We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

When choosing a cooling tower, one question always comes up first:

Which type of cooling tower is more efficient?

It sounds like a simple question, but the answer isn’t black and white. Cooling tower efficiency depends on many factors—design, operating conditions, climate, and application. Just like cars, what’s “most efficient” for one job may be completely wrong for another.

Let’s break it down in a clear, practical, and human way.

Cooling towers operate continuously in power plants, HVAC systems, and industrial processes. Even small efficiency improvements can result in:

Lower energy consumption

Reduced water usage

Lower operating costs

Longer equipment lifespan

In short, a more efficient cooling tower saves money every hour it runs.

Before comparing types, it’s important to understand what “efficiency” actually means in the cooling tower world.

Thermal efficiency refers to how close the cooled water temperature gets to the ambient wet-bulb temperature. The closer the approach, the more efficient the cooling tower.

True efficiency is not just about temperature. It also includes:

Fan power consumption

Pumping energy

Makeup water demand

Drift and blowdown losses

A cooling tower that cools well but wastes energy or water is not truly efficient.

Cooling towers generally fall into two basic categories.

Open cooling towers expose circulating water directly to air. Heat is removed mainly through evaporation, making these towers highly effective and widely used in industry.

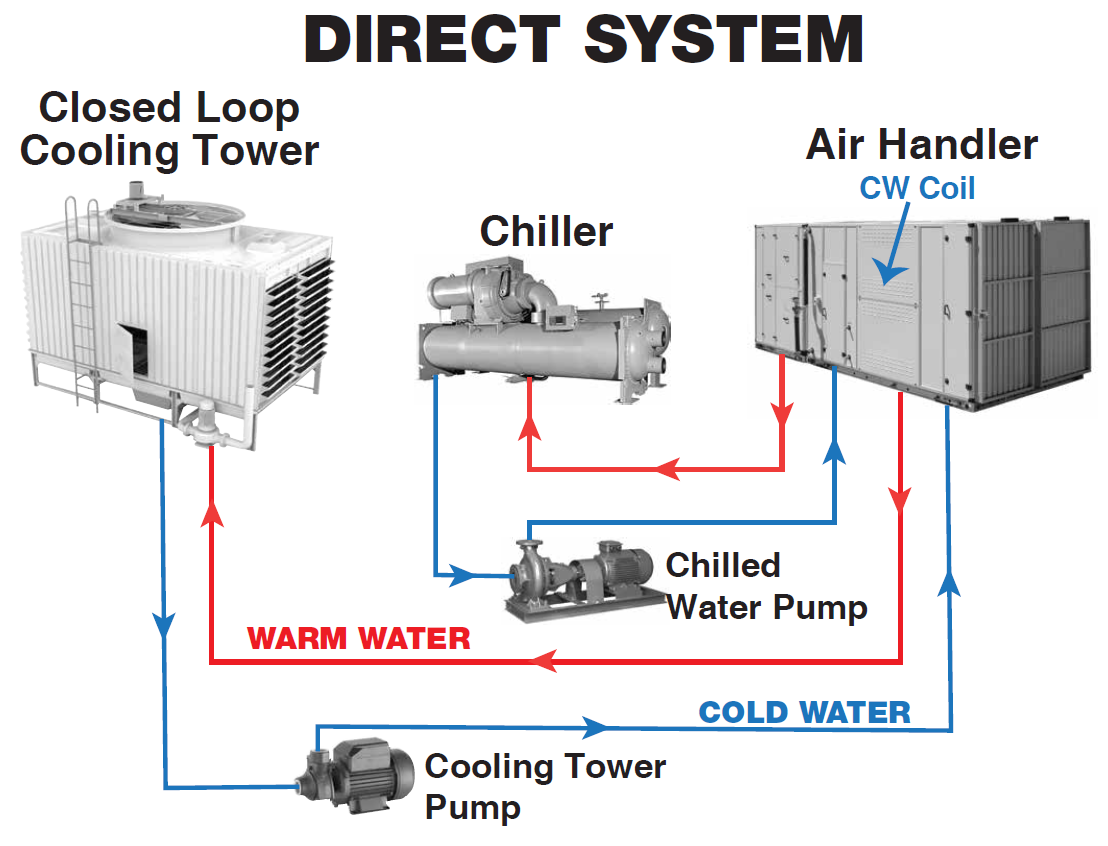

In closed circuit systems, process fluid flows inside coils while external water circulates and evaporates. This protects the process fluid from contamination while still offering good efficiency.

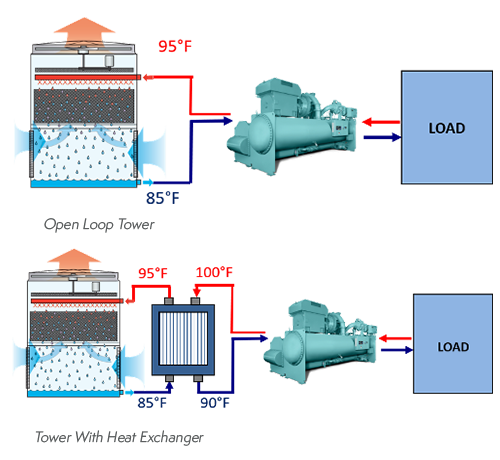

This comparison has a major impact on efficiency.

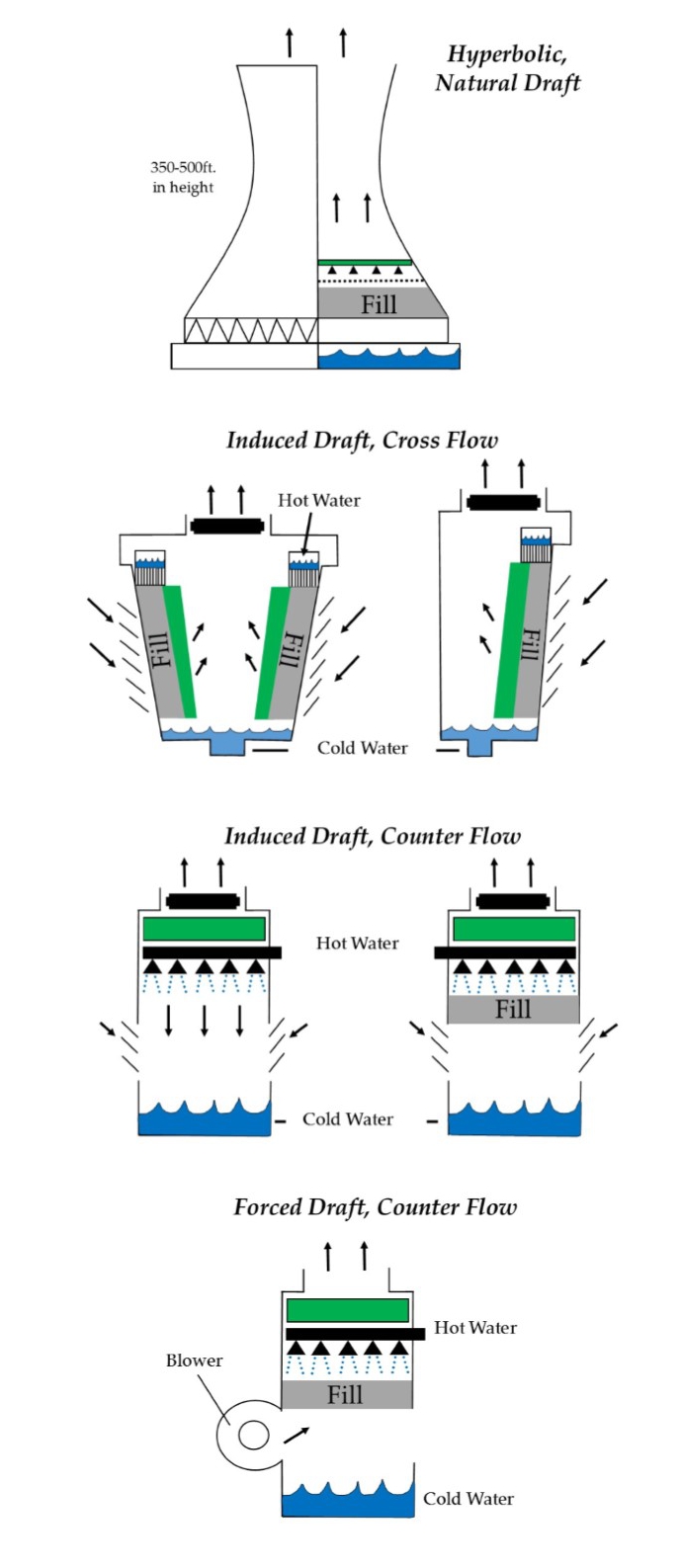

Natural draft cooling towers use a tall hyperbolic structure to create airflow through the stack effect—no fans required.

Efficiency advantages:

Extremely low energy consumption

Excellent performance for massive heat loads

Limitations:

Large size and footprint

High initial construction cost

Natural draft towers are among the most energy-efficient cooling towers for large power plants.

Mechanical draft towers use fans to move air through the system.

Induced draft designs pull air through the tower from the top. They generally offer:

Better airflow distribution

Higher thermal efficiency

Lower recirculation risk

This makes them the most efficient mechanical draft option.

Forced draft towers push air into the system from the bottom. While compact, they typically have:

Higher recirculation

Lower overall efficiency

Airflow direction also affects efficiency.

In crossflow towers, air moves horizontally across falling water.

Lower fan energy

Simple structure

Easy maintenance

Crossflow towers are very energy-efficient for HVAC and light industrial use.

In counterflow towers, air moves upward against falling water.

Higher heat transfer efficiency

Smaller footprint

Better performance in hot climates

Counterflow towers often achieve better thermal efficiency than crossflow designs.

Dry cooling towers use air only, with no evaporation.

Very low water consumption

Lower cooling efficiency

They are suitable where water is scarce but are not the most thermally efficient option.

Wet (evaporative) cooling towers use water evaporation to remove heat.

Highest heat rejection capability

Lower approach temperatures

From a pure thermal standpoint, wet cooling towers are the most efficient.

Efficiency depends heavily on how and where the tower is used.

For large power stations, natural draft wet cooling towers offer unmatched energy efficiency and long-term operating economy.

For commercial and district cooling systems, induced draft crossflow cooling towers provide an excellent balance of efficiency, size, and cost.

In manufacturing and process industries, closed circuit induced draft cooling towers deliver efficient cooling while protecting process fluids.

Even the best tower design can lose efficiency if conditions are poor:

Ambient wet-bulb temperature

Water distribution quality

Fill media performance

Fan and motor efficiency

Maintenance practices

Efficiency is a system outcome, not just a product label.

Cooling tower efficiency depends greatly on:

Aerodynamic airflow design

High-performance fill media

Durable materials

Precision manufacturing

Poor design wastes energy no matter the tower type.

As a professional cooling tower manufacturer, Mach Cooling designs systems with:

Optimized airflow paths

Efficient water distribution

High-quality structural materials

Application-specific engineering

This ensures customers achieve real, measurable efficiency in daily operation.

Learn more at: https://www.machcooling.com/

“Bigger cooling towers are always more efficient”

“More fan power means better cooling”

“Dry cooling towers are always greener”

In reality, efficiency is about matching the right design to the right application.

To choose the most efficient cooling tower, ask:

What is the required heat load?

What is the local climate?

How limited is water availability?

What are the long-term operating costs?

True efficiency should be measured over the entire lifecycle—not just at startup.

So, which type of cooling tower is more efficient?

Natural draft wet cooling towers lead in large power plants

Induced draft wet cooling towers excel in HVAC and industrial applications

Closed circuit towers balance efficiency and cleanliness

The most efficient cooling tower is the one that fits your application, environment, and operating goals—and when engineered by experienced manufacturers like Mach Cooling, it delivers reliable performance, lower costs, and long-term value.