We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

Cooling towers may not grab attention like turbines or compressors, but they play a critical behind-the-scenes role in industrial and commercial cooling systems. From power plants and factories to large HVAC systems in office buildings, cooling towers are essential for removing unwanted heat and keeping systems running efficiently.

So, what is the real purpose of a cooling tower, and why is it so important? Let’s break it down in a clear, practical, and human way.

At its simplest, a cooling tower is a device that removes heat from water by transferring that heat into the atmosphere. It allows warm water from industrial or HVAC systems to be cooled and reused instead of being wasted.

Think of a cooling tower like a car radiator—except on a much larger scale and using evaporation instead of airflow alone.

Modern equipment generates enormous amounts of heat. If that heat isn’t removed efficiently, systems slow down, energy consumption rises, and failures become unavoidable.

Cooling towers exist to solve one fundamental problem:

Heat must go somewhere.

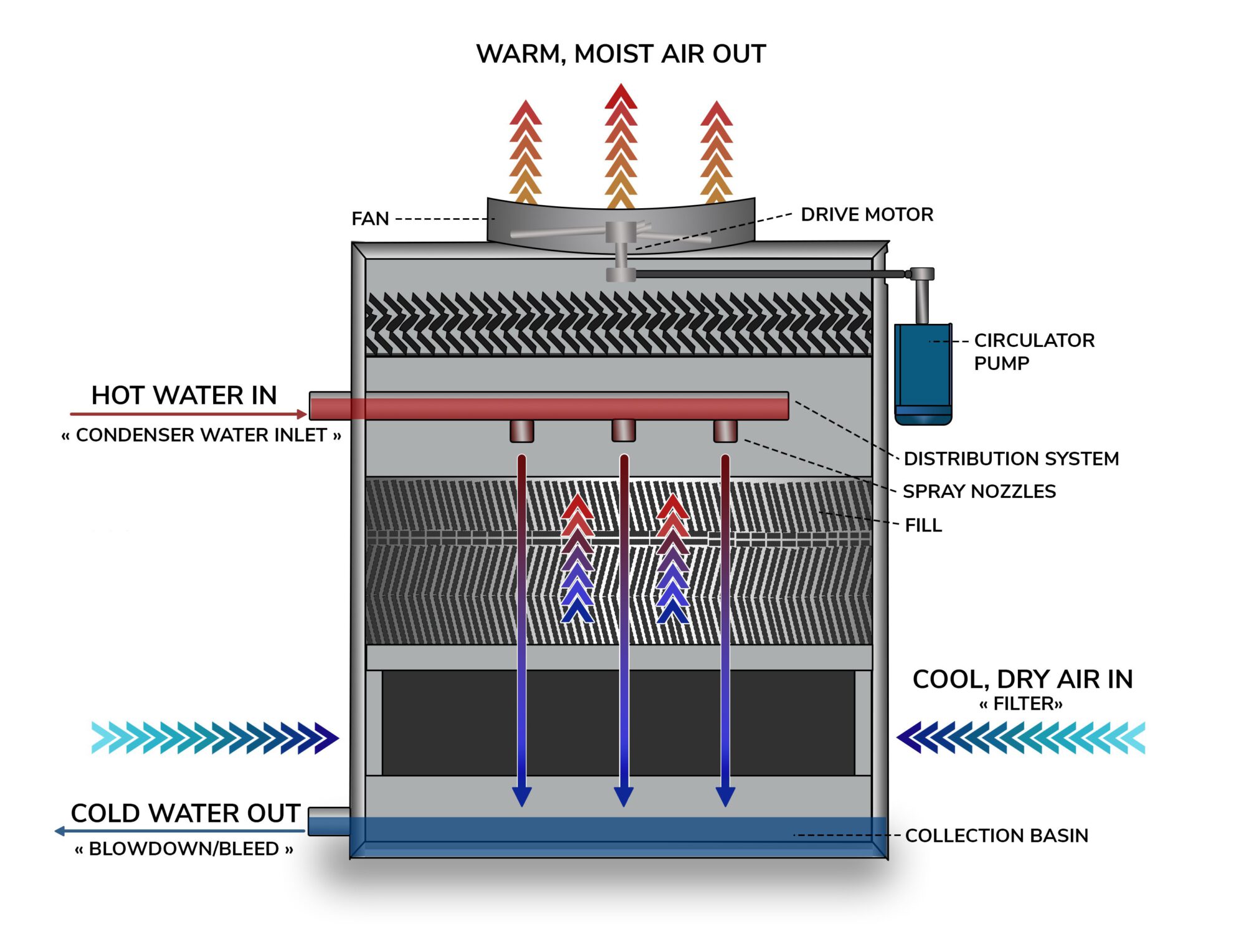

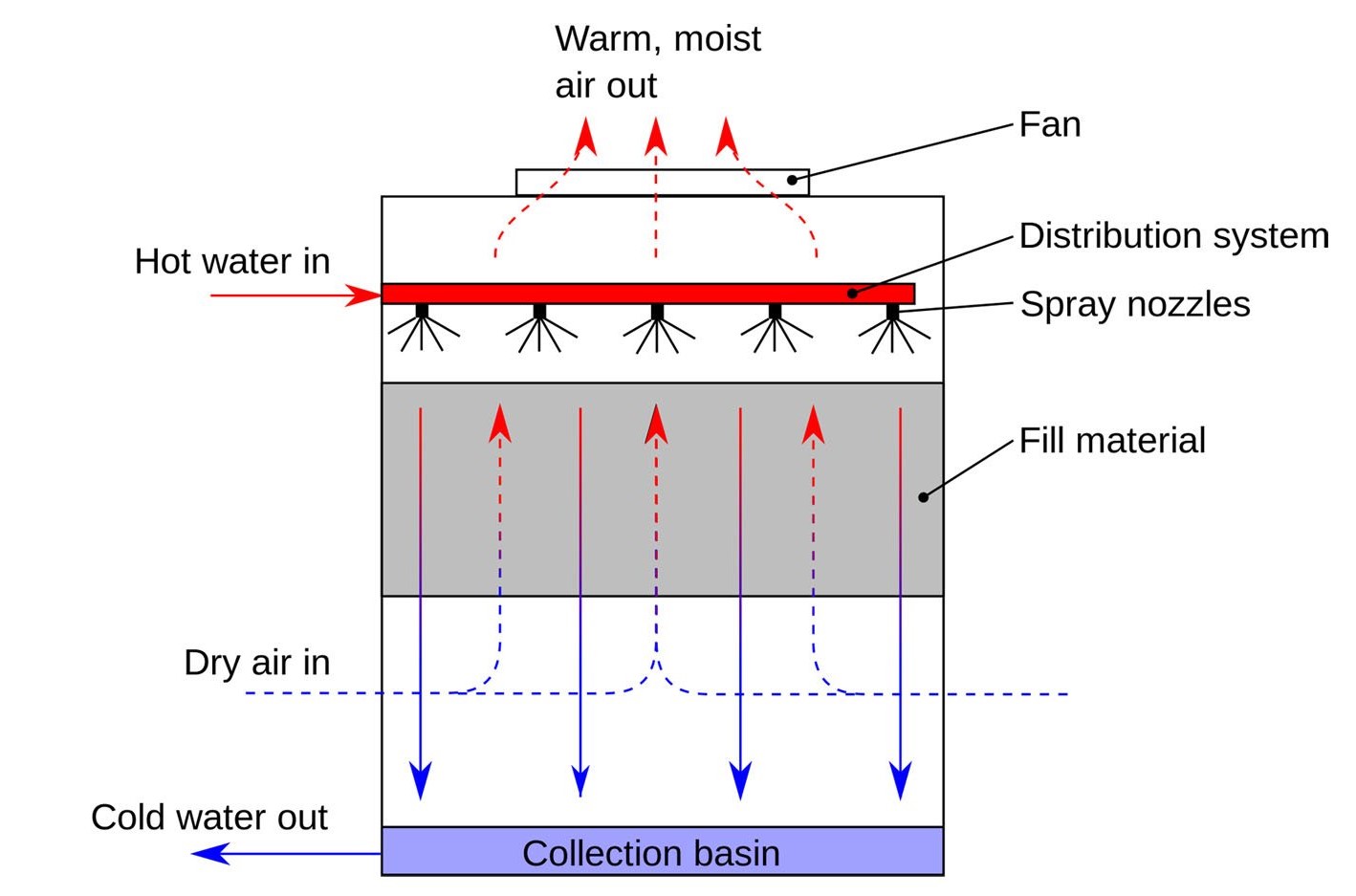

Cooling towers reject heat by bringing hot water into contact with air. A small portion of the water evaporates, carrying heat away and lowering the temperature of the remaining water.

Water is excellent at absorbing heat, but once it becomes too hot, it can no longer cool equipment effectively. Recycling hot water without cooling it is like trying to cool a room with a broken fan—it just doesn’t work.

The primary purpose of a cooling tower is:

➡ To cool hot water so it can be reused safely and efficiently in a continuous system.

This single function supports multiple system goals.

Cooling towers maintain stable operating temperatures, preventing overheating and protecting equipment from thermal damage.

By using natural evaporation instead of energy-intensive refrigeration, cooling towers dramatically reduce power consumption.

Stable temperatures mean fewer shutdowns, less maintenance, and longer equipment life.

Understanding how a cooling tower works makes its purpose even clearer.

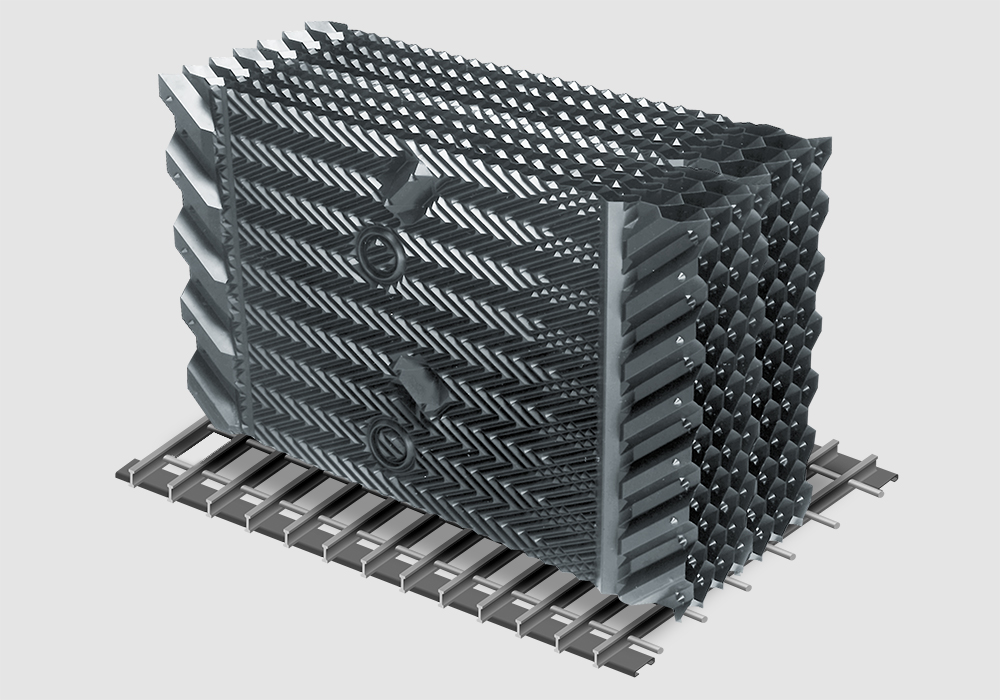

Hot water is distributed over fill material inside the tower. As air passes through, a portion of the water evaporates. This evaporation removes heat from the remaining water, cooling it before it returns to the system.

Sensible heat lowers water temperature directly

Latent heat is removed through evaporation

Cooling towers rely heavily on latent heat, which makes them extremely efficient.

Fans or natural draft airflow maximize air-to-water contact, ensuring efficient heat transfer and consistent cooling performance.

Different cooling applications require different cooling tower designs.

In open cooling towers, water directly contacts air. They are simple, cost-effective, and highly efficient.

Common uses: Power plants, industrial processes, large HVAC systems.

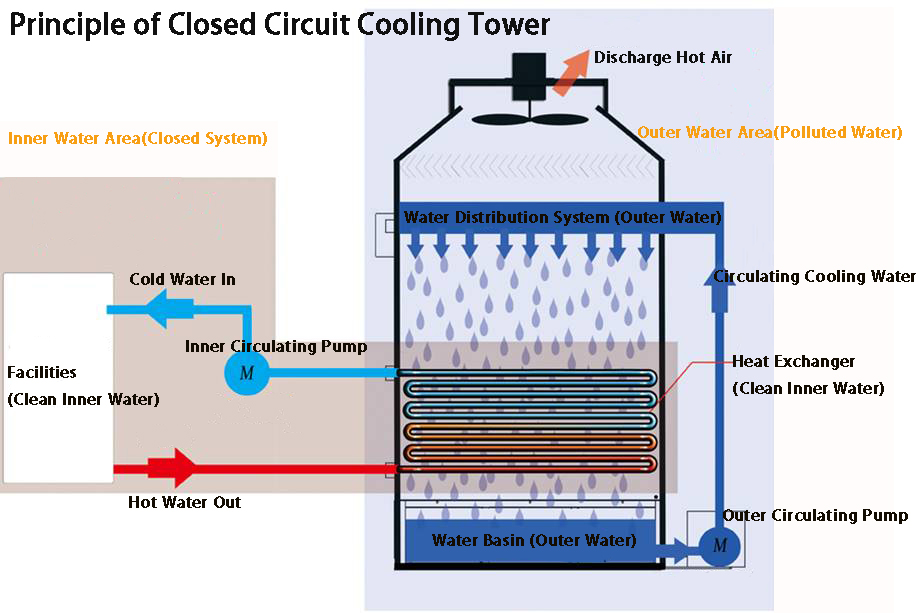

Here, process fluid flows inside coils while being cooled by spray water and air. This keeps the fluid clean and protected.

Common uses: Chemical, pharmaceutical, and precision industrial processes.

Dry cooling towers use air only, without evaporation.

Common uses: Water-scarce regions and environmentally sensitive sites.

Cooling towers are used anywhere large amounts of heat must be removed.

Cooling towers remove heat from steam condensers, enabling efficient electricity generation.

In commercial buildings, cooling towers reject heat from chillers, keeping indoor spaces comfortable year-round.

Steel plants, refineries, food processing facilities, and chemical plants all rely on cooling towers to maintain stable production temperatures.

Why use a cooling tower instead of fresh water or mechanical cooling alone?

Cooling towers reduce energy and water costs by recycling cooled water efficiently.

Although evaporation occurs, cooling towers use far less water than once-through cooling systems.

Lower operating temperatures reduce corrosion, scaling, and thermal stress.

Compared with chillers or once-through systems, cooling towers:

Handle larger heat loads

Consume less energy

Offer better long-term operating economics

They are the backbone of large-scale cooling.

Modern cooling towers are designed to minimize:

Water drift losses

Noise levels

Chemical discharge

With proper operation, they are environmentally responsible solutions.

Each component plays a vital role in fulfilling the cooling tower’s purpose:

Fill: increases heat transfer surface

Fan: moves air through the tower

Drift eliminator: reduces water loss

Basin: collects cooled water

❌ Cooling towers cool air → They cool water

❌ Cooling towers waste water → They save water overall

❌ Cooling towers are outdated → They are essential for modern efficiency

The right cooling tower depends on:

Heat load

Climate conditions

Water quality

Space and noise requirements

A well-selected cooling tower delivers reliable performance for decades.

The true purpose of a cooling tower goes far beyond cooling water. It supports energy efficiency, system reliability, sustainability, and cost control. Like a silent guardian, it protects equipment from overheating while keeping industrial and commercial systems running smoothly.

In today’s world of rising energy costs and environmental responsibility, cooling towers are not optional—they are essential.