We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-17 Origin: Site

Cooling towers are essential components in water cooling tower systems used across industries such as HVAC, power generation, petrochemical, and manufacturing. A reliable water cooling tower ensures efficient heat rejection from systems, including cooling tower condenser water, chilled water cooling tower systems, and cooling water towers used with chillers. One key environmental factor that influences tower performance is dry bulb temperature — a concept crucial to engineers, designers, and facility managers.

In this article, we explain what dry bulb temperature is, why it matters for cooling towers (including closed loop cooling towers and water cooled towers), how it compares with other thermal metrics, and how it influences cooling tower design, cooling tower water supply, and performance expectations. We’ll also explore practical examples and include tables and visuals for clarity.

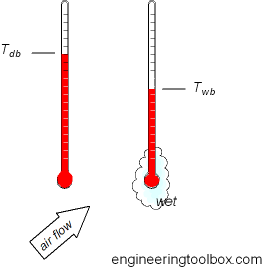

Dry bulb temperature (DBT) is the temperature of the air measured by a thermometer freely exposed to the air but shielded from direct radiation and moisture. It represents the ambient air temperature commonly reported by weather stations and is the true measure of sensible heat in the air.

This temperature does not include the influence of moisture in the air — that is covered in other metrics like wet bulb temperature (WBT) and relative humidity (RH).

| Parameter | Dry Bulb Temperature (DBT) | Wet Bulb Temperature (WBT) |

|---|---|---|

| Definition | Ambient air temperature without moisture influence | Lowest temperature achievable by evaporative cooling |

| Impact on Cooling Towers | Influences heat transfer efficiency in dry conditions | Determines the limit on how cool water can be in an evaporative cooling system |

| Measured With | Standard thermometer | Thermometer with wetted wick or sling psychrometer |

In a water cooling tower system, the ability to reject heat from process water depends on the difference between the water temperature and ambient air conditions. While wet bulb temperature is often the limiting factor for how cool circulated water can get in an open evaporative cooling tower, dry bulb temperature still plays an important role:

Air Heat Content: DBT represents the sensible heat of the air. Higher dry bulb temperatures mean hotter ambient conditions, which increase the sensible heat load on the cooling tower chilled water system.

Evaporation Rate: Even though evaporation is driven primarily by WBT, DBT helps determine the overall heat transfer rate and influences psychrometric properties of the air.

Design Conditions: In areas with high dry bulb temperatures, additional tower capacity (larger fill surface area or higher water flow) may be needed to achieve the desired cooling tower water supply temperatures.

Important: A typical cooling tower cannot cool water below the ambient wet bulb temperature, but DBT affects how quickly and efficiently that cooling occur

In cooling tower engineering, several performance factors or key metrics are affected by ambient air conditions, including DBT:

| Metric | Definition | Typical Influence from DBT |

|---|---|---|

| Range | Difference between hot water inlet and cooled water outlet | Increases with higher DBT |

| Approach | Difference between cooled water temp and wet bulb | Affected indirectly through psychrometrics |

| Heat Rejection | Total kW or BTU/hr removed from the water | Higher DBT generally reduces cooling efficiency |

| Airflow Demand | Volume of air needed through the tower | Higher DBT increases airflow requirements |

Consider a typical industrial water cooling tower used with a process chiller:

Ambient Dry Bulb Temperature: 35°C (95°F)

Design Wet Bulb Temperature: 26°C (79°F)

Water Inlet Temperature (to tower): 40°C (104°F)

Because cooling towers rely on evaporation, the limiting factor for cooling is wet bulb temperature — not dry bulb. However, the higher the dry bulb temperature, the greater the initial sensible heat load that must be overcome before evaporative cooling reaches its limit.

As a result, designers often use DBT data (from local weather records) when calculating:

Tower size and structure

Air velocity and fan requirements

Water distribution and fill design

Controls for cooling tower water tank temperature set points

| Dry Bulb (°C) | Estimated Wet Bulb (°C) | Achievable Cold Water (°C) |

|---|---|---|

| 25 | ~20 | ~25–27 |

| 30 | ~24 | ~29–31 |

| 35 | ~26 | ~32–34 |

Note: Actual results vary based on humidity and tower design efficiencies. (Illustrative based on typical performance studies.)

Mach Cooling’s product range includes various tower types — from open circuit water cooling towers to closed loop cooling towers — each responding differently to ambient DBT conditions:

Open Evaporative Towers: Depend on wet bulb temperature for cooling limits; dry bulb contributes sensibly to airflow and design stress.

Dry Cooling Towers: Rely on air alone to cool water through convection (no water evaporation). Here, dry bulb temperature directly limits performance.

Closed Loop Cooling Towers: Use a heat exchanger within the tower; DBT affects the external airflow heat rejection rates, impacting condenser and chilled water loops.

When selecting or specifying a cooling tower water supply solution, it’s critical to include DBT data in the environmental assessments. From Mach Cooling Tower’s selection guide, engineers are advised to evaluate:

Local dry bulb and wet bulb temperature profiles

Extreme temperature considerations for structural and component design

Seasonal and geographic variations to maintain performance year-round.

Dry bulb temperature is the most familiar measure of ambient air temperature and plays a key role in water cooling tower design, tower performance evaluation, and system sizing. While wet bulb temperature sets the practical limit for cooling in evaporative systems, DBT is vital for understanding sensible heat loads, overall cooling water tower design, airflow dynamics, and the integration of cooling towers into broader cooling tower condenser water and chilled water cooling tower systems.

For reliable cooling tower solutions — whether open evaporative towers, closed loop cooling towers, or custom engineered systems — trust Mach Cooling Tower, one of the experienced water cooling tower manufacturers offering optimized designs, quality components, and support across industrial and commercial applications.