We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-17 Origin: Site

A forced draft cooling tower is a commonly used type of water cooling tower designed to remove heat from industrial processes and HVAC systems. As an important component of a modern water cooling tower system, it uses mechanical fans to force ambient air into the tower, enhancing heat transfer between air and circulating water.

Manufactured and supplied by experienced water cooling tower manufacturers such as Mach Cooling (https://www.machcooling.com/), forced draft cooling towers are widely applied in commercial buildings, factories, power plants, and process cooling systems. Their compact structure, controlled airflow, and competitive water cooling tower price make them a practical solution for many projects.

This article explains what a forced draft cooling tower is, how it works, its main components, advantages and limitations, and how it fits into professional cooling water tower design.

A forced draft cooling tower is a mechanical draft cooling tower in which one or more fans are installed at the air inlet to push air into the tower. Unlike induced draft towers that pull air through the system, forced draft towers create positive air pressure inside the structure.

In a complete water cooling tower system, hot water from the process enters the tower, spreads over the fill media, and comes into direct contact with the forced airflow. Heat is removed mainly through evaporation, and the cooled water is collected in the cooling tower water tank for reuse.

The operating process of a forced draft cooling tower can be summarized as follows:

Hot water is delivered from the process via the cooling tower water supply pipeline.

The water distribution system sprays water evenly over the fill.

Fans force ambient air through the fill section.

Heat is transferred from water to air through evaporation and convection.

Cooled water flows into the cooling tower water tank and returns to the system.

This controlled airflow improves cooling stability, especially in locations with variable wind conditions.

| Item | Forced Draft Cooling Tower | Induced Draft Cooling Tower |

|---|---|---|

| Fan position | Air inlet | Air outlet |

| Airflow direction | Pushed into tower | Pulled through tower |

| Internal pressure | Positive | Negative |

| Footprint | Compact | Larger |

| Initial cost | Lower | Higher |

| Common applications | HVAC, small industrial systems | Large industrial systems |

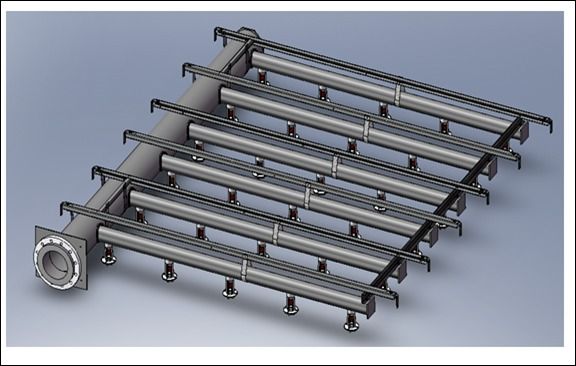

The fan system provides the driving force for airflow. In forced draft designs, fans are installed at the air inlet, making airflow direction easy to control.

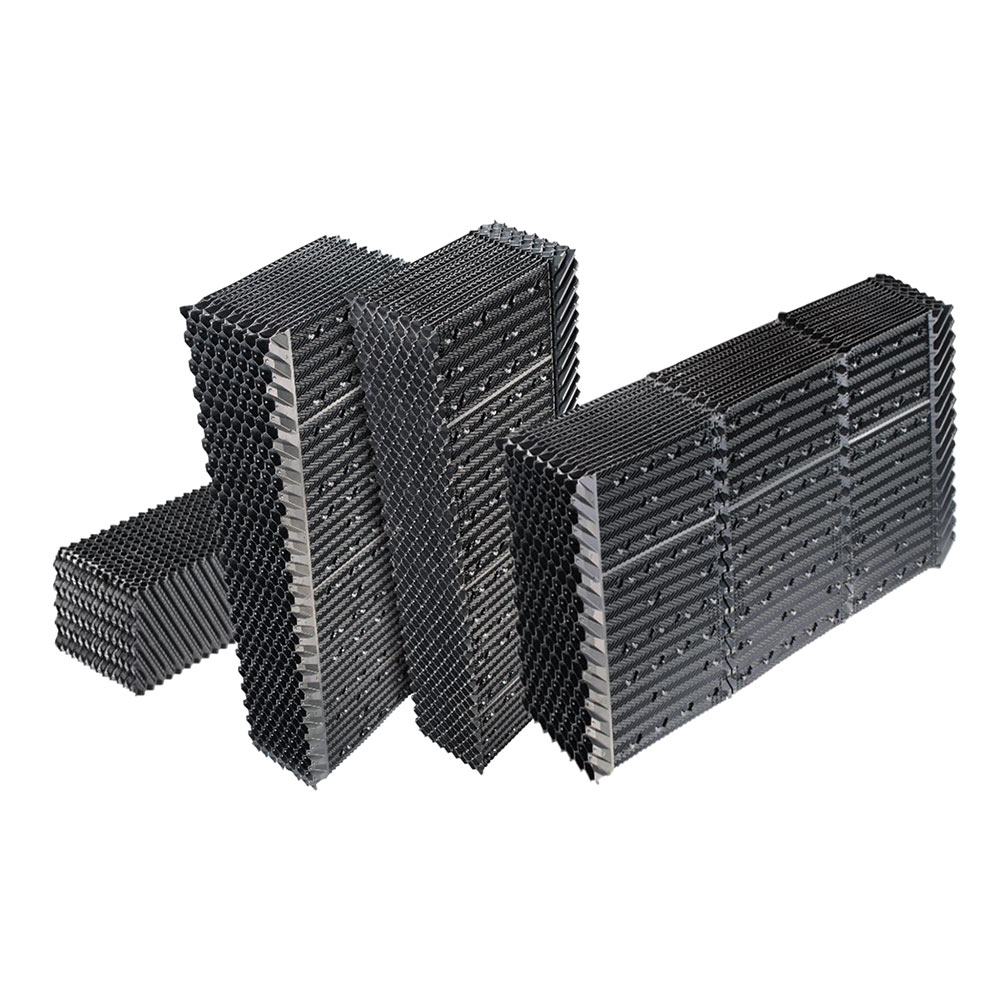

Fill media increases the contact surface between air and water, improving cooling efficiency and reducing tower size.

A properly designed cooling tower water supply ensures uniform water distribution across the fill, which is essential for stable performance.

The cooling tower water tank (basin) collects cooled water and serves as a buffer for circulation, makeup water, and blowdown control.

Compact structure, suitable for space-limited installations

Lower initial investment, resulting in a more competitive water cooling tower price

Stable airflow control, less affected by external wind conditions

Easy integration into packaged water cooling tower systems

Fan maintenance may be less convenient due to inlet location

Slightly lower thermal efficiency compared with induced draft towers

Noise concentration near the fan area may require mitigation measures

When engineers design a forced draft water cooling tower, they evaluate:

Heat load of the system

Required hot and cold water temperatures

Local climate conditions

Available cooling tower water supply

Space and budget constraints

| Parameter | Typical Value |

|---|---|

| Hot water inlet temperature | 40 °C |

| Cold water outlet temperature | 30 °C |

| Ambient dry bulb temperature | 32 °C |

| Tower type | Forced draft |

| Application | HVAC / industrial process |

Proper cooling water tower design ensures reliable operation, long service life, and optimized energy consumption.

Forced draft cooling towers are widely used in:

HVAC systems for commercial buildings

Industrial process cooling, such as plastics, chemicals, and machinery

Retrofit projects, where compact size and cost control are critical

With professional engineering and manufacturing support from Mach Cooling, customers can obtain customized solutions that balance performance and water cooling tower price.

Selecting a reliable water cooling tower manufacturer is essential for long-term performance. A qualified supplier should offer:

Proven design experience

High-quality materials and components

Flexible customization

Competitive pricing and technical support

Mach Cooling (https://www.machcooling.com/) specializes in designing and manufacturing advanced forced draft and other cooling tower types, providing dependable solutions for global customers.

A forced draft cooling tower is a practical and cost-effective option within modern water cooling tower systems. With its compact design, controlled airflow, and reliable cooling performance, it is well suited for HVAC and industrial applications.

By working with experienced manufacturers like Mach Cooling, users can achieve optimized cooling water tower design, stable cooling tower water supply, efficient cooling tower water tank management, and a competitive water cooling tower price — ensuring long-term operational success.