We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-17 Origin: Site

In a water cooling tower — a key part of many HVAC and industrial water cooling tower systems — components that might seem simple can have a big impact on overall performance and efficiency. One such component is the Cooling tower louvers. They play a critical role in controlling airflow, protecting the tower interior, and improving water distribution and evaporation efficiency.

This article explains what louvers are, how they work, why they matter in cooling water tower design, and how they influence system performance, including cooling tower water supply and cooling tower water tank operation. We also highlight considerations for selecting louvers and include practical comparison tables and visual explanations. Where applicable, we reference trusted water cooling tower manufacturers such as Mach Cooling (https://www.machcooling.com/) — known for engineered cooling systems that balance performance and water cooling tower price.

Cooling tower louvers are slatted or finned panels typically installed at the air intake section of a tower. Their primary purpose is to allow ambient air to enter the cooling tower’s fill area while:

Preventing water splash-out

Reducing drift loss

Limiting debris ingress

Supporting airflow distribution evenly across the fill area

Louvers help maintain a stable water cooling tower system by ensuring that airflow enters the tower in a controlled manner, enhancing evaporative cooling and the efficiency of the heat transfer process between hot water and ambient air.

The basic working logic of louvers in a cooling tower is simple, yet essential:

Air Intake Regulation:

Louvers create a passage for air to enter the tower. This air flows through the fill media, contacting the hot recirculating water that arrives via the cooling tower water supply.

Splash Control:

As water descends through the fill, loose droplets can be pushed outward by airflow. Louvers help reduce such water loss.

Debris Prevention:

Outdoor cooling towers may draw in leaves, dust, or other debris. Louvers serve as the first defense, keeping the internal components cleaner.

Even Airflow Distribution:

Uniform airflow allows a consistent cooling effect across the full cross-section of the cooling tower water tank and fill areas.

Without well-designed louvers, airflow can be uneven, leading to hot spots, reduced cooling efficiency, and higher operational costs.

| Feature | Louvers | Open Intake | Screens / Mesh |

|---|---|---|---|

| Airflow Control | ✔ Good | ✘ Poor | ◼ Limited |

| Debris Protection | ✔ Moderate | ✘ None | ✔ High |

| Splash Prevention | ✔ Yes | ✘ No | ◼ Minimal |

| Maintenance Demand | ◼ Medium | ✔ Low | ✘ Can clog |

| Typical Use | Cooling towers | Large dry systems | Supplemental protection |

Louvers often strike a balanced design choice, protecting internal sections while providing good airflow for evaporation — critical in professional cooling water tower design.

The performance of a water cooling tower system depends on how efficiently it can bring ambient air into contact with warm process water. For towers that use forced or induced airflow, louvers support stability and performance by managing how air enters, while eliminating water loss or undesirable splashing.

A cooling tower’s efficiency relates to how closely the cold-water temperature approaches ambient wet bulb conditions. Key factors influenced by louvers include:

Airflow uniformity: Even air distribution reduces areas of poor cooling.

Energy usage: Better airflow often means fans can operate with lower energy draw.

Water conservation: Limiting splash-out reduces makeup water demand.

These factors all tie directly to the cooling water tower design quality and operating economics, including water cooling tower price considerations when balancing initial cost versus ongoing savings.

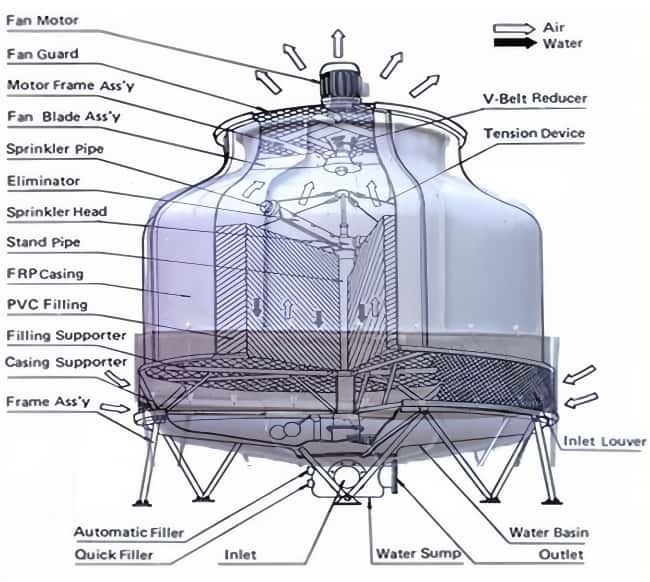

Louvers work in harmony with major cooling tower elements:

Fan Section: Pulls or pushes air through louvers and fill.

Fill Media: Louvers help ensure airflow reaches all sections of fill.

Water Distribution System: Even air distribution makes water spray and fill interaction more effective.

Cooling Tower Water Tank: Collects cooled water with minimal splash loss.

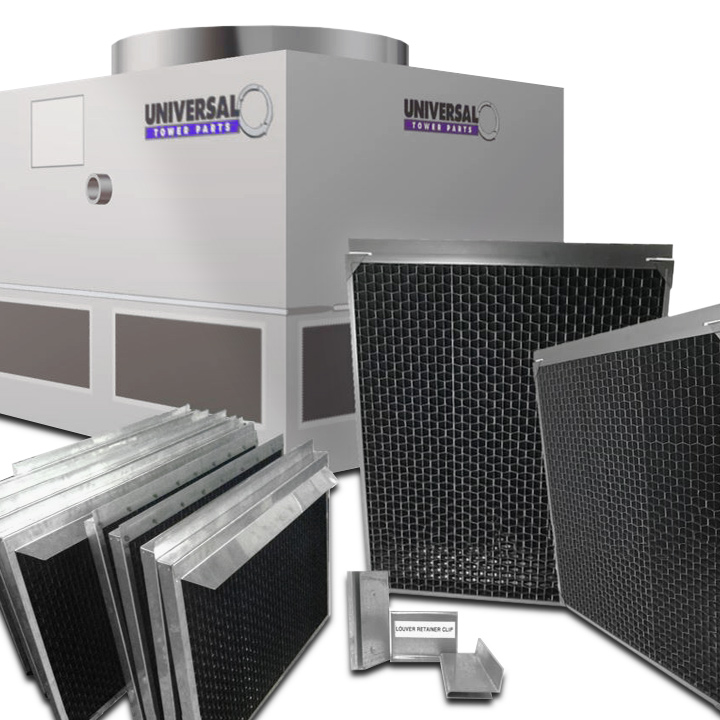

Horizontal Louvers:

Designed to direct airflow in a controlled path while reducing splash-out.

Angled Louvers:

Help manage wind impacts and direct airflow under specific conditions such as crosswinds.

Perforated or Cellular Louvers:

Provide protection against smaller debris and can improve uniform airflow.

| Material | Durability | Cost | Typical Use |

|---|---|---|---|

| PVC / Plastic | Good | ✔ Lower | Standard towers |

| FRP (Fiberglass Reinforced Plastic) | Excellent | ◼ Medium | Corrosive environments |

| Galvanized Steel | Good | ✔ Lower | Industrial towers with protective coatings |

| Stainless Steel | Very High | ✘ Higher | Harsh environments requiring long life |

The choice of material affects both performance and water cooling tower price — higher durability can reduce maintenance costs over the life of the system.

In cooling water tower design, engineers consider:

Ambient conditions

Required airflow volume

Fan capacity

Impact of louvers on static pressure

Poorly designed or undersized louvers can restrict airflow, forcing fans to work harder or reducing cooling capacity.

Uniform airflow is essential for consistent cooling. A key metric in design is:

| Design Metric | Impact |

|---|---|

| Air Velocity Through Fill | Affects evaporation rate |

| Pressure Drop Across Louvers | Impacts fan selection |

| Louvers Spacing & Angle | Controls splash mitigation |

A good cooling tower louvers layout reduces pressure drop while maintaining controlled airflow.

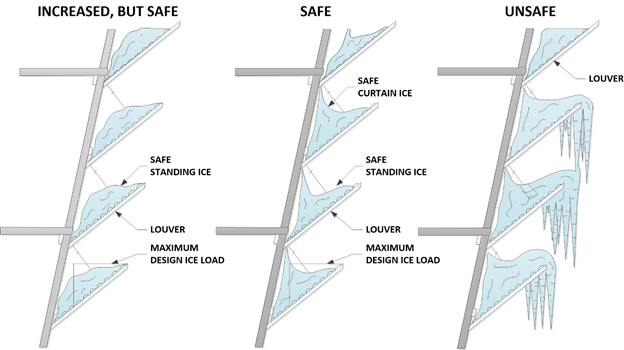

Environmental factors — such as wind, dust, and seasonal temperature shifts — influence cooling tower performance. Louvers help by:

Reducing wind-driven water loss

Filtering larger debris

Improving system stability in gusty conditions

Proper louver selection is especially important in dusty, windy, or coastal installations.

Even though louvers are static (non-moving) components, they require inspection and occasional service:

Cleaning accumulated dust, algae, or debris

Checking for cracks or UV damage (PVC/FRP)

Ensuring mountings and supports are secure

| Problem | Common Cause | Solution |

|---|---|---|

| Airflow restriction | Accumulated debris | Clean or replace louvers |

| Water pooling | Improper tilt/installation | Adjust install angle |

| Corrosion | Material mismatch | Upgrade to corrosion-resistant louver |

Regular maintenance of louvers contributes to long-term performance of the water cooling tower system.

When selecting cooling towers — including considerations for louvers — important factors include:

Performance specifications

Material options and corrosion resistance

Compatibility with fill media and fans

Overall water cooling tower price and lifecycle cost

Mach Cooling (https://www.machcooling.com/) — a seasoned water cooling tower manufacturer — offers cooling towers designed with engineered louvers that balance airflow control and system reliability. Their designs integrate louvers with other critical components, ensuring reliable cooling tower water supply routing and stable operation of the cooling tower water tank.

In a water cooling tower, Cooling tower louvers are more than simple intake panels. They play a key role in regulating airflow, reducing water loss, protecting internal components, and contributing to reliable heat rejection. The proper selection and design of louvers directly affect overall system performance, maintenance needs, and the long-term economics of the cooling installation.

Whether you are implementing a large industrial cooling solution or optimizing an HVAC system, partnering with experienced water cooling tower manufacturers like Mach Cooling ensures that louvers and all cooling tower components are engineered for performance, durability, and value — all while keeping an eye on water cooling tower price, efficiency, and lifecycle serviceability.