We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-13 Origin: Site

Blowdown is a fundamental operational process in any water cooling tower or water cooling tower system. Its primary purpose is to control water quality by removing a portion of concentrated circulating water and replacing it with fresh make-up water. Without proper blowdown, dissolved solids, minerals, and cooling tower water treatment chemicals would accumulate, leading to scaling, corrosion, fouling, and reduced heat transfer efficiency.

Whether applied in a water cooled tower, closed loop cooling tower, blowdown water cooling tower, or chilled water cooling tower, blowdown plays a critical role in maintaining stable, efficient, and reliable cooling performance. High-quality cooling solutions from Mach Cooling (https://www.machcooling.com/) are engineered to support precise blowdown control and long-term system efficiency.

Cooling tower blowdown is the intentional discharge of a controlled volume of circulating water from the cooling tower basin or piping system. This process removes water that has become concentrated due to evaporation.

When water evaporates in a cooling tower:

Pure water vapor leaves the system

Dissolved solids remain behind

Mineral concentration increases

Blowdown prevents excessive buildup of these contaminants.

The most important purpose of blowdown is to limit Total Dissolved Solids (TDS) in circulating water. High TDS levels can cause scale formation on heat transfer surfaces.

Without blowdown:

Calcium carbonate scale forms on fill and heat exchangers

Fouling reduces airflow and water distribution

Cooling capacity decreases

Blowdown works together with cooling tower water treatment chemicals to prevent these issues.

High concentrations of chlorides and sulfates accelerate corrosion in metal components. Blowdown helps keep corrosive ions within acceptable limits.

By removing nutrient-rich water, blowdown helps limit algae, bacteria, and biofilm growth, supporting chemical and mechanical water treatment programs.

In a water cooling tower, evaporation is essential for heat rejection. However, evaporation leaves minerals behind, increasing concentration levels. Blowdown balances this effect.

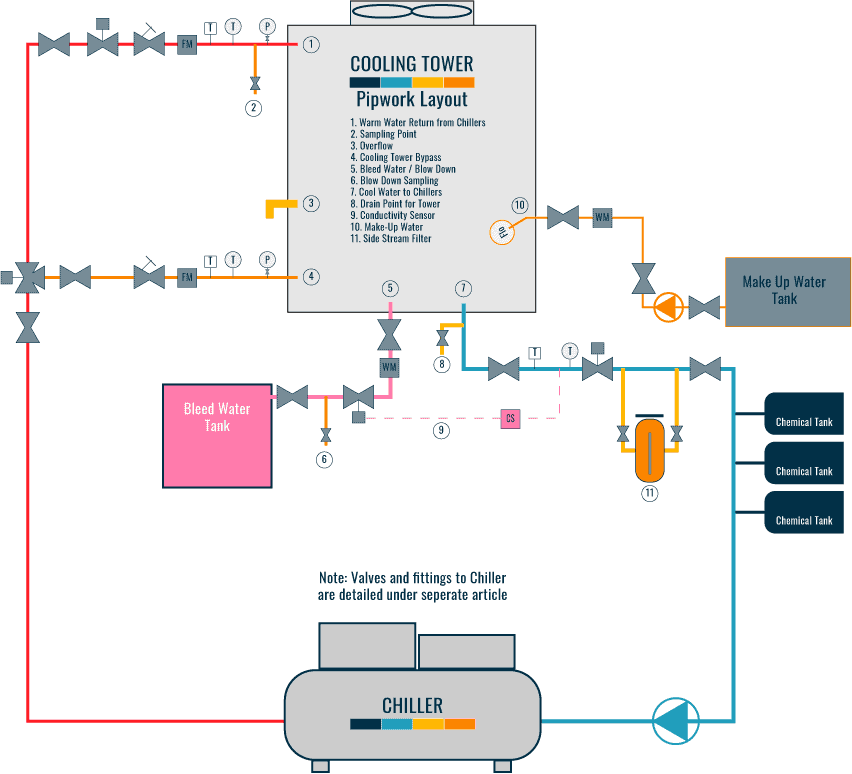

Blowdown is directly linked to make-up water. Fresh water dilutes the system after blowdown, restoring water quality and stabilizing system operation.

Make-Up Water=Evaporation Loss+Drift Loss+Blowdown Loss

In open-loop blowdown water cooling towers, blowdown is continuous or intermittent to control cycles of concentration and maintain performance.

Industrial water cooled towers handling heavy heat loads require precise blowdown control to avoid rapid scale formation.

In a closed loop cooling tower, the process fluid is isolated, but the spray water loop still requires blowdown to manage evaporation-related concentration.

In chilled water cooling towers used in HVAC plants, blowdown ensures stable heat rejection for chillers and reliable cooling tower chilled water system operation.

Blowdown works in coordination with cooling tower water treatment chemicals, including:

Scale inhibitors

Corrosion inhibitors

Biocides

Proper blowdown prevents over-concentration of chemicals while maintaining effective protection.

Correct blowdown rates:

Reduce chemical overuse

Improve treatment efficiency

Lower operating costs

Cycles of concentration (COC) represent the ratio of dissolved solids in circulating water to those in make-up water.

Higher cycles mean less blowdown but higher scaling risk.

| Cycles of Concentration | Blowdown Rate | Water Use Impact |

|---|---|---|

| 2–3 | High | High water consumption |

| 4–6 | Moderate | Balanced operation |

| 7–10 | Low | High efficiency, careful control |

Operator-controlled valves discharge water periodically. This method is simple but less precise.

Conductivity-based systems automatically regulate blowdown based on water quality, offering higher efficiency and reliability.

Stable water chemistry

Reduced water waste

Improved system reliability

Scale buildup

Corrosion

Reduced cooling efficiency

Increased maintenance costs

Water waste

Higher make-up water demand

Increased chemical consumption

Proper balance is essential for any water cooling tower system.

Mach Cooling (https://www.machcooling.com/) designs cooling towers with optimized features that support efficient blowdown operation, including:

Basin designs that promote uniform water quality

Compatibility with automatic blowdown control systems

Stable performance across water cooling towers, closed loop cooling towers, and chilled water cooling towers

Long-term reliability under industrial operating conditions

Mach Cooling solutions help operators achieve optimal cycles of concentration while minimizing water and chemical consumption.

The purpose of blowdown in a cooling tower is to control water quality, prevent scale and corrosion, and maintain efficient heat transfer. By removing concentrated circulating water and replacing it with fresh make-up water, blowdown protects system components and ensures stable operation.

In water cooling towers, water cooled towers, closed loop cooling towers, and chilled water cooling tower systems, properly managed blowdown works hand in hand with cooling tower water treatment chemicals to deliver reliable and efficient cooling performance. With engineered solutions from Mach Cooling, cooling tower systems achieve improved efficiency, reduced operating costs, and extended equipment life.