We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-02-03 Origin: Site

When it comes to industrial cooling, few decisions are as critical as selecting the right type of cooling tower. If your facility needs a 100 ton cooling tower, one key choice you’ll face is single cell vs multi cell configuration. But what does that mean? And why should you care?

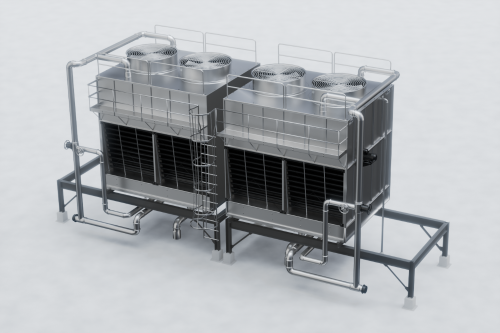

In simple terms, the “cell” refers to an independent cooling unit within the tower. Single cell towers have one large cooling unit, while multi cell towers combine multiple smaller units in one structure. Choosing the right configuration affects performance, cost, maintenance, and even reliability.

A 100 ton cooling tower is an evaporative cooling system designed to reject roughly 100 tons of heat from industrial processes or HVAC systems. It’s commonly used in factories, power plants, and large commercial buildings. Whether it’s a single cell or multi cell configuration, the tower’s main job is to reduce water temperature efficiently.

The number of cells impacts airflow, redundancy, and operational flexibility. Single cell towers are simpler, but multi cell designs can offer backup units if one fails. Understanding these differences is key to maximizing uptime and cost efficiency.

Single cell towers are often the first choice for smaller or medium-sized industrial setups.

A single cell cooling tower features one large unit containing the fan, water distribution system, and fill media. Its simplicity makes it easy to design and install. The compact layout also helps minimize initial costs.

Lower Initial Cost – Fewer components mean less material and simpler construction.

Simpler Maintenance – One fan and one water distribution system make routine checks straightforward.

Compact Footprint – Ideal when space is limited.

Ease of Installation – Single cell towers can often be assembled faster than multi cell alternatives.

No Redundancy – If the fan or pump fails, the entire system goes offline.

Limited Capacity Scaling – Expanding cooling capacity usually requires installing a completely new tower.

Potential Hot Spots – Larger single units may have uneven airflow, reducing efficiency in certain cases.

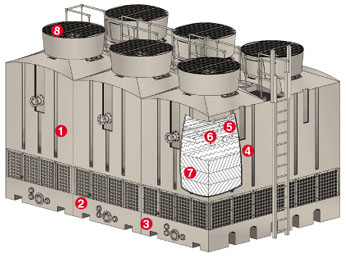

Multi cell towers integrate two or more smaller cooling cells into a single structure. Each cell operates independently but shares a common basin and frame.

Each cell includes its own fan, water distribution system, and fill media. Cells can be turned on or off depending on load requirements, allowing better operational flexibility.

Redundancy – If one cell fails, the others can maintain partial cooling.

Scalable Capacity – You can operate only the number of cells needed for the current load.

Optimized Efficiency – Smaller cells often have more uniform airflow and heat rejection.

Flexibility in Maintenance – Individual cells can be serviced without shutting down the entire tower.

Higher Initial Cost – More fans, motors, and structural components.

More Complex Maintenance – Multiple units require additional inspection and parts.

Larger Footprint – Multi cell towers occupy more space compared to a single cell of equivalent capacity.

Single cell towers perform well for steady, predictable loads. Multi cell towers often outperform single cell designs in fluctuating conditions because you can operate only the cells necessary to meet current cooling demand.

Multi cell towers provide better redundancy. One failed cell doesn’t stop operations, reducing downtime and improving overall reliability.

Single cell towers are simpler to maintain, but multi cell towers allow staggered maintenance schedules. While each cell adds complexity, it also prevents total system shutdown during repairs.

Single cell towers generally cost less upfront due to fewer components and a simpler design. Multi cell towers require more fans, motors, and controls, which increases initial expenses.

Running multiple fans in a multi cell tower may increase energy consumption slightly, but the ability to run only the necessary number of cells can offset this. Single cell towers operate all at once, which is less flexible during partial loads.

When considering maintenance, downtime, and potential expansions, multi cell towers often provide better long-term value, despite higher upfront costs. Single cell towers may save money initially but could incur higher costs if redundancy or scalability is needed.

Facilities with consistent, predictable cooling loads

Limited installation space

Tight initial budget

Facilities requiring high reliability and redundancy

Industrial processes with fluctuating heat loads

Large-scale operations where maintenance flexibility is important

Multi cell towers may produce more noise due to multiple fans, but modern design optimizations can mitigate this. Single cell towers are quieter but may have uneven airflow.

Operating only the required cells in a multi cell tower can reduce energy waste. Single cell towers are less adaptable to partial load conditions.

Professional manufacturers like Mach Cooling (https://www.machcooling.com/) design both single cell and multi cell 100 ton cooling towers with a focus on efficiency, reliability, and safety. They offer tailored solutions, advanced quality control, and after-sales support, helping industrial users get the best performance from their cooling systems.

Choosing between a single cell and multi cell 100 ton cooling tower is not just about cost—it’s about performance, reliability, maintenance, and flexibility.

Single cell towers are ideal for smaller, steady-load applications with limited space and budget.

Multi cell towers shine in large-scale, critical operations where redundancy, scalability, and maintenance flexibility are priorities.

Working with a trusted manufacturer like Mach Cooling ensures your cooling tower meets your specific industrial needs, whether you go single cell or multi cell.