We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

When winter arrives, many operators ask the same critical question: what prevents the water in a cooling tower from freezing? Cooling towers operate outdoors, fully exposed to cold air, wind, snow, and sub-zero temperatures. At first glance, it seems almost inevitable that the water would turn into ice.

Yet in reality, cooling towers operate safely in cold climates all over the world. The reason lies in smart engineering, basic thermal physics, and proper operation. Let’s take a clear, practical look at how cooling towers stay ice-free—even in harsh winter conditions.

Freezing is not just an inconvenience; it can be destructive. Ice formation can damage fill, crack piping, block airflow, and even cause structural failure. Once ice builds up, performance drops quickly and repair costs rise even faster.

That’s why preventing freezing is a core design and operational focus for professional cooling tower manufacturers like Mach Cooling.

Yes, cooling tower water can freeze—but only under specific conditions. Freezing usually occurs when:

Water circulation stops

Heat load is extremely low

Airflow is uncontrolled

The tower is improperly operated or shut down

A properly designed and operated cooling tower rarely freezes during normal operation.

Ice does not appear everywhere at once. It typically begins in:

Splash zones near air inlets

Low-flow or stagnant areas

Idle distribution piping

Basin corners during shutdown

Knowing these risk areas is key to prevention.

When water freezes, it expands. That expansion can:

Break fill packs

Crack basins and pipes

Unbalance fans

Block airflow paths

In short, freezing can turn a cooling tower into a maintenance nightmare.

Cooling towers rely on simple but powerful physics.

Water returning from the process or condenser always carries heat—even in winter. As long as the circulating water temperature remains above freezing, ice cannot form.

Think of it like a moving cup of warm coffee outside on a cold day. It cools gradually, but it doesn’t instantly freeze.

Moving water freezes far more slowly than stagnant water. Continuous circulation keeps water molecules active and prevents ice crystals from forming.

This is why operating towers are far safer than idle ones.

Heat load is one of the strongest natural freeze-protection mechanisms. The more heat the system rejects, the easier it is to keep water temperatures above freezing.

Low-load or no-load conditions are when freezing risk is highest.

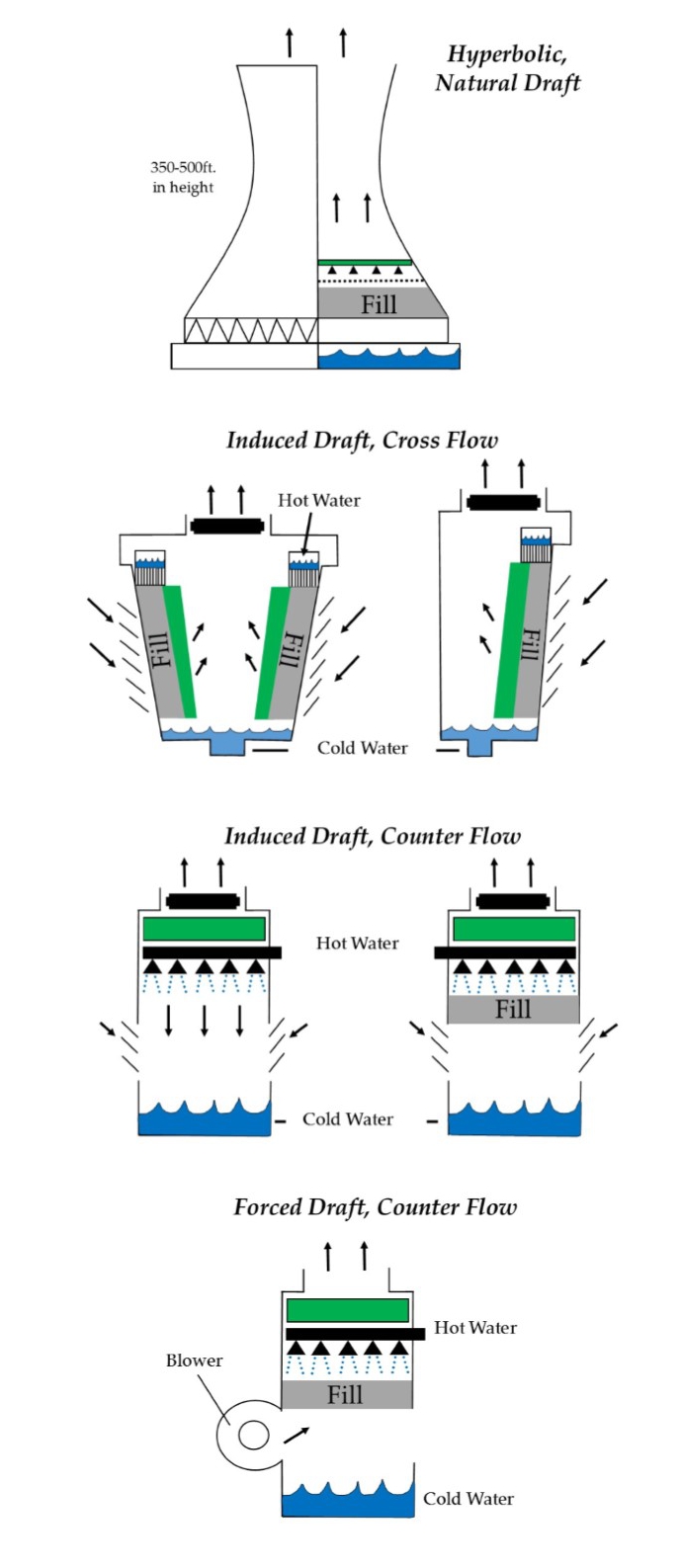

Airflow is a double-edged sword in winter. Too much airflow can overcool the water, but controlled airflow keeps temperatures stable.

In cold climates, fans are rarely run at full speed. Reducing airflow prevents excessive cooling and ice formation.

Variable-frequency drives (VFDs) allow precise fan speed control, making them one of the most effective tools for winter freeze protection.

Maintaining proper water temperature is essential.

Even in winter, chillers, condensers, and industrial processes return warm water to the cooling tower. This heat acts as a natural antifreeze.

The cooling tower basin holds a large volume of water. Large volumes take longer to freeze, especially when circulation continues and heat is constantly added.

Modern cooling towers are engineered with freeze protection in mind.

Electric or steam basin heaters keep water above freezing during low-load or shutdown conditions. They are especially critical in cold climates.

Insulated piping, louvers, and partial enclosures reduce exposure to cold air and wind chill, helping stabilize water temperature.

Water chemistry also plays a small role in freeze prevention.

In closed-loop systems, antifreeze solutions like glycol may be used. However, open cooling towers rarely rely on antifreeze due to evaporation losses, cost, and environmental concerns.

Good operation is just as important as good design.

Gradual startup allows water temperature to rise before full airflow is introduced, reducing freezing risk.

During very low load conditions, operators may:

Shut down individual cells

Use bypass lines

Reduce fan speed

Keep water circulating

❌ Cooling towers freeze whenever temperatures drop below 0°C

❌ Fans must always run at full speed

❌ Antifreeze is mandatory in winter

In reality, control and design matter more than temperature alone.

Manufacturers like Mach Cooling (https://www.machcooling.com/) design cooling towers specifically to handle extreme weather conditions.

Mach Cooling towers feature:

Optimized airflow control

Strong basin and structural design

Compatibility with heaters and VFD systems

Durable materials that withstand freeze–thaw cycles

To keep cooling towers operating safely in winter:

Maintain continuous water circulation

Control fan speed carefully

Monitor basin temperature

Use basin heaters during low load

Follow manufacturer guidelines

A properly managed cooling tower can operate reliably even in extreme cold.

So, what prevents the water in a cooling tower from freezing? The answer is not a single component, but a smart combination of heat load, water movement, airflow control, mechanical design, and proper operation.

With high-quality equipment from manufacturers like Mach Cooling, plus correct winter operating practices, cooling towers can run smoothly through the coldest months—without ice, damage, or downtime.

Freezing isn’t inevitable. With the right design and operation, it’s completely under control.