We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-13 Origin: Site

In any water cooling tower or water cooling tower system, water is continuously lost due to evaporation, drift, and blowdown. To maintain stable operation, these losses must be replaced. This replacement water is known as cooling tower make-up water. Understanding what make-up water is, why it is needed, how it is calculated, and how it is controlled is essential for efficient operation of a water cooled tower, closed loop cooling tower, or chilled water cooling tower.

Manufacturers like Mach Cooling (https://www.machcooling.com/) design cooling towers and auxiliary components to ensure accurate make-up water control, reliable water balance, and long-term system efficiency.

Cooling tower make-up water is the fresh water supplied to a cooling tower to replace water losses and maintain the correct operating water level in the basin.

These losses mainly include:

Evaporation loss

Drift loss

Blowdown loss

Without make-up water, the cooling tower would experience falling water levels, unstable circulation, higher concentrations of dissolved solids, and reduced cooling performance.

Evaporation is the primary cooling mechanism in a water cooling tower. As water evaporates, heat is removed, but the evaporated water must be replaced with make-up water.

Even with efficient drift eliminators, a small amount of water droplets escapes with exhaust air. This water loss must be compensated by cooling tower makeup water.

In a blowdown water cooling tower, blowdown removes concentrated minerals and cooling tower water treatment chemicals to control scaling and corrosion. Blowdown directly increases make-up water demand.

Make-up water dilutes dissolved solids and supports effective water treatment, ensuring reliable performance of the water cooling tower system.

In open water cooled towers, make-up water directly replaces evaporated and discharged water, making accurate level control essential for stable operation.

Although process fluid is isolated in a closed loop cooling tower, make-up water is still required for the spray water loop to replace evaporation and blowdown losses.

In chilled water cooling towers used with chillers, make-up water ensures proper heat rejection and stable cooling tower chilled water system performance.

The cooling tower inlet and outlet water temperature difference (range) directly affects evaporation rate. Higher inlet temperatures lead to greater evaporation and increased cooling tower make-up water demand.

A system with:

Higher heat load

Larger temperature drop

will require more make-up water than a lightly loaded system.

Make-Up Water=Evaporation Loss+Drift Loss+Blowdown Loss

A commonly used approximation:

Evaporation Loss (m³/h)=0.00085×Circulation Flow×Temperature Range

| Item | Value |

|---|---|

| Circulating Flow | 1000 m³/h |

| Temperature Range | 10 °C |

| Evaporation Loss | 8.5 m³/h |

| Cycles of Concentration | 4 |

| Blowdown Loss | 2.8 m³/h |

| Drift Loss | 0.1 m³/h |

| Total Make-Up Water | 11.4 m³/h |

This is a typical cooling tower make-up water calculation used in system design.

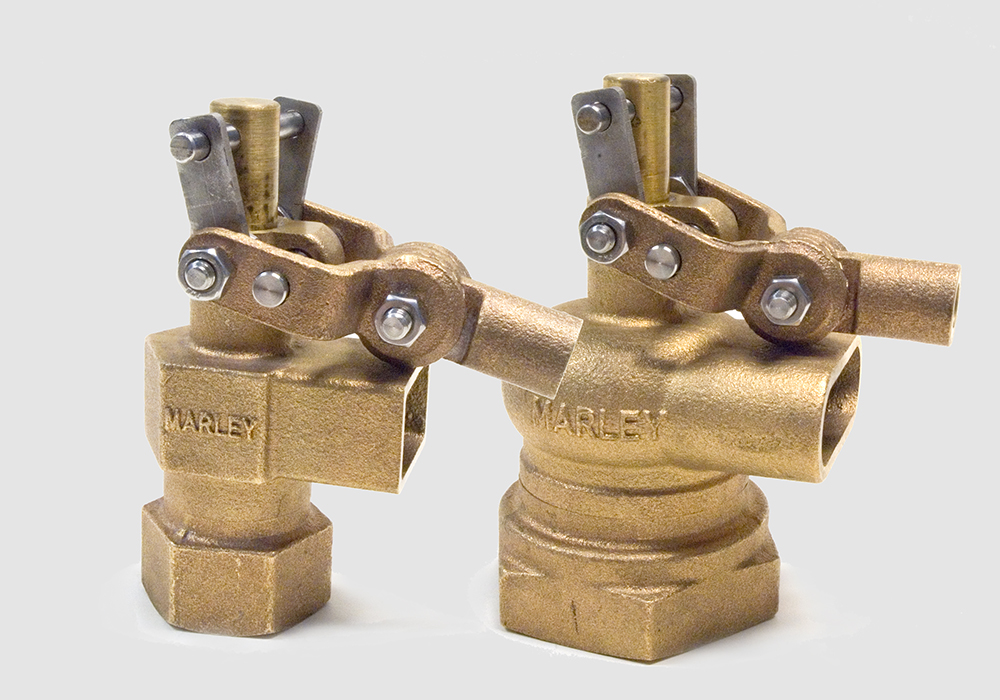

A cooling tower make-up water valve automatically regulates the flow of make-up water based on basin water level.

Mechanical float valves

Electronic level control valves

Solenoid valves with level sensors

Accurate valve control:

Prevents overflow

Avoids pump cavitation

Maintains stable water chemistry

Make-up water introduces fresh minerals and impurities into the system. Proper dosing of cooling tower water treatment chemicals is required to control:

Scale formation

Corrosion

Biological growth

Key parameters include:

Hardness

TDS

pH

Chlorides

Water quality directly influences blowdown rate and overall cooling tower makeup water consumption.

Accurate cooling tower make-up water calculation minimizes unnecessary water use.

Efficient make-up control reduces:

Water bills

Chemical usage

Energy consumption

Stable water levels support pumps, fans, and heat exchange surfaces, extending equipment life.

Mach Cooling (https://www.machcooling.com/) designs advanced cooling towers and systems that support efficient make-up water management, including:

Optimized basin design

Compatible cooling tower make-up water valves

Support for blowdown water cooling tower operation

Reliable performance across water cooling towers, closed loop cooling towers, and chilled water cooling towers

Mach Cooling solutions help customers balance water efficiency, system stability, and long-term operational performance.

Make-up water in a cooling tower is essential for replacing water lost through evaporation, drift, and blowdown. Proper management of cooling tower make-up water ensures stable operation, effective heat rejection, and controlled water chemistry across all cooling tower types.

By understanding cooling tower make-up water calculation, selecting the right cooling tower make-up water valve, and integrating proper water treatment strategies, operators can significantly improve the performance of a water cooling tower system. With engineered solutions from Mach Cooling, cooling towers achieve reliable operation, reduced water consumption, and long-term efficiency.