We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-03 Origin: Site

Wooden cooling towers have a long-standing presence in industrial cooling history. Before modern materials like fiberglass-reinforced plastic and corrosion-resistant steel became widely available, wood was one of the most practical construction materials for large cooling towers. Power plants, chemical facilities, refineries, and steel mills around the world relied on wooden cooling towers to dissipate massive amounts of heat.

Even today, many aging industrial sites still operate wooden cooling towers that were built decades ago. While they may still function, the question remains: are wooden cooling towers still a smart choice in today’s industrial environment? To answer that, it is essential to examine both their advantages and disadvantages in detail.

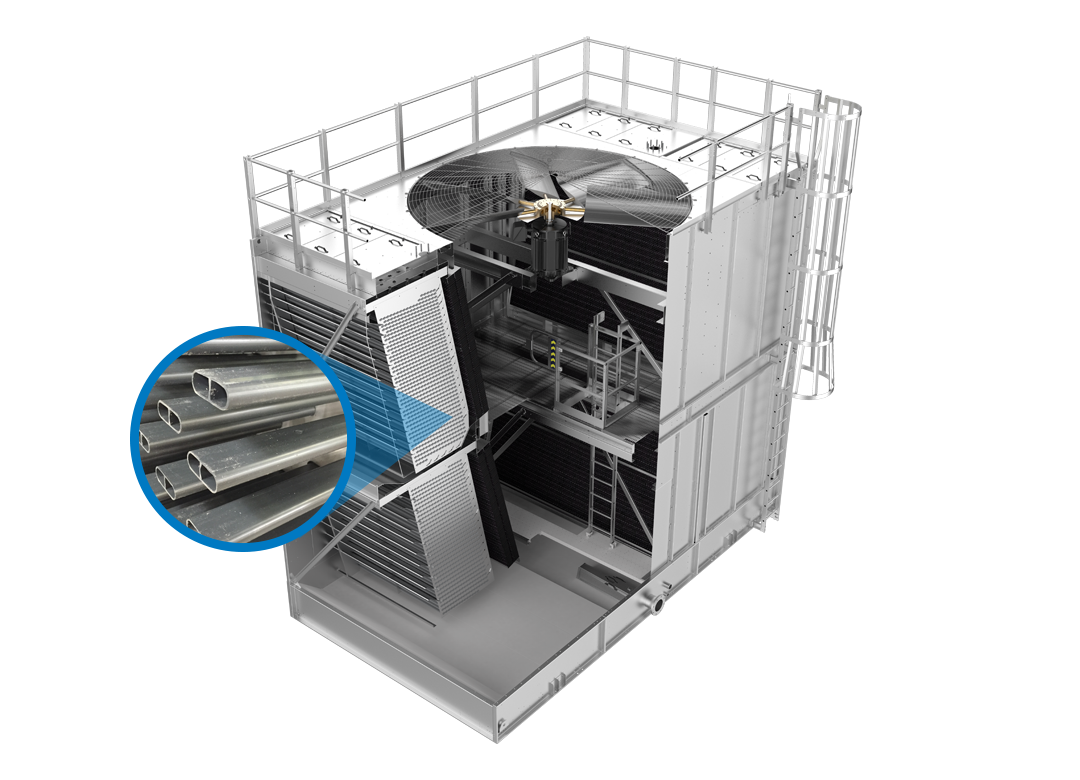

A wooden cooling tower is an evaporative cooling system in which the main structural framework is made from treated wood. The tower removes heat from industrial process water by allowing a small portion of the water to evaporate as air passes through the structure. This evaporation process carries heat away, lowering the temperature of the remaining water.

From an operational standpoint, wooden cooling towers work similarly to modern cooling towers. The key difference lies in the construction material, which significantly affects performance, maintenance, safety, and lifespan.

Wooden cooling towers became popular in the early and mid-20th century, especially for large field-erected installations. At the time, wood was widely available, relatively inexpensive, and easier to work with on-site compared to metal structures.

Redwood, Douglas fir, and other naturally durable woods were commonly used due to their resistance to moisture and decay. For many years, wooden cooling towers were considered reliable and effective. However, as industrial demands increased and safety standards evolved, their limitations became more apparent.

Understanding the structure of a wooden cooling tower helps explain why it offers certain advantages but also presents serious challenges.

A typical wooden cooling tower consists of a wooden support frame, casing, louvers, fill media, water distribution piping, drift eliminators, and mechanical or natural draft airflow systems. All these components work together to maximize the contact between air and water.

The most commonly used woods include redwood and pressure-treated pine. These materials were selected for their natural resistance to moisture, insects, and decay. However, even treated wood degrades over time when exposed to constant heat, water, and chemicals.

At their core, wooden cooling towers rely on evaporative cooling, a simple but effective physical process.

Hot process water is distributed over the fill material inside the tower. As air flows through the structure, a small portion of the water evaporates. This evaporation removes heat from the remaining water, reducing its temperature before it is returned to the industrial process.

Uniform airflow and proper water distribution are critical to cooling efficiency. Uneven flow can reduce performance and accelerate structural wear, especially in wooden components that are sensitive to prolonged moisture exposure.

Despite being considered outdated by modern standards, wooden cooling towers do offer several advantages that once made them attractive.

One of the biggest advantages of wood is that it does not rust. In environments where untreated steel would corrode quickly, wood provided a practical alternative before advanced coatings and alloys became available.

Historically, wood was less expensive than metal or composite materials. For large field-erected cooling towers, this resulted in lower upfront construction costs, making wooden towers appealing for large industrial projects.

Wood naturally provides thermal insulation. This helps reduce heat loss through the structure and can contribute to stable operating conditions in certain applications.

Wooden cooling towers were relatively easy to assemble on-site using basic construction techniques. This was especially beneficial for very large installations where transporting preassembled structures was not practical.

While wooden cooling towers had clear benefits in the past, their disadvantages are the main reason they are no longer widely used.

Fire risk is one of the most serious drawbacks of wooden cooling towers. Even with fire-retardant treatments, wood remains combustible. Fires involving cooling towers can lead to catastrophic damage, long downtime, and serious safety hazards.

Wooden cooling towers require frequent inspection and maintenance. Rot, cracking, biological growth, and structural weakening are constant concerns. Maintenance costs tend to increase significantly as the tower ages.

Compared to modern FRP or steel cooling towers, wooden cooling towers generally have a shorter lifespan. Continuous exposure to water, chemicals, and temperature fluctuations accelerates material degradation.

Preserving wooden structures often requires chemical treatments, which can pose environmental and health risks. Additionally, wooden towers can harbor bacteria and biological growth if not properly maintained.

When compared with modern cooling tower designs, the limitations of wooden cooling towers become even more apparent.

FRP cooling towers offer excellent corrosion resistance, low maintenance requirements, long service life, and superior fire safety. They are lightweight, modular, and designed to meet modern efficiency and safety standards.

Modern steel cooling towers, especially those made with galvanized or stainless steel, provide high structural strength and predictable long-term performance. With proper coatings, corrosion resistance is no longer a major concern.

Wooden cooling towers were once common across several heavy industries.

Thermal power plants relied heavily on large wooden cooling towers to manage enormous heat loads generated during electricity production.

Chemical facilities valued wooden towers for their resistance to certain corrosive environments, at least during the early years of operation.

Steel mills and heavy manufacturing plants often used wooden cooling towers due to their large size and relatively low initial cost.

Maintenance is one of the most critical issues associated with wooden cooling towers.

Constant moisture creates an ideal environment for mold, algae, and bacteria. Over time, these biological factors weaken the wood and reduce structural integrity.

Wooden beams and supports gradually lose strength. Bolted connections loosen, components warp, and small defects can turn into major safety risks if not addressed promptly.

Knowing when to replace a wooden cooling tower is essential for plant safety and efficiency.

Frequent leaks, reduced cooling efficiency, visible structural damage, and rising maintenance costs are strong indicators that replacement should be considered.

While repairing an aging wooden cooling tower may seem cheaper in the short term, long-term costs often exceed the investment required for a modern replacement system.

Today’s cooling tower market offers several superior alternatives.

FRP cooling towers are now the industry standard for many applications due to their durability, fire resistance, low maintenance needs, and long service life.

Steel cooling towers are ideal for demanding industrial environments where mechanical strength and reliability are critical.

Choosing the right manufacturer is just as important as choosing the right cooling tower type.

Manufacturers like Mach Cooling provide modern cooling tower solutions designed to replace aging wooden cooling towers. By focusing on efficiency, safety, durability, and lifecycle cost optimization, Mach Cooling helps industrial users transition from outdated wooden systems to advanced, reliable cooling technologies that meet today’s operational standards.

Wooden cooling towers played an important role in the history of industrial cooling. They offered practical solutions at a time when modern materials were not available. However, their disadvantages—particularly fire risk, high maintenance requirements, and limited lifespan—make them less suitable for today’s industrial needs.

Modern cooling towers provide safer operation, better performance, and lower long-term costs. For most facilities still operating wooden cooling towers, replacement with a modern system is not just an upgrade—it is a strategic investment in safety, efficiency, and reliability.