We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-24 Origin: Site

A cooling tower is a critical part of industrial and HVAC heat rejection systems. To ensure safe operation, efficient maintenance, and reliable system control, various valves are installed in cooling tower piping. Among them, the cooling tower isolation valve plays a fundamental role.

This article provides a complete and practical explanation of what a cooling tower isolation valve is, how it works, where it is used, and why it is essential. The content also reflects engineering practices commonly applied by professional cooling tower manufacturers such as Mach Cooling (https://www.machcooling.com/).

A cooling tower isolation valve is a valve installed in the cooling tower water system to completely shut off or isolate water flow to a specific section of the system. Its main function is not to regulate flow but to allow maintenance, repair, or inspection without draining or shutting down the entire cooling tower system.

In cooling tower applications, isolation valves are commonly used on:

Cooling tower inlet piping

Cooling tower outlet piping

Pump suction and discharge lines

Heat exchanger connections

Bypass and make-up water lines

By closing an isolation valve, operators can safely separate one component from the rest of the system.

Cooling tower systems handle large volumes of circulating water. Isolation valves allow operators to stop water flow instantly, preventing flooding, equipment damage, and safety hazards during maintenance or emergencies.

With properly installed isolation valves:

Maintenance can be performed on pumps, strainers, or cooling tower cells

Only the isolated section is shut down

The remaining system continues operating

This significantly reduces plant downtime and operational losses.

Isolation valves protect cooling tower components from:

Sudden pressure surges

Uncontrolled water discharge

Backflow during system shutdown

For industrial users, this protection extends equipment life and improves system reliability.

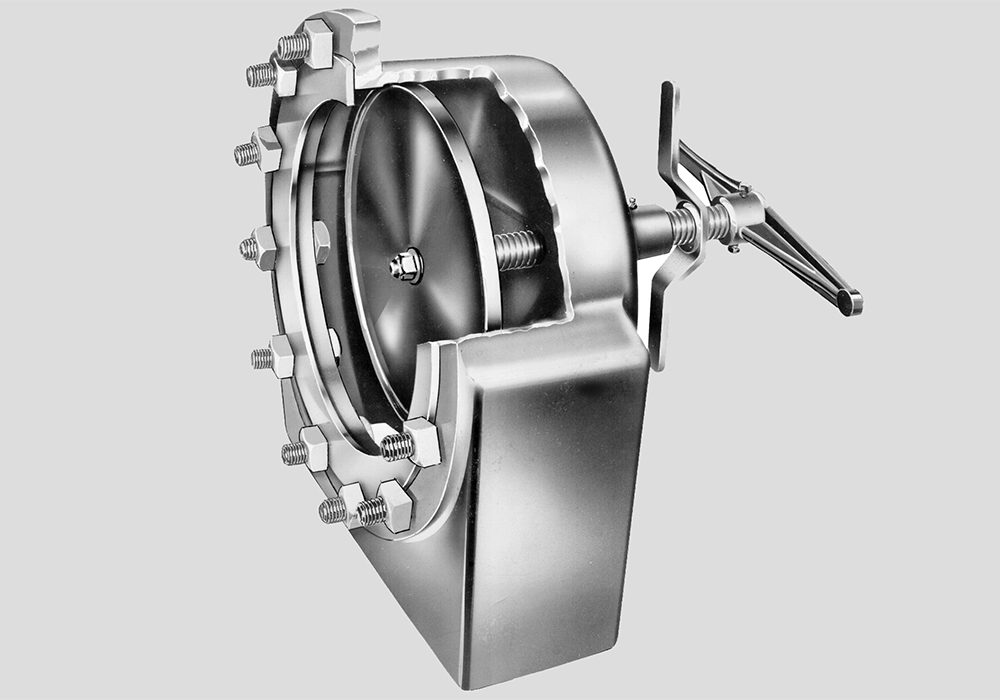

Isolation valves are defined by their function, not their design. Several valve types can serve as isolation valves in cooling tower systems.

Fast on/off operation

Excellent sealing performance

Common for small to medium pipe sizes

Lightweight and cost-effective

Ideal for large-diameter cooling tower piping

Widely used in industrial cooling tower installations

Full open or full close operation

Minimal pressure drop when fully open

Slower to operate compared to ball valves

Better for flow regulation

Higher pressure drop

Less commonly used purely as isolation valves

| Valve Type | Typical Pipe Size | Sealing Performance | Cost Level | Cooling Tower Application |

|---|---|---|---|---|

| Ball Valve | Small–Medium | Excellent | Medium | Make-up water, branch lines |

| Butterfly Valve | Medium–Large | Good | Low | Inlet & outlet main piping |

| Gate Valve | Medium–Large | Good | Medium | Main isolation points |

| Globe Valve | Small–Medium | Moderate | High | Rarely used for isolation |

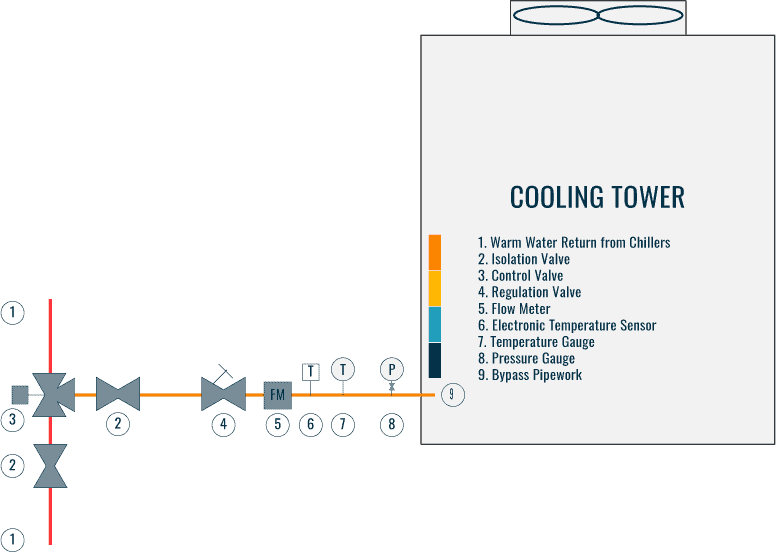

Isolation valves are strategically installed to maximize operational flexibility:

Cooling tower water inlet – isolates the tower from the condenser water loop

Cooling tower outlet – prevents backflow during shutdown

Pump suction and discharge – allows pump servicing

Heat exchanger connections – enables maintenance without draining the system

Bypass lines – supports system balancing and testing

Proper valve placement is a standard design practice followed by professional cooling tower manufacturers like Mach Cooling.

Isolation valve materials must withstand continuous water exposure and chemical treatment:

Cast iron

Ductile iron

Carbon steel

Stainless steel

Bronze (for smaller systems)

Material selection depends on:

Water quality

Operating temperature

System pressure

Chemical treatment program

When choosing a cooling tower isolation valve, consider:

Pipe diameter and flow rate

System pressure and temperature

Water chemistry and corrosion risk

Manual or automated operation

Installation space and maintenance access

A professional cooling tower supplier such as Mach Cooling can provide system-level guidance to ensure valve selection matches overall cooling tower performance requirements.

| Feature | Isolation Valve | Control Valve |

|---|---|---|

| Primary function | Shut off flow | Regulate flow |

| Operation | Fully open / fully closed | Modulating |

| Usage in cooling tower | Maintenance & safety | Flow balancing |

| Complexity | Simple | More complex |

Isolation valves are not designed to regulate flow continuously; their strength lies in reliable shut-off.

Modern cooling tower systems emphasize:

Energy efficiency

Easy maintenance

Operational reliability

Isolation valves are a core part of this design philosophy. High-quality cooling tower systems from Mach Cooling integrate well-positioned isolation valves to support long-term operation, reduce downtime, and improve overall system safety.

A cooling tower isolation valve is an essential component that allows operators to safely and efficiently manage water flow within a cooling tower system. By enabling section-by-section shutdown, isolation valves reduce maintenance time, enhance safety, and protect valuable equipment.

When properly selected and installed, isolation valves contribute significantly to the reliability and efficiency of industrial and HVAC cooling systems. Working with an experienced manufacturer such as Mach Cooling (https://www.machcooling.com/) ensures that cooling towers and their associated piping components are engineered for durability, performance, and ease of maintenance.