We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

Cooling towers are essential in industrial and HVAC systems, maintaining process temperatures and keeping equipment operating efficiently. But have you ever stopped to think about the valves that control water flow in these systems? Valves might seem small, but they are the unsung heroes of cooling tower operation. They regulate water flow, maintain system pressure, protect equipment, and ensure smooth performance. Without the right valves, even the most advanced cooling tower can suffer from inefficiency or downtime.

Valves perform several critical functions in a cooling tower system:

Control Water Flow: They regulate how much water moves through the system, ensuring optimal heat rejection.

Maintain System Pressure: Valves help balance pressure, protecting pumps and piping from overpressure or low-flow issues.

Ensure Safety and Reliability: Safety and relief valves prevent overpressure situations that could damage equipment.

Valves are essential for controlling water circulation, maintaining operational safety, and ensuring reliability in cooling tower systems. Proper valve operation allows the cooling tower to function efficiently year-round.

Valves adjust the water flow, making sure that each section of the cooling tower receives the proper amount of water. Too much flow can cause turbulence, while too little reduces heat transfer efficiency.

A stable system pressure is crucial for pump performance and pipe integrity. Valves help keep pressures within safe operating limits, preventing equipment damage and operational issues.

Safety valves automatically relieve excess pressure, protecting pumps, pipes, and other critical components. Reliable valve operation reduces unplanned downtime and maintenance costs.

Valves can be categorized by function, actuation method, and material.

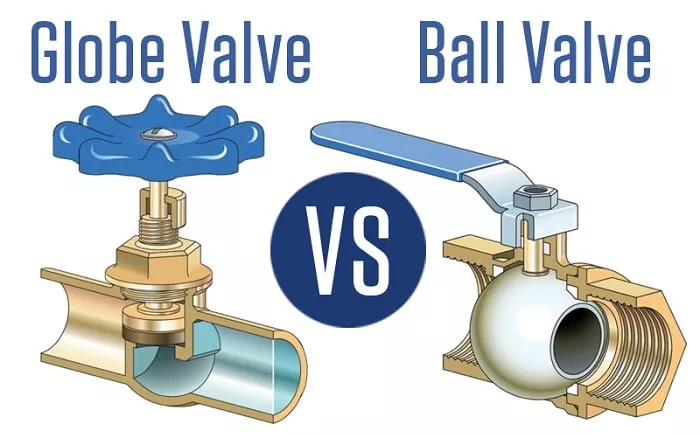

Used to shut off sections of the system for maintenance or repair. Common examples include gate and ball valves.

Regulate flow or pressure for precise system operation, often automated for accuracy.

Prevent backflow, ensuring water moves in the intended direction.

Automatically release water when pressure exceeds safety limits, preventing damage to pumps and piping.

Operated by hand, simple, reliable, and ideal for smaller or low-frequency operations.

Controlled electrically or pneumatically, providing precise and consistent control, especially in automated or large systems.

Highly resistant to corrosion and ideal for aggressive industrial water conditions.

Durable, commonly used in HVAC applications with less aggressive water.

Lightweight and corrosion-resistant, suitable for chemical or high-moisture environments.

Used mainly for isolation, allowing full open or closed positions with minimal flow resistance.

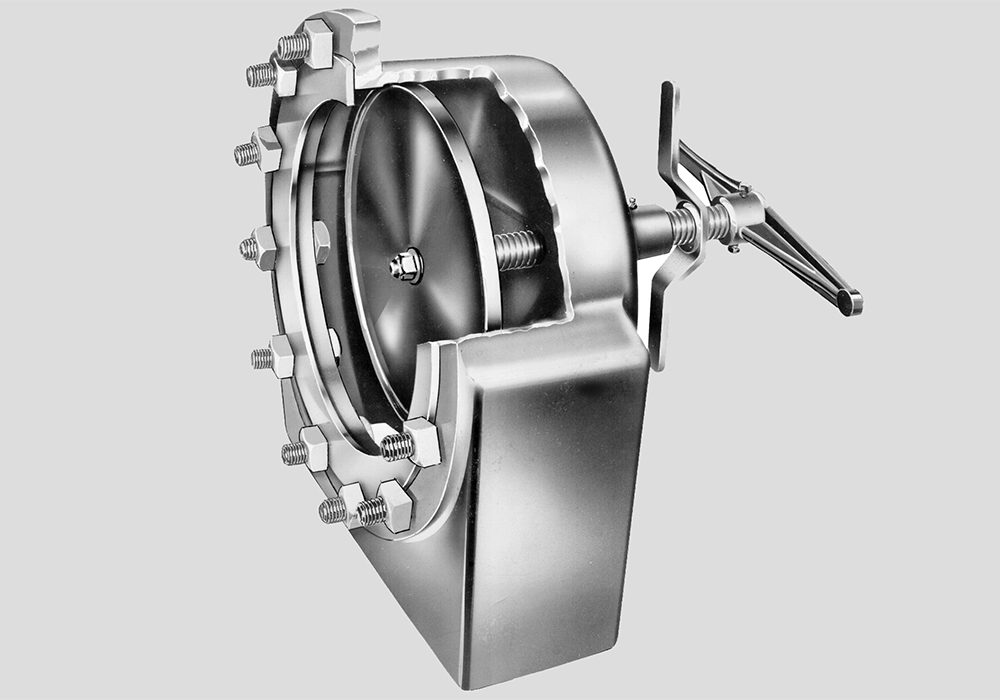

Designed for flow regulation, offering precise control and effective in balancing applications.

Compact, lightweight, suitable for large-diameter piping, and available in manual or motorized versions.

Provide quick on/off operation, reliable sealing, and minimal maintenance.

Prevent backflow, protecting pumps and other critical equipment.

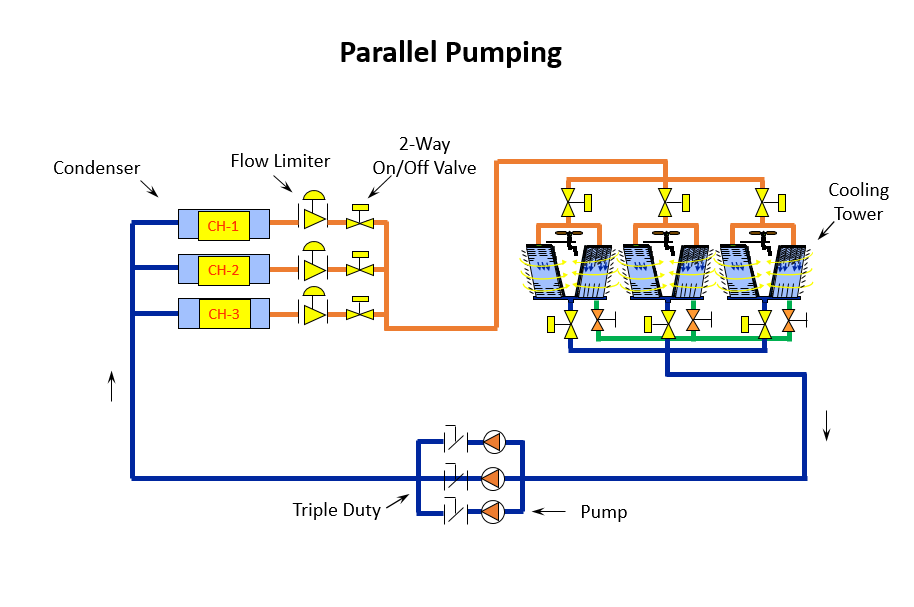

Allow water to be rerouted during maintenance or low-load operation without shutting down the entire system.

Ensure even water distribution across the tower, maximizing heat transfer efficiency.

Prevent reverse flow in multi-cell cooling towers or parallel pump systems.

Choosing the correct valve involves considering several factors:

Select valves that can handle the maximum flow and system pressure to avoid undersized or oversized components.

Consider the water’s chemical composition, temperature, and potential debris. Corrosion-resistant materials extend the valve’s service life.

Valves should be easy to access and maintain. Proper maintenance reduces downtime and operational costs.

Mach Cooling (https://www.machcooling.com/) manufactures valves specifically for cooling tower systems. Features include:

Corrosion-resistant materials

Manual and motorized options

Precision control for optimized system performance

Comprehensive support and maintenance guidance

Ensure clear access for operation and maintenance.

Regularly check for leaks and proper sealing.

Follow manufacturer torque and alignment guidelines for motorized valves.

Keep valves clean of debris and sediment for long-term reliability.

Cooling tower valves are more than simple on/off devices—they are critical control components that directly affect water flow, pressure, efficiency, and system longevity. From gate, globe, butterfly, ball, and check valves to specialized flow control, bypass, and anti-backflow valves, each plays a specific role.

Selecting the right valve, using high-quality materials, and maintaining them properly ensures peak performance and reliability. For dependable, long-lasting cooling tower valves, Mach Cooling (https://www.machcooling.com/) provides solutions designed to keep your systems running efficiently year-round.