We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

Cooling towers are the backbone of industrial and HVAC systems, keeping water at optimal temperatures for maximum efficiency. One key concept that often confuses operators and engineers is approach temperature. Understanding it can save energy, optimize performance, and extend equipment life. Let’s break it down step by step.

Cooling towers handle thousands of gallons of water daily. Any inefficiency in cooling directly affects system performance and energy consumption. Approach temperature tells us how effectively a cooling tower cools water relative to the surrounding air, helping operators identify performance gaps and optimize operations.

Cooling towers remove excess heat from water by transferring it to the atmosphere, primarily through evaporation. Hot water from the condenser or process equipment enters the tower, spreads over fill media, and is cooled by airflow. The cooled water then returns to the system.

Important parameters include:

Hot water inlet temperature

Cold water outlet temperature

Ambient wet-bulb temperature

Approach temperature

Approach temperature is a key efficiency indicator that shows how close the cooled water gets to the ambient wet-bulb temperature.

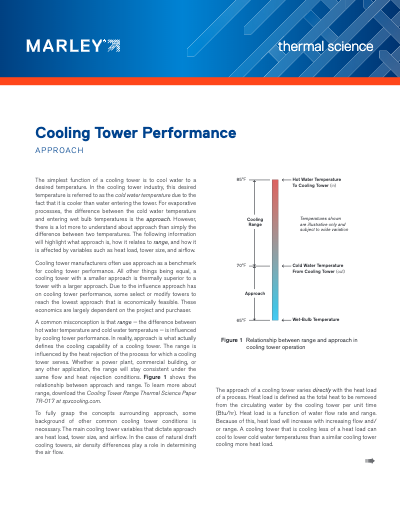

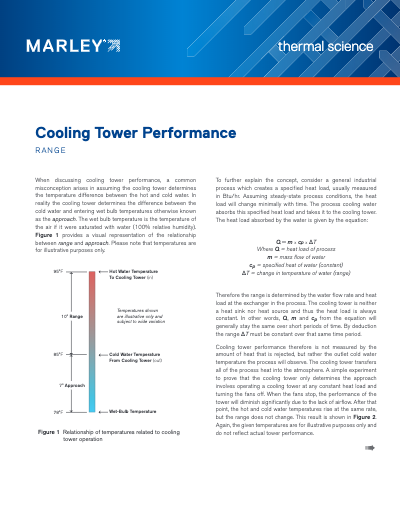

Approach temperature is the difference between the cooled water temperature leaving the tower and the ambient wet-bulb temperature. A lower approach temperature means the tower is performing closer to its theoretical maximum efficiency.

Measure the cold water temperature leaving the tower and the ambient wet-bulb temperature. The formula is:

Approach Temperature (°C) = Cold Water Temperature Out – Ambient Wet-Bulb Temperature

Smaller approach temperatures indicate higher cooling efficiency. Efficient cooling towers reduce energy costs and ensure optimal system operation.

The wet-bulb temperature represents the lowest water temperature theoretically achievable through evaporation. Approach temperature shows how close the tower comes to this limit under actual conditions.

Natural draft towers rely on buoyancy-driven airflow, while mechanical draft towers use fans. Mechanical draft towers usually achieve lower approach temperatures due to better airflow control.

Uniform water distribution maximizes contact with air and fill media, reducing approach temperature. Poor distribution leads to higher approach and lower efficiency.

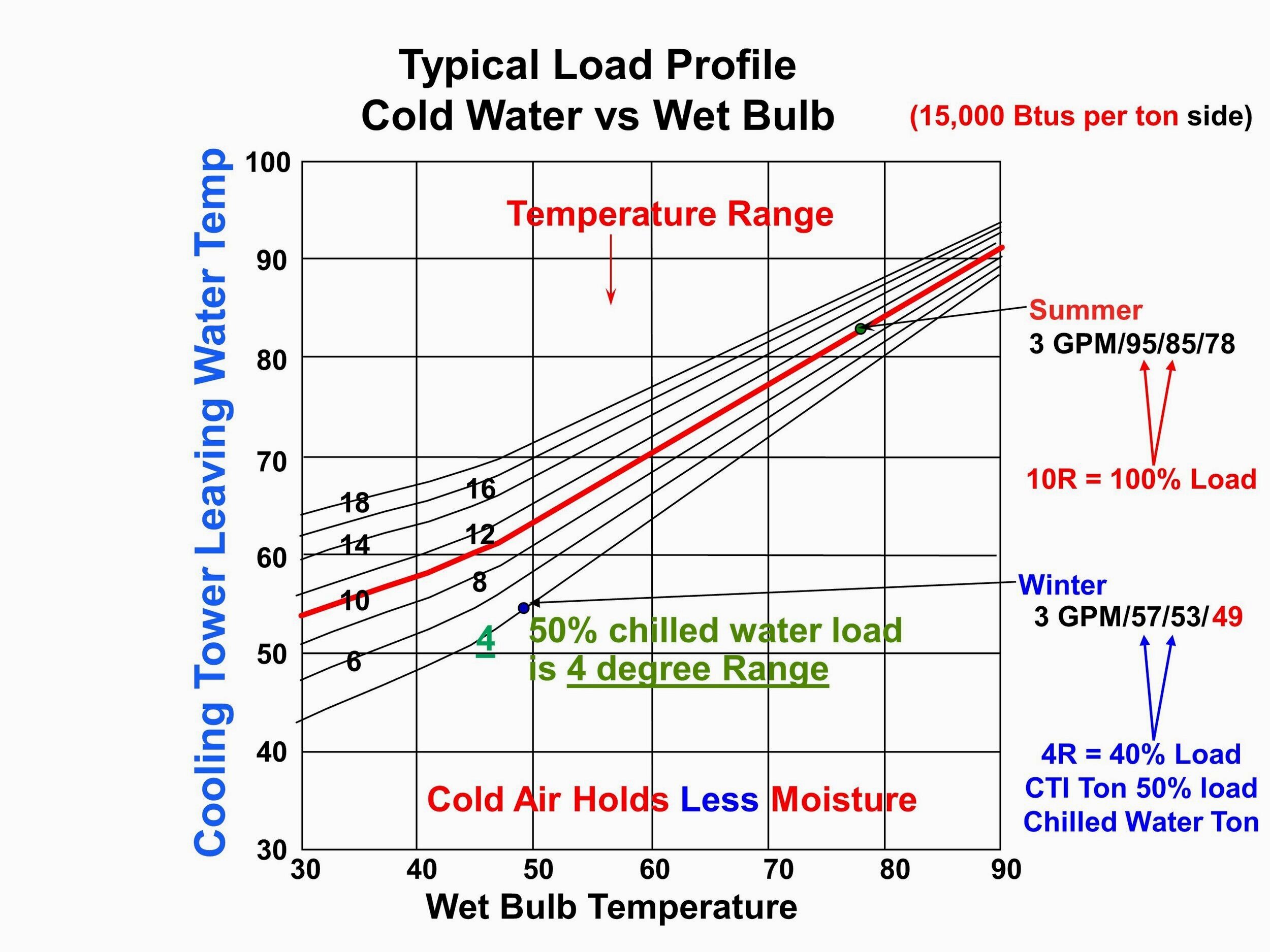

Higher airflow improves heat transfer. Hot and humid ambient conditions make it harder to achieve low approach temperatures.

Advanced fill media increases water-air contact area, improving evaporation and lowering approach temperature.

Approach (°C) = Cold Water Temperature – Wet-Bulb Temperature

Example: Cold water 30°C, ambient wet-bulb 25°C → Approach = 5°C.

Typical approach temperatures:

5–7°C for large industrial towers

2–4°C for high-efficiency HVAC systems

Lower approach requires better design and maintenance.

Industrial towers: 4–7°C

HVAC towers: 2–5°C

Performance depends on tower size, airflow, water flow, and fill design.

Clean basins, nozzles, and fill media regularly. Scaling and fouling increase approach temperature.

Optimized fill increases water-air contact, reducing approach temperature and improving heat transfer.

Adjust fans and pumps for uniform water distribution and optimal airflow to achieve lower approach temperature.

Ignoring ambient wet-bulb conditions

Uneven water distribution

Neglecting fill maintenance

Incorrect tower sizing

Addressing these prevents poor tower performance.

Approach temperature informs tower sizing, pump selection, and process cooling requirements, making it crucial for engineers during both design and operation.

Mach Cooling (https://www.machcooling.com/) designs high-efficiency cooling towers that achieve low approach temperatures through:

Advanced fill media

Optimized airflow patterns

Durable, corrosion-resistant construction

Their solutions help industries maintain ideal water temperatures and improve system efficiency reliably.

Many industrial plants achieve approach temperatures of 3–5°C using Mach Cooling towers, resulting in:

Reduced pump energy use

Lower chemical treatment needs

Higher process efficiency

Smart sensors and automated monitoring for real-time approach temperature

AI-based control of water and airflow

Hybrid fill designs to minimize approach temperature

These innovations aim to maximize efficiency while reducing operating costs.

Approach temperature is more than a number—it’s a key indicator of cooling tower efficiency. Understanding, monitoring, and optimizing approach temperature ensures better system performance, energy savings, and longer equipment life. Choosing advanced solutions from Mach Cooling helps operators achieve lower approach temperatures and maximize cooling tower efficiency sustainably.