We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-13 Origin: Site

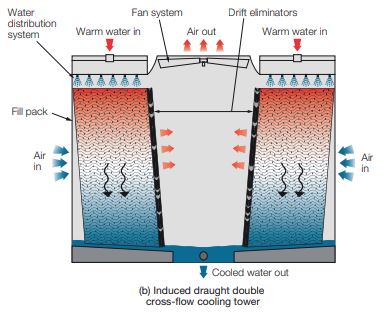

A drift eliminator is a critical internal component of a water cooling tower and an essential part of any modern water cooling tower system. Its primary function is to reduce water loss by capturing and redirecting water droplets carried by the exhaust air stream. These droplets, known as “drift,” can contain minerals and cooling tower water treatment chemicals, making effective drift control vital for water conservation, environmental protection, and system efficiency.

Manufacturers such as Mach Cooling (https://www.machcooling.com/) design high-efficiency cooling towers with advanced cooling tower water drift eliminator systems to meet industrial, commercial, and HVAC performance requirements.

Cooling tower drift refers to liquid water droplets that escape the tower with the outgoing air during operation. Unlike evaporation losses, drift is avoidable and represents both water loss and chemical loss from the system.

Drift commonly occurs in:

Water cooled towers

Closed loop cooling towers

Open evaporative water cooling tower systems

Uncontrolled drift can lead to:

Increased water consumption

Loss of cooling tower water treatment chemicals

Corrosion of nearby equipment and structures

Environmental and regulatory concerns

This is why a properly designed drift eliminator is indispensable.

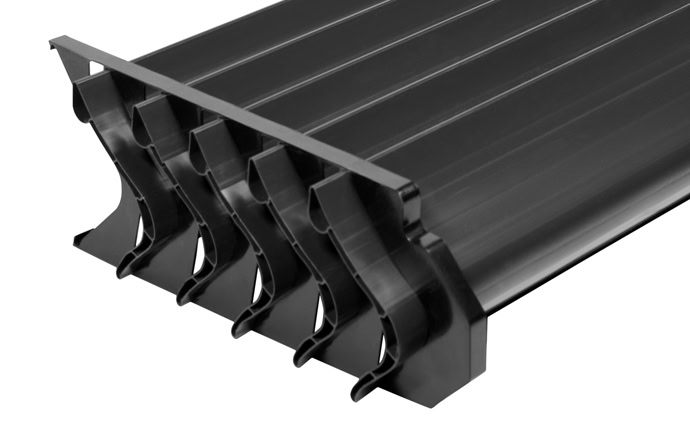

A drift eliminator is a specially shaped assembly of blades or channels installed in the airflow path of a cooling tower. Its role is to change the direction of airflow multiple times, forcing entrained water droplets to collide with surfaces, coalesce, and fall back into the tower.

By capturing droplets before air exits the tower, a cooling tower water drift eliminator significantly reduces water carryover.

As warm, moisture-laden air rises through the cooling tower:

Air passes through the drift eliminator channels

Airflow direction changes multiple times

Water droplets impact eliminator surfaces

Droplets merge and drain back into the tower

This process allows air to exit while water remains inside the system.

Because drift droplets often contain cooling tower water treatment chemicals, effective eliminators:

Reduce chemical consumption

Maintain stable water chemistry

Support long-term system reliability

This is especially important in high-performance water cooling tower systems.

The most common design, using multiple angled blades to create sharp airflow turns.

Advantages:

High drift removal efficiency

Low pressure drop

Suitable for most industrial applications

These use compact cell structures to trap droplets.

Advantages:

High surface contact

Compact design

Ideal for space-constrained towers

In closed loop cooling towers, drift eliminators protect:

Heat exchange coils

Surrounding equipment

External environments

Even though process fluid is isolated, drift control remains critical for spray water management.

Lightweight and cost-effective

Resistant to corrosion and chemicals

Widely used in water cooled towers

Higher temperature resistance

Better performance with aggressive water chemistry

Suitable for industrial systems using strong treatment programs

Material choice depends on:

Operating temperature

Chemical exposure

UV and environmental conditions

Mach Cooling selects materials optimized for durability and efficiency.

| Drift Eliminator Type | Typical Drift Loss | Pressure Drop | Common Application |

|---|---|---|---|

| Basic Blade Type | 0.02–0.03% | Low | Standard water cooling tower |

| High-Efficiency Blade | ≤0.001% | Very Low | Industrial water cooling tower system |

| Cellular Type | ≤0.002% | Medium | Compact or HVAC systems |

| Advanced Mach Cooling Design | ≤0.001% | Optimized | High-efficiency towers |

In open water cooling towers, drift eliminators minimize water loss and improve overall system efficiency, especially under high airflow conditions.

For industrial water cooled towers, effective drift control protects nearby structures and ensures compliance with environmental standards.

Even in closed loop cooling towers, drift eliminators prevent spray water loss and chemical dispersion while maintaining heat rejection performance.

Reducing drift means less makeup water is required, lowering operating costs.

By retaining cooling tower water treatment chemicals, the system operates more efficiently and economically.

Proper drift control minimizes chemical emissions and visible plume contamination.

Stable water chemistry and reduced corrosion extend equipment lifespan.

Mach Cooling (https://www.machcooling.com/) integrates advanced cooling tower water drift eliminator designs into its cooling towers, offering:

High drift removal efficiency

Low airflow resistance

Compatibility with modern water cooling tower systems

Long service life in industrial and HVAC environments

Mach Cooling’s solutions are engineered to support efficient heat rejection while minimizing water and chemical losses.

Check for:

Physical damage

Blockage from debris

Warping due to heat or UV exposure

Periodic cleaning prevents fouling and ensures consistent airflow and drift capture performance.

A drift eliminator in a cooling tower is a vital component that prevents water droplets from escaping with exhaust air. By reducing drift, it conserves water, retains cooling tower water treatment chemicals, protects the environment, and enhances overall cooling tower efficiency.

Whether used in a water cooling tower, water cooled tower, or closed loop cooling tower, a well-designed cooling tower water drift eliminator is essential for modern cooling systems. With engineered solutions from Mach Cooling, operators can achieve superior drift control, lower operating costs, and long-term system reliability.