Check for cracks or warping that could reduce efficiency

Typically every 5–10 years, depending on water quality and chemical exposure

Replace damaged or warped sections immediately to maintain efficiency

By conserving water and maintaining proper flow, drift eliminators help the tower operate at peak thermal efficiency.

Less water loss means fewer chemicals are needed for water treatment, lowering operational costs and environmental impact.

Well-maintained drift eliminators reduce maintenance interruptions, helping facilities operate continuously and efficiently.

A chemical plant upgraded to high-efficiency PVC drift eliminators. Water savings exceeded 25%, energy efficiency improved, and maintenance intervals increased.

Mach Cooling installed drift eliminators in a data center tower. The result: reduced water consumption, quieter operation, and improved heat rejection efficiency.

Mach Cooling provides customized drift eliminator solutions, ensuring each tower is optimized for water conservation, thermal efficiency, and environmental compliance.

From louvered designs to specialized materials, Mach Cooling tailors each solution to facility requirements, maximizing sustainability and minimizing maintenance.

Advanced towers now feature sensors and AI to monitor water drift, predict maintenance, and optimize cooling efficiency in real time.

Next-generation drift eliminators use recycled plastics or composite materials that are durable, lightweight, and environmentally friendly.

Efficient drift eliminators are no longer optional—they’re essential for sustainable cooling towers. They conserve water, improve thermal performance, lower costs, and ensure regulatory compliance.

By working with experts like Mach Cooling, facilities can implement high-efficiency, sustainable drift eliminator solutions that deliver long-term savings, performance, and environmental benefits.