We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

Cooling tower fill material is one of the most critical components inside a water cooling tower or water cooling tower system. Whether the system is small-scale HVAC or large industrial, the fill material — also called cooling tower water fill or infill media — directly affects heat transfer efficiency, water distribution, and overall system performance. Proper fill material enables maximum contact between water and air, accelerating evaporative cooling and supporting lower water temperatures. This article explores what cooling tower fill material is, the common materials used, how it works, types and design considerations, and how manufacturers like Mach Cooling (https://www.machcooling.com/) support optimized fill solutions.

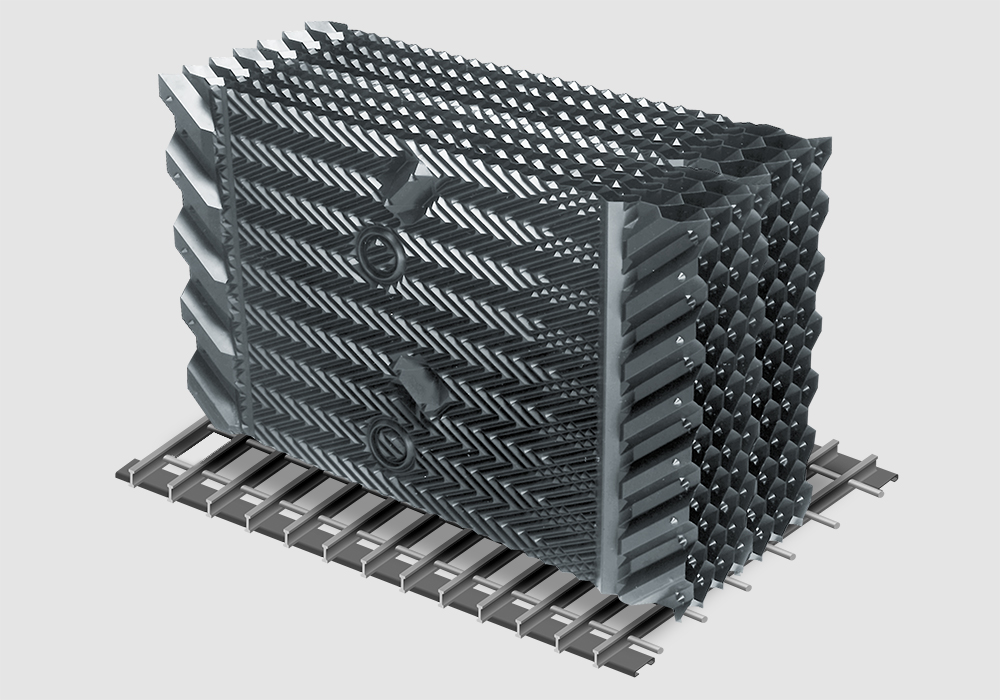

Cooling tower fill is the engineered medium installed inside the cooling tower where heat exchange actually happens. It increases the surface area of falling water and slows its descent, allowing ambient air — drawn by the fan or natural draft — to contact a larger water surface. This improves evaporation and boosts thermal performance.

The primary role of fill is to:

Break water into thin films or droplets

Extend the air–water contact time

Increase the surface area available for evaporation

Promote uniform water distribution

As water spreads over the fill surfaces, heat is transferred from water to air; more surface area and contact time directly improve cooling efficiency.

Cooling tower fill material is typically manufactured from corrosion-resistant plastics or engineered composites. While older towers sometimes used wood, modern designs almost exclusively use plastics due to durability and efficiency advantages.

PVC is the most widely used fill material in cooling towers due to:

Cost-effectiveness

Good corrosion and chemical resistance

Lightweight and easy fabrication

Excellent wetting properties for film fill designs

PVC fill is a standard choice for many industrial and HVAC systems unless very high water temperature conditions exist.

Polypropylene fill provides:

Higher temperature tolerance compared to PVC

Better resistance to harsh chemicals

Strong mechanical stability

PP fill is often preferred in towers handling hotter water or exposure to more aggressive water chemistries within a water cooling tower system.

CPVC (Chlorinated PVC) and other engineered plastics can withstand even greater thermal loads and chemical exposure, making them suitable for specialized industrial cooling towers where operating temperatures exceed PVC’s range.

Advanced composites, blends like PVC/PP composite, and HDPE (High-Density Polyethylene) fill materials offer balanced mechanical strength, chemical resistance, and durability when applications demand both higher performance and long service life.

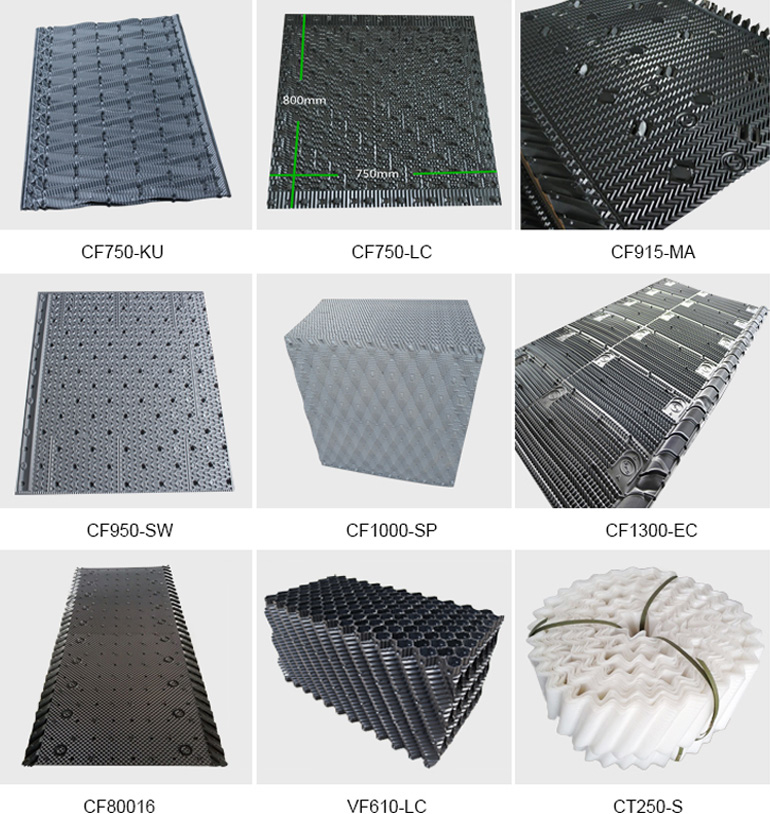

Fill materials come in different structural configurations, each suited to specific cooling scenarios:

| Fill Type | Description | Typical Use |

|---|---|---|

| Film Fill | Thin, corrugated sheets forming large wetted surface | High efficiency, most common |

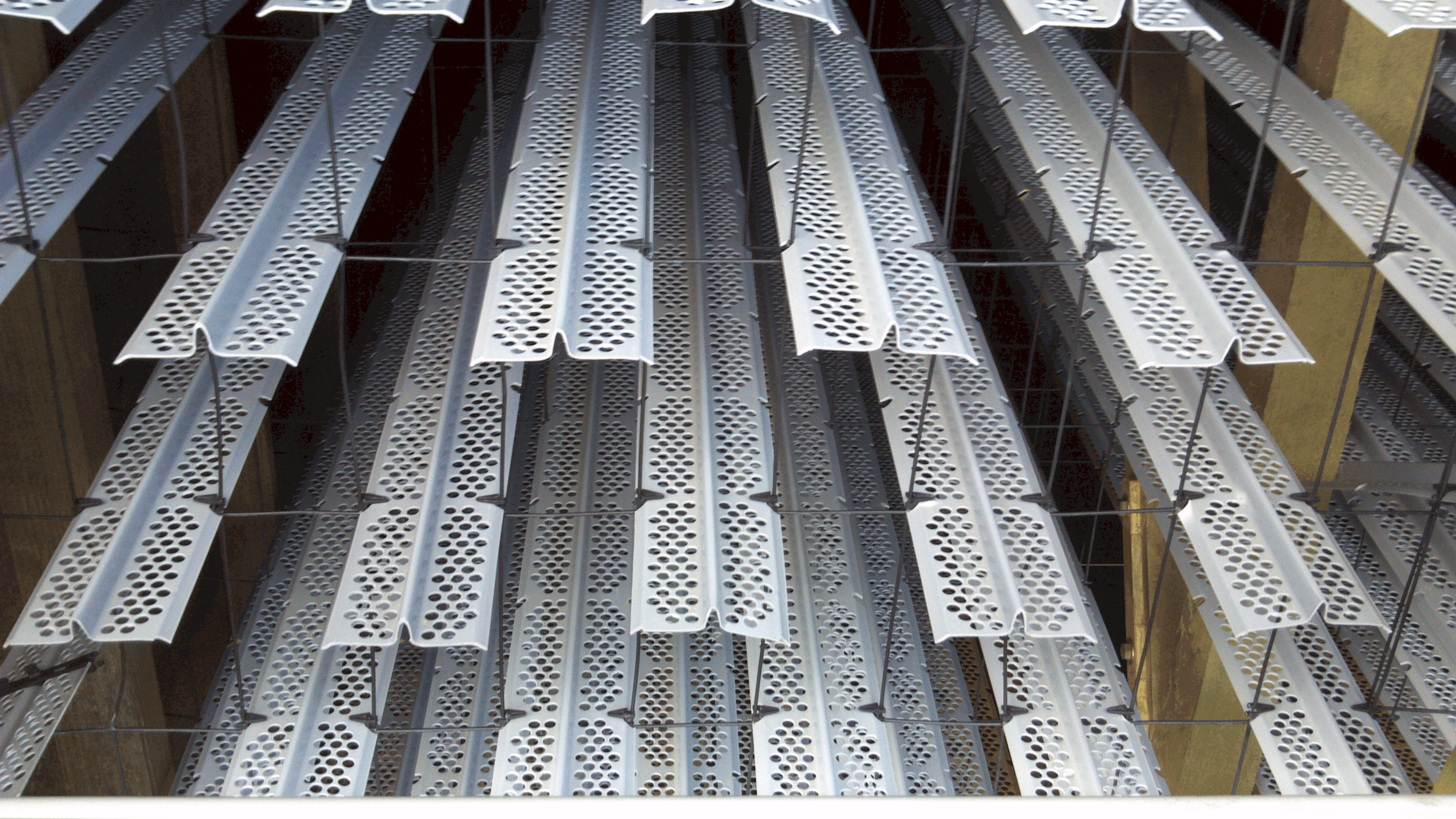

| Splash Fill | Blocks or bars that break water into droplets | Better for dirty or sediment-prone water |

| Honeycomb/Oblique Fills | Enhanced geometry for extra surface area | Optimized for high heat loads |

Film fill creates a continuous water film that maximizes air–water interaction, while splash fill mechanically breaks water into droplets for reliable cooling in challenging water conditions.

Film fills consist of thin, vertically oriented sheets that distribute water into a film, spreading it over a large area. This type is highly efficient in creating intimate contact between the cooling water and air.

Splash fill uses a series of slats or bars. Water drops hit these surfaces and splashes into smaller droplets, increasing the wet surface area and improving evaporation, which is especially useful when water contains particulate matter.

Quality fill materials and configurations significantly improve heat transfer efficiency — reducing approach temperatures, lowering outlet water temperature, and enhancing the overall performance of a water cooling tower.

Visualizing how fill works: as warm water from the system travels downward, it spreads over the fill, while air flows upward (natural or fan-driven). This counterflow or crossflow maximizes heat exchange before the water is collected in the basin and recirculated.

Fill materials must withstand continuous exposure to water, possible additives like cooling tower water treatment chemicals, and biofilm conditions. Materials like PVC, PP, and composites maintain integrity longer and resist degradation.

Different plastics vary in thermal stability:

PVC: up to ~65 °C

PP: up to ~90 °C

CPVC: up to ~100 °C or more

These differences influence material selection based on your system’s circulating water temperature and design load.

Fill media exposed to sunlight and environmental conditions should resist UV degradation and maintain structural integrity — another reason plastics dominate over legacy materials like wood.

In open water cooling towers, fill material enables large surface interaction between warmer water and air, helping cool the water before it returns to the process loop. This is critical for maintaining temperature targets across industrial and HVAC applications.

Within a complete water cooling tower system, fill packs must be designed for compatibility with water distribution systems, drift eliminators, and spray nozzles to ensure uniform water spread over the fill. (sintafrp.com)

Although closed loop cooling towers use coils, engineered fill materials still play a role in heat rejection when water or fluid passes over the fill in indirect contact. Optimized fill helps ensure consistent thermal performance even in closed applications.

| Material | Temperature Limit | Corrosion Resistance | Best Application |

|---|---|---|---|

| PVC | ~65 °C | High | Standard towers |

| PP | ~90 °C | Very High | Hot water or chemical environments |

| CPVC | ~100 °C | Excellent | Heavy industrial, high heat |

| HDPE | Varies | Excellent | Outdoor/UV exposure |

| Composite PVC/PP | Varies | Very Good | Balanced performance |

Deposits, scale, and biofilm on the fill surface reduce heat transfer efficiency. Regular inspection and cleaning help maintain optimal performance and minimize uneven flow paths that can reduce cooling tower water fill effectiveness.

Fill materials should be compatible with cooling tower water treatment chemicals to prevent premature degradation and maintain structural integrity. Proper treatment reduces buildup and prolongs fill life.

Mach Cooling (https://www.machcooling.com/) provides engineered cooling tower solutions that incorporate:

Optimized cooling tower water fill materials

High-efficiency designs for enhanced heat transfer

Support for full water cooling tower systems

Integration with water treatment planning

Quality fill materials help reduce water usage, improve cooling performance, and enhance system reliability — benefits that align with Mach Cooling’s focus on durability and performance.

Cooling tower fill material is the vital component that enables efficient heat rejection in a water cooling tower. By expanding the surface area for water–air contact, quality fill maximizes evaporative cooling, lowers water discharge temperatures, and supports operational efficiency. Materials like PVC, PP, and CPVC provide chemical resistance and thermal stability suited to different applications, while design options such as film and splash fill tailor performance to water quality and heat load conditions.

Selecting the right fill — designed to match your cooling demands and environmental conditions — makes a measurable difference in performance and long-term cost savings. With industry-grade solutions from manufacturers like Mach Cooling, your cooling tower can achieve higher thermal efficiency, extended service life, and better compatibility with cooling tower water treatment chemicals and full system design requirements.