We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

Understanding cooling tower range is essential for evaluating performance in any modern water cooling tower or water cooling tower system. Whether the application involves a water cooled tower, a closed loop cooling tower, a blowdown water cooling tower, or a chilled water cooling tower, knowing how cooling tower range works allows operators and engineers to optimize heat rejection, reduce energy consumption, and improve overall system reliability. This article explains the concept in detail, along with diagrams and tables, and highlights how high-quality solutions from Mach Cooling (https://www.machcooling.com/) enhance tower performance.

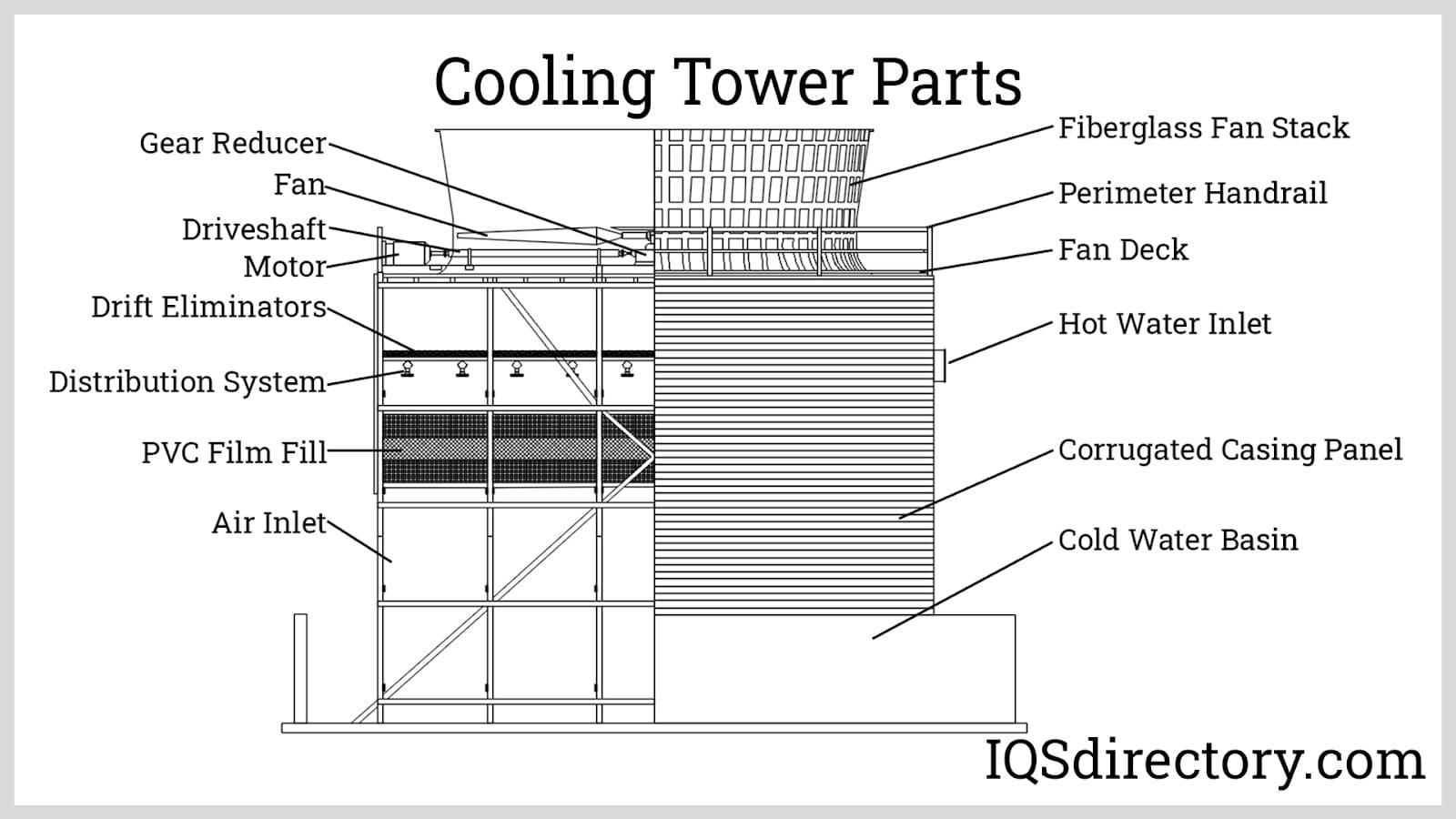

A cooling tower is a heat rejection device that removes waste heat from water by evaporative or sensible cooling. The cooled water is then recirculated within the system to absorb more heat.

Common types include:

Water cooling tower: Direct contact, open-circuit heat rejection.

Water cooled tower: General term for evaporative cooling towers.

Closed loop cooling tower: Uses a heat-exchange coil to isolate process water.

Blowdown water cooling tower: Incorporates controlled blowdown to manage water quality.

Chilled water cooling tower: Used in HVAC systems to reject heat from chilled water loops.

Regardless of tower type, cooling tower range is one of the primary performance indicators.

Cooling tower range is defined as the temperature difference between the hot water entering the tower and the cold water leaving it.

[

\textbf{Cooling Tower Range} = T_{\text{hot water}} - T_{\text{cold water}}

]

T_hot water → Temperature of water entering the cooling tower

T_cold water → Temperature of water leaving the cooling tower

The larger the range, the more heat the tower is successfully rejecting.

Range, approach, and efficiency are three closely related performance metrics.

| Parameter | Meaning | Formula |

|---|---|---|

| Range | Water temperature drop through the tower | (T_{\text{hot}} - T_{\text{cold}}) |

| Approach | How close cold water gets to wet-bulb temperature | (T_{\text{cold}} - T_{\text{wet-bulb}}) |

| Efficiency | Relative cooling performance | (\frac{\text{Range}}{\text{Range} + \text{Approach}}\times100%) |

| Item | Value |

|---|---|

| Hot Water Temperature | 38 °C |

| Cold Water Temperature | 28 °C |

| Wet-Bulb Temperature | 22 °C |

| Range | 10 °C |

| Approach | 6 °C |

| Efficiency | 62.5 % |

Different cooling tower types deliver different ranges due to design differences.

| Cooling Tower Type | Typical Range | Notes |

|---|---|---|

| Water Cooling Tower | 5–12 °C | Standard open-circuit cooling |

| Water Cooled Tower | 6–12 °C | High heat rejection efficiency |

| Closed Loop Cooling Tower | 4–10 °C | Coil heat exchange limits range |

| Blowdown Water Cooling Tower | 5–11 °C | Maintains range via water quality control |

| Chilled Water Cooling Tower | 7–13 °C | Works with chillers; load-dependent |

Higher inlet temperatures increase potential range because more heat can be removed.

The cooling tower fan plays a major role. Higher airflow increases evaporation and therefore increases range.

Lower water flow extends the contact time with air, increasing possible range, though extremely low flow can reduce tower performance.

High-surface-area fill and uniform water distribution enhance heat transfer.

Higher wet-bulb temperatures limit achievable cooling, reducing range.

Open-loop water cooling tower systems achieve large ranges due to direct water–air contact. Mach Cooling’s optimized fill and aerodynamic design help maximize range.

Induced-draft systems use high-efficiency fans to improve airflow and maintain consistent cooling range even under part load.

Ranges are slightly smaller due to the heat exchanger coil, but reliability and water cleanliness are improved.

Controlled blowdown prevents scale, maintaining strong heat-transfer capability and stabilizing range.

Good range control improves chiller efficiency and reduces energy consumption in commercial HVAC plants.

Improved air movement increases evaporation, raising cooling capability.

More surface area means better heat exchange between water and air.

Uniform spray patterns prevent dry zones that reduce cooling.

Scaling and fouling greatly reduce range; proper chemical treatment and blowdown control are essential.

Smart monitoring helps maintain optimum range and system performance.

High-performance cooling towers from Mach Cooling (https://www.machcooling.com/) achieve excellent cooling ranges due to:

Advanced aerodynamic design

High-efficiency cooling tower fans

Large-surface-area fill media

Stable performance across water cooling tower, closed loop cooling tower, and chilled water cooling tower applications

Strong water quality management for blowdown water cooling tower systems

Mach Cooling provides reliable solutions that support higher range, better efficiency, and longer equipment life.

Cooling tower range is a core indicator of how effectively a cooling tower removes heat from circulating water. It represents the temperature difference between hot water entering and cold water leaving the tower. Understanding cooling tower range — along with approach and efficiency — helps engineers design, size, and operate systems more effectively.

Whether working with a water cooling tower, a water cooled tower, a chilled water cooling tower, a closed loop cooling tower, or a blowdown water cooling tower, optimizing range improves:

Cooling performance

Energy efficiency

Chiller stability

Overall system reliability

With expert engineering and high-quality components from Mach Cooling, achieving superior cooling tower range becomes easier and more cost-effective.