We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-31 Origin: Site

Cooling towers are essential for industrial operations, HVAC systems, and power plants—but how do you define a cooling tower in terms of heat transfer principles? It’s not just a big box of water and fans; it’s a sophisticated system designed to remove heat efficiently from water and release it into the atmosphere.

Companies like Mach Cooling specialize in creating cooling towers optimized for heat transfer efficiency, energy savings, and long-term reliability.

Understanding the heat transfer principles behind cooling towers helps engineers, plant managers, and facility operators:

Select the right tower for their process

Optimize energy efficiency

Minimize water consumption

Reduce maintenance costs

Without grasping heat transfer, a cooling tower is just an expensive, noisy structure. With it, the tower becomes a highly efficient tool for energy and water management.

A cooling tower is a heat rejection device that removes heat from water used in industrial processes or HVAC systems. Through evaporation and heat exchange, it cools water and recirculates it to the system.

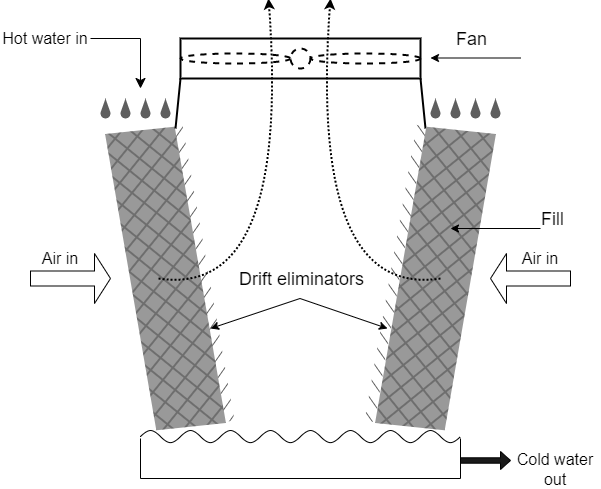

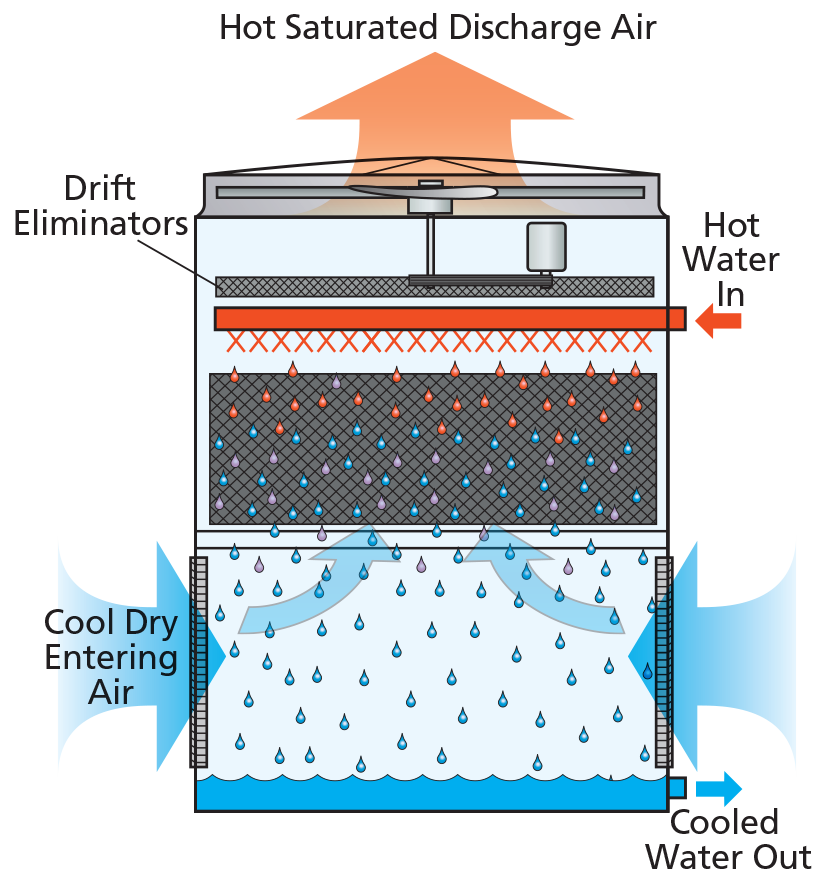

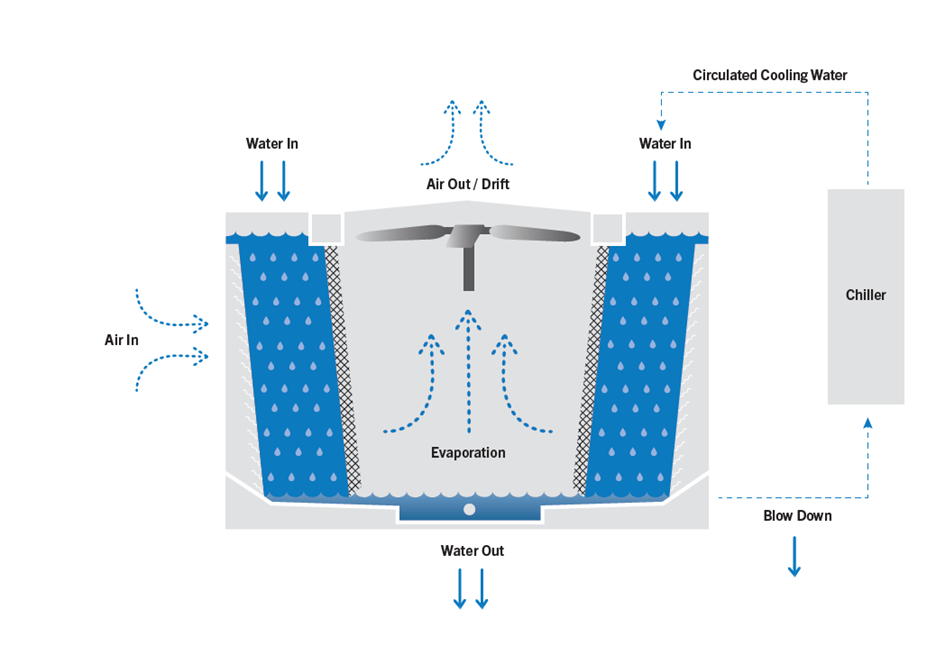

Water Distribution System: Sprays hot water evenly across the fill

Fill Media: Provides surface area for heat exchange

Airflow System: Fans or natural draft move air across water

Basin: Collects cooled water

Drift Eliminators: Reduce water loss through air discharge

Heat moves from the hot water to the air through:

Sensible heat transfer: Change in water temperature

Latent heat transfer: Evaporation of water molecules

This is the foundation for defining the efficiency and performance of a cooling tower.

Evaporation is the most efficient way to remove heat. When a small portion of water evaporates, it carries away a large amount of heat, cooling the remaining water.

The interaction of air and water ensures maximum heat transfer. Crossflow towers move air horizontally, while counterflow towers move air vertically. Both designs impact cooling efficiency.

Air flows horizontally across falling water. Advantages include easy maintenance access and even water distribution. Heat transfer is efficient for medium-to-large industrial systems.

Air moves upward opposite to falling water. Offers higher efficiency per cubic meter, but may require more maintenance due to fill accessibility challenges.

Mechanical draft: Uses fans to force or draw air, giving precise airflow control.

Natural draft: Relies on chimney effect; energy-efficient for large towers but requires taller structures.

Hotter water increases evaporation, while optimal flow ensures even contact with air. Too fast or too slow reduces efficiency.

Heat transfer decreases when ambient air is hotter or more humid. Tower design must account for local climate conditions.

High surface area fills increase contact between water and air, maximizing heat rejection. Material choice impacts durability and maintenance.

Low-noise, high-efficiency fans ensure sufficient airflow without excessive energy consumption.

Range: Difference between hot water entering and cooled water leaving

Approach: Difference between cooled water temperature and wet bulb temperature of ambient air

These metrics define tower efficiency.

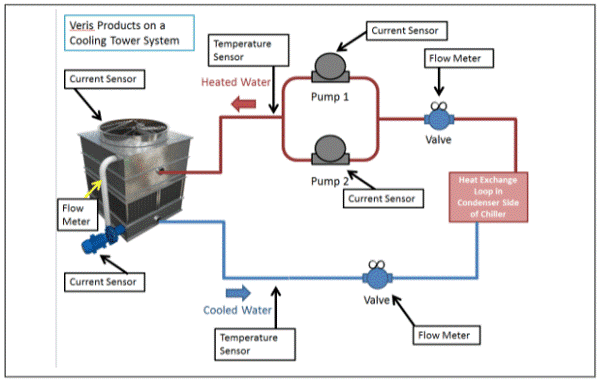

Calculating heat load determines the tower size and airflow needed. The higher the heat load, the larger the tower required.

Reducing water consumption while maintaining cooling efficiency is key. Smart monitoring and water treatment play a vital role.

Regular cleaning of basins, nozzles, and fills prevents scaling and biofilm formation.

Proper chemical treatment reduces corrosion and improves heat transfer.

Automated systems track water quality, vibration, and temperature, enabling predictive maintenance.

A chemical plant upgraded to crossflow towers with optimized fill. Heat transfer improved by 20%, water consumption decreased by 30%.

Mach Cooling installed high-efficiency fans and automated monitoring in a data center. Energy use dropped, while server room temperature remained stable.

Mach Cooling offers tailored solutions that maximize heat transfer efficiency, minimize water use, and reduce maintenance downtime.

From fan design to fill material, each component is optimized to the facility’s needs, ensuring long-term reliability.

AI predicts water demand, heat load, and maintenance needs, improving performance and efficiency.

Low-water towers, recycled water usage, and energy-efficient fans define the future of cooling tower design.

Defining a cooling tower based on heat transfer principles provides a clear framework for design, operation, and efficiency. Understanding airflow, water flow, evaporation, and materials allows engineers to select or upgrade towers effectively.

With Mach Cooling, facilities gain expert solutions that combine heat transfer efficiency, energy savings, and maintenance ease, ensuring reliable and sustainable operation for years to come.