We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

Cooling towers operate in open environments, constantly exposed to air, water, and surrounding conditions. While their primary function is to reject heat efficiently, they also face an unavoidable challenge—debris intrusion. This is where cooling tower screens become essential. But exactly what type of debris can cooling tower screens trap, and why is this so important for system performance and longevity?

Let’s break it down in a clear, practical way.

Think of a cooling tower screen as a security checkpoint. Water flows freely, but unwanted materials don’t get a free pass. Without proper screening, debris can enter pumps, clog nozzles, damage heat exchangers, and reduce cooling efficiency—sometimes catastrophically.

Because cooling towers are installed outdoors, they are exposed 24/7 to natural, airborne, and industrial contaminants. Screens act as the first line of defense.

Cooling tower screens are mechanical filtration devices installed at key points such as:

Cold water basins

Makeup water inlets

Pump suction lines

Flume or channel entrances

Their primary role is to trap debris before it enters the circulating water system, ensuring stable flow and protecting downstream equipment.

Cooling tower screens are designed to capture a wide spectrum of debris, ranging from large visible objects to fine biological materials.

Leaves, branches, and twigs are among the most common debris found in cooling towers, especially in facilities surrounded by trees or green areas. During autumn, leaf accumulation can be severe.

If not trapped, these materials can:

Block pump suction

Decompose and form sludge

Promote bacterial growth

Grass clippings, weed fragments, and airborne seeds often enter cooling towers from nearby landscaping. Over time, they collect in basins and restrict water flow.

In dry climates, desert regions, or industrial zones, dust and sand are continuously pulled into cooling towers with intake air. While fine particles may pass through, screens trap larger abrasive debris that would otherwise settle and cause wear.

Flying insects, pollen, and fibrous organic matter are common seasonal contaminants.

These materials accelerate biofouling and increase chemical consumption if not intercepted early.

Plastic bags, packaging film, and synthetic fibers are particularly dangerous. They don’t dissolve and can:

Wrap around pump impellers

Block strainers

Cause sudden pump failure

Cooling tower screens are highly effective at capturing these materials before damage occurs.

Paper scraps and cardboard fragments break down in water, forming soft sludge that clogs piping and spray nozzles. Screens prevent these materials from circulating throughout the system.

Algae growth is common in warm, wet cooling tower environments. When algae detach, screens help trap larger clumps before they spread through the system.

In systems using river water, reclaimed water, or open reservoirs, larvae or small organisms may enter the cooling tower. Screens provide essential biological control at the inlet stage.

Debris types vary throughout the year:

Spring: pollen, seeds, insects

Summer: algae, insects, dust

Autumn: leaves, twigs, organic matter

Winter: wind-blown trash, plastic debris

Choosing the right screen design ensures year-round protection.

By effectively trapping debris, cooling tower screens:

Prevent pump clogging and cavitation

Maintain consistent water flow

Protect spray nozzles and fill

Improve heat transfer efficiency

Reduce unplanned shutdowns

In short, screens protect both performance and capital investment.

Designed for large debris like leaves, branches, and plastic bags. Commonly installed at basin inlets.

Installed near pump suction points to stop medium-sized debris from entering circulation.

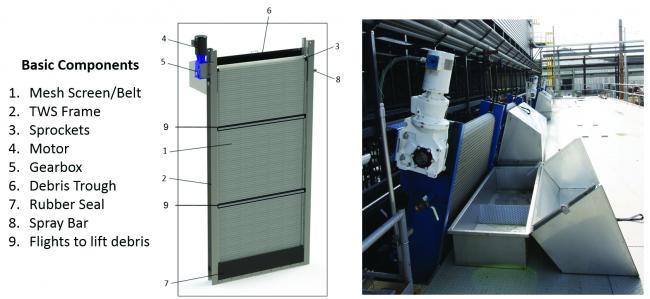

Ideal for large industrial cooling towers, these systems continuously remove debris without manual intervention.

Without proper screening:

Pumps suffer frequent failures

Spray nozzles clog

Cooling efficiency drops

Water treatment costs increase

Maintenance workload rises

Skipping debris control is a short-term saving that leads to long-term losses.

Mach Cooling (https://www.machcooling.com/) designs and manufactures cooling tower screens built for real industrial conditions.

Mach Cooling screen solutions offer:

Durable stainless steel or FRP construction

Optimized mesh sizing for specific debris types

Easy access for inspection and cleaning

Long service life and reliable performance

To keep screens effective:

Inspect regularly, especially during high-debris seasons

Clean accumulated material promptly

Check for corrosion, deformation, or blockage

Routine maintenance ensures consistent protection and long-term efficiency.

So, what type of debris can cooling tower screens trap? The answer includes leaves, twigs, grass, dust, insects, pollen, plastic waste, paper, algae, sludge, and even small aquatic organisms. Each may seem minor alone, but together they can severely impact cooling tower performance.

By selecting high-quality cooling tower screens from trusted manufacturers like Mach Cooling, operators ensure cleaner water, higher efficiency, reduced maintenance costs, and longer equipment life.

In cooling tower systems, effective debris control isn’t optional—it’s essential.