We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

Cooling tower efficiency refers to how effectively a cooling tower reduces the temperature of circulating water within a water cooling tower system. It measures how close the cooled water temperature approaches the wet-bulb temperature of the air. In simple terms, higher cooling tower efficiency means better heat rejection, lower energy consumption, and more stable system operation.

Cooling tower efficiency is critical in all cooling tower types—including water cooled tower, closed loop cooling tower, blowdown water cooling tower, chilled water cooling tower, and condenser water cooling tower systems. Manufacturers like Mach Cooling (https://www.machcooling.com/) design towers, components, and cooling tower fans specifically to maximize efficiency and minimize operating cost.

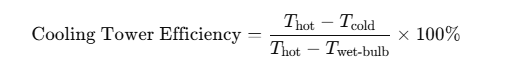

Cooling tower efficiency is usually expressed as:

Where:

T_hot = temperature of water entering the tower

T_cold = temperature of water leaving the tower

T_wet-bulb = ambient wet-bulb temperature

A cooling tower relies on evaporation. The lowest temperature water can reach under real conditions is the atmospheric wet-bulb temperature. Therefore, cooling tower efficiency depends largely on air conditions, water flow, heat load, and fan performance.

Most modern towers achieve 65%–80% efficiency, while high-performance designs from manufacturers such as Mach Cooling can reach up to 85%+ under optimized conditions.

The cooling tower fan drives all airflow, making it one of the strongest influencers of efficiency.

A high-quality fan improves:

Air velocity through fill

Evaporation rate

Water–air heat exchange

System stability under varying loads

Mach Cooling provides optimized aerodynamic fans that reduce energy use while maximizing airflow.

Fill enhances contact between air and water. Efficient towers use high-surface-area PVC or PP fill to improve evaporation.

Uniform water spraying across the fill avoids dry spots and increases thermal performance.

Clean, unobstructed inlets ensure proper airflow, while drift eliminators reduce water loss.

These open-loop systems rely heavily on evaporation. Efficiency is significantly influenced by:

Fill surface area

Fan airflow

Makeup water quality

Blowdown frequency

In these systems, process fluid runs inside coils. Efficiency is determined by:

Coil cleanliness

Airflow across coil surfaces

Spray system performance

Blowdown frequency affects cycles of concentration (COC).

Too much blowdown → wasted water

Too little blowdown → scaling → reduced efficiency

Used with chillers, these require:

Stable return temperatures

Variable-speed fan control

Optimized tower/chiller matching

These towers serve HVAC condensers. Efficiency directly impacts chiller COP (Coefficient of Performance).

Lower condenser water temperature → lower energy consumption.

| Tower Type | Typical Efficiency | Notes |

|---|---|---|

| Water Cooling Tower | 65–80% | Most influenced by ambient wet-bulb temperature |

| Closed Loop Cooling Tower | 55–70% | Coil heat exchange limits max approach |

| Blowdown Water Cooling Tower | 60–80% | Efficiency improves with good water control |

| Chilled Water Cooling Tower | 70–85% | VFD fans greatly improve part-load efficiency |

| Condenser Water Cooling Tower | 65–85% | Directly affects chiller performance |

Using VFD (variable-frequency drive) allows automatic fan speed adjustment, saving energy while maintaining water temperature.

Scaling and biological fouling reduce contact area and efficiency.

Especially in blowdown water cooling towers, proper COC control avoids:

Scale

Corrosion

Algae growth

Too low → insufficient heat transfer

Too high → poor contact time

Air inlets, drift eliminators, and nozzles must be kept clean.

Mach Cooling (https://www.machcooling.com/) designs equipment specifically to maximize cooling tower efficiency through:

High-efficiency cooling tower fans

Advanced fill media

Superior water distribution systems

Low-noise, low-energy motors

Strong FRP body panels for durability

Precise engineering for both HVAC and industrial applications

Their solutions support all system types, including water cooling tower, closed loop cooling tower, chilled water cooling tower, and condenser water cooling tower projects worldwide.

Cooling tower efficiency is a direct measure of how effectively a tower reduces water temperature relative to the atmospheric wet-bulb limit.

It is influenced by airflow, fan performance, fill media, water distribution, and water chemistry.

For any water cooling tower system—whether industrial, process-based, or HVAC—high efficiency leads to:

Lower operating costs

Better equipment protection

Higher chiller performance

Extended system lifespan

Manufacturers such as Mach Cooling provide optimized designs and components to ensure maximum efficiency in water cooled towers, closed loop towers, blowdown systems, chilled water cooling towers, and condenser water cooling towers.