We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-11 Origin: Site

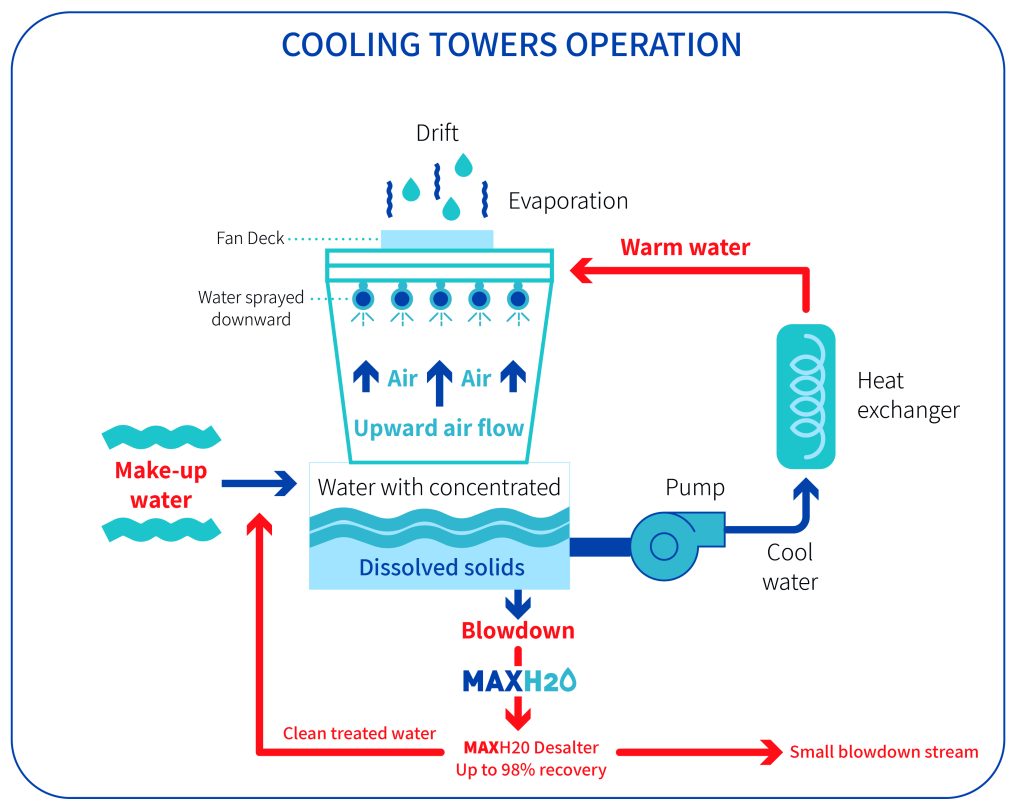

A “cooling tower screen” refers to one or more protective mesh or filter panels employed in a cooling tower or associated cooling-water system to prevent debris, leaves, dust, or other contaminants from entering critical water- and air-flow paths. In large systems — whether a water cooling tower system, a condenser water cooling tower, a chilled water cooling tower, or even a closed loop cooling tower — screens play a vital role in maintaining performance, protecting pumps and heat-exchange surfaces, and reducing maintenance need and downtime.

In this article we explain what cooling tower screens are, why they’re used, how they work, their different types, where they are installed, and the benefits and considerations — with relevance to products from MACH Cooling.

Cooling towers draw large volumes of air and water. As ambient air is drawn in (via louvers or inlets), dust, leaves, pollen, insect bodies, or other airborne debris can be entrained. Similarly, water used in the tower or in its makeup water may carry small debris or particulate matter. Without protection, this debris can:

Clog or foul fill media, spray nozzles, or drift eliminators.

Damage pumps or downstream heat-exchangers via abrasion or blocking suction strainers.

Reduce air- and water-flow efficiency, undermining cooling performance.

Raise maintenance needs, downtime, and risk of unplanned shutdowns.

For these reasons, many cooling-tower systems, especially industrial or large-scale ones, equip “cooling tower screens” as part of their design and water-intake protection strategy.

A cooling tower screen (also called an air-intake screen, water screen, sump screen, or simply a “screen/filter”) is a mesh or perforated barrier placed at air inlets, sump/pump suction points, or other critical flow passages in a cooling tower / water-cooling system. Its aim is to catch and block debris — such as leaves, dust, insects, small sticks — before they can enter the tower and cause damage or fouling.

Some screens are stationary (fixed mesh); others are traveling (moving / conveyor-type) for continuous debris removal and reduced clogging.

Protect air-inlet paths: prevent airborne debris from entering and clogging fill media or internal components.

Protect water-circulation components: at the sump or pump inlet, screens block debris that could damage pumps or reduce flow.

Improve system longevity and reliability: by preventing fouling, screens help ensure stable operation, reduce maintenance, and avoid unplanned downtime.

Maintain heat-transfer efficiency: by ensuring fills, spray nozzles, drift eliminators stay clean, the tower can operate at design performance.

Cooling-tower screens come in different types depending on where they are used and the intended degree of protection.

Air-intake / air-inlet screens: Installed at the louvers or air-inlet openings of the tower to block leaves, dust, pollen, and other airborne debris before air enters the fill zone.

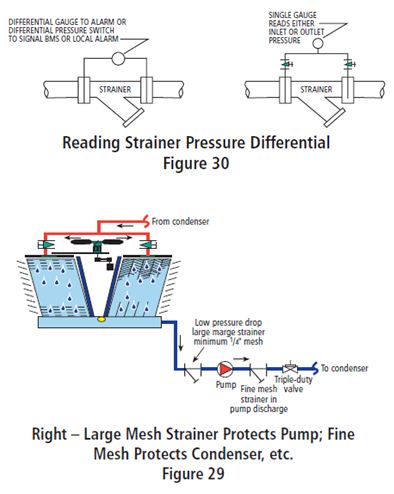

Sump / suction-pit screens: Placed over or inside the water basin or pump suction area to stop debris from entering pumps, pipelines, or heat exchangers.

Static water-screens for blowdown / makeup water lines: When makeup water or blowdown water is drawn from an open source (e.g. pond, lake, or open reservoir), a screen helps filter out leaves, algae, or aquatic debris. Many such “cooling tower water screens” are offered by specialized filter-screen manufacturers.

| ✅ Advantages | ⚠️ Limitations / Maintenance Needs |

|---|---|

| Simple, low-cost installation | Can accumulate debris and clog — requires periodic manual cleaning |

| Provides basic protection for air & water intake | When clogged, can restrict airflow or water flow, reducing cooling performance |

| Good for light-duty or smaller installations | Debris buildup over time may lead to increased head pressure on fans or pumps |

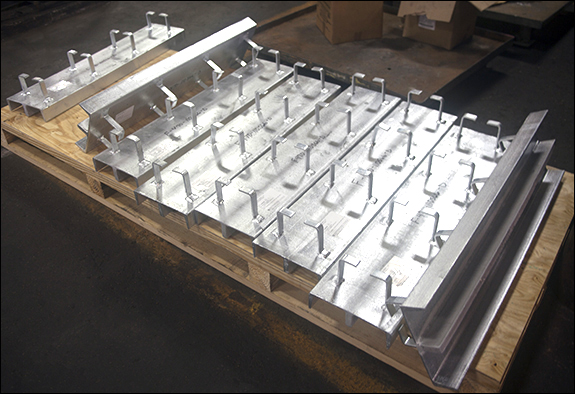

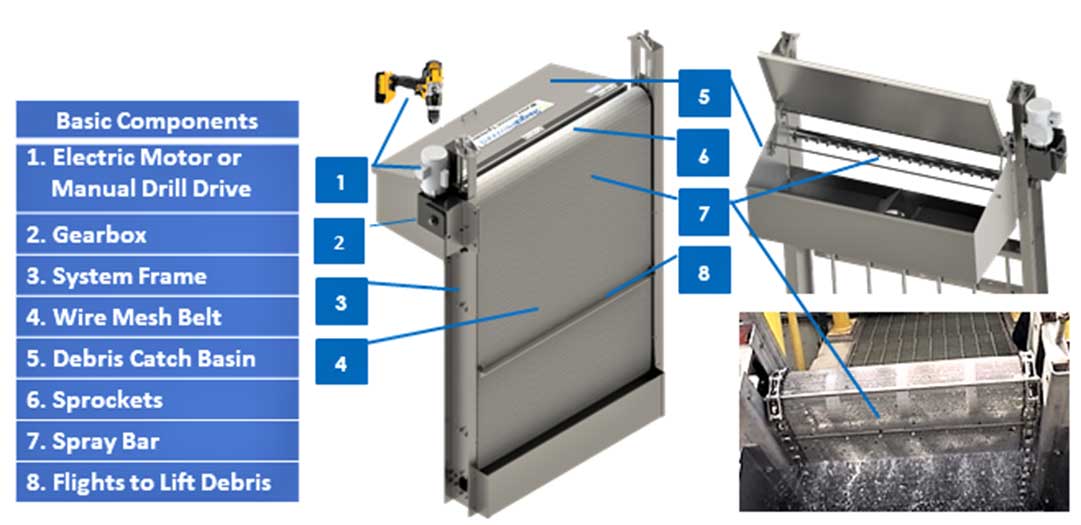

These screens move (e.g., via conveyor or rotating mesh) to continuously or periodically remove debris that accumulates, typically in water-intake or sump applications.

Often made of heavy-duty materials (stainless steel, coated steel, UHMW liners) to resist wear.

Some traveling screens include spray-bars to wash off debris into a disposal channel before it reaches suction pumps, improving reliability and extending maintenance intervals.

These are especially valuable in large industrial cooling towers, power plants, or facilities using open-water makeup sources, where debris load is constant and manual cleaning would be impractical.

Continuous or scheduled cleaning reduces clogging risk.

Protects pumps, strainers, and downstream heat exchangers more reliably than fixed screens.

Reduces downtime and maintenance labor; extends equipment lifespan.

Depending on the type of cooling tower system — e.g., condenser water cooling tower, chilled water cooling tower, closed loop cooling tower, or blowdown water cooling tower — the role and placement of screens may vary.

| Cooling Tower System Type | Typical Screen Usage / Considerations |

|---|---|

| Open circuit condenser water cooling tower / chilled water cooling tower | Air-intake screens to prevent leaves/dust from fouling fill and drift eliminators; sump or pump-suction screens to protect pumps from debris or scale; water-makeup screens if using open water source. |

| Blowdown water cooling tower (open loop with periodic bleed-off) | Water-intake / makeup-water screens help keep debris out; sump screens protect pumps as blowdown water may carry sediment, scale, or algae. |

| Closed loop cooling tower (closed-circuit) | While the process fluid is sealed in coils, the external spray-water or air-intake loops still need protection — air-intake screens and possibly sump/water-screens to protect spray-water recirculation pumps. |

| Large industrial / plant-scale towers | Traveling water screens are especially useful when intake water comes from open sources (rivers, cooling ponds) or when debris load is high (e.g. leaves, algae), reducing maintenance and downtime risk. |

For a manufacturer like MACH Cooling offering a full line of cooling-tower solutions, integrating appropriately selected screens into the design of a water cooling tower system — whether open-circuit or closed-loop — helps ensure long-term reliability, performance, and reduced maintenance burden.

Protection of critical components: Screens prevent debris from damaging or clogging fans, drift eliminators, fill media, nozzles, pumps, and heat exchangers.

Improved longevity and reliability: Reducing the chance of fouling or damage helps prolong service life and reduces unplanned downtime.

Water- and energy-efficiency: By keeping internal components clean, screens help maintain consistent water flow and airflow — which supports stable evaporative cooling performance and efficient heat rejection.

Reduced maintenance labour: Fixed screens require periodic cleaning — but traveling/self-cleaning screens greatly reduce manual maintenance and associated downtime.

Airflow or water-flow restriction: If screens become clogged and are not cleaned, they can restrict airflow (in air-intake screens) or water suction — reducing cooling tower performance or damaging pumps.

Maintenance required: Fixed screens especially need regular inspection and cleaning. Traveling screens reduce but do not eliminate maintenance; they may require periodic servicing and check of mechanical components.

Initial and upgrade costs: Installing high-quality fixed or traveling screens adds cost. For older towers, retrofitting may require downtime and design adaptation.

Material & durability: Screens must resist corrosion, UV, wear, especially in harsh climates or with water treatment chemicals. High-quality materials (e.g. stainless steel, coated steel, UV-resistant plastics) are preferred.

While many towers — water cooled towers, condenser water cooling towers, chilled water cooling towers, closed loop cooling towers, or blowdown water cooling towers — benefit from screening, a manufacturer like MACH Cooling can integrate screens into their water cooling tower systems to improve overall reliability and maintenance convenience.

Some example ways MACH Cooling might use screens:

Fit air-intake mesh screens at the inlet louvers of their towers to block dust, leaves, and airborne debris, protecting fill media and internal components.

Incorporate sump / pump-suction screens or strainers to prevent debris or particulate matter from entering pumps — especially important when towers are used in industrial environments or with non-treated water.

Offer optional traveling / self-cleaning water screens for large or industrial-scale installations, where makeup or blowdown water draws from open sources or when debris load is expected to be high.

Provide maintenance guidelines for cleaning or replacing screens, especially for fixed screens, to ensure system remains efficient and cooling performance is not compromised.

By doing so, MACH Cooling’s water cooling tower system offerings — whether open or closed loop — would not only deliver effective thermal performance, but also improved durability, safer operation, and lower lifetime maintenance cost.

Here is a simplified schematic table of typical cooling-tower components — including where screens are typically placed — for reference:

| Component / Location | Role in Tower / System | Typical Screen Use / Notes |

|---|---|---|

| Air Inlet / Louvers | Entry point for ambient air for evaporative cooling | Air-intake screen to block leaves, dust, pollen, insects |

| Fill media / packing & drift eliminators | Provide large water-air contact area; recover droplets from airflow | Screens upstream help to prevent dust/particles from fouling these sensitive surfaces |

| Basin / sump / pump suction | Collect cooled water and supply pumps driving recirculation | Sump / suction screens or water-screens to protect pumps and prevent debris ingress |

| Makeup water / blowdown intake (if from open source) | Source for makeup water or drain-off water | Water-screens / intake filters to stop external debris, algae, vegetation, etc. |

A cooling tower screen — whether an air-intake mesh, a sump/pump suction screen, or a self-cleaning traveling water screen — is a small but critical part of a reliable, efficient water cooling tower system. Especially in large-scale systems like condenser water cooling towers, chilled water cooling towers, blowdown water cooling towers, or closed loop cooling towers provided by manufacturers such as MACH Cooling, screens help prevent debris and contaminants from undermining performance, damaging components, or increasing maintenance burden.

While screens add a modest initial cost and require maintenance (particularly fixed screens), their benefits — in terms of reduced downtime, longer equipment life, and stable cooling efficiency — generally make them well worth the investment.

If you like, I can also draft a schematic infographic that shows a cooling tower with recommended screen placements (air inlet, sump, makeup water) — this might help you visualize where screens belong and why they matter.