We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

Understanding water quality is critical for the efficiency and longevity of any water cooling tower system. One of the most important parameters in cooling-water chemistry is conductivity. This article will explain what conductivity is, why it matters in cooling towers (including water cooling tower, water cooled tower, closed loop cooling tower, blowdown water cooling tower, and chilled water cooling tower systems), how it’s measured, and best practices for managing it.

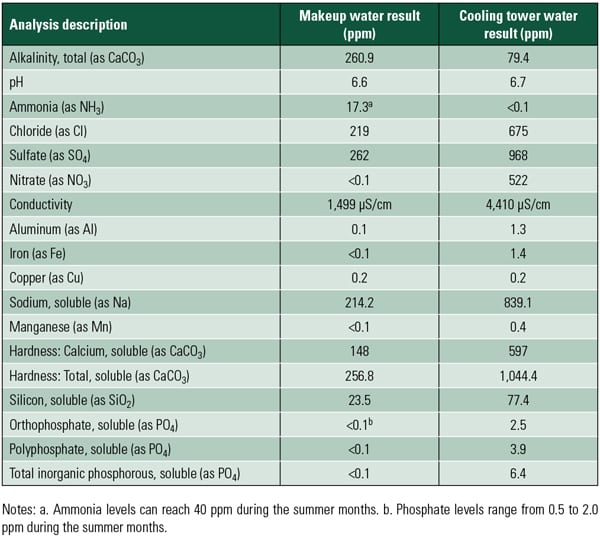

Conductivity is a measure of how well water conducts electrical current. Pure water is a poor conductor, but when dissolved ions (such as salt and minerals) are present, conductivity increases. In the context of cooling towers, conductivity reflects the concentration of dissolved solids in the water.

Conductivity is a measure of how well water conducts electrical current. Pure water is a poor conductor, but when dissolved ions (such as salt and minerals) are present, conductivity increases. In the context of cooling towers, conductivity reflects the concentration of dissolved solids in the water.

Cooling towers are designed to remove heat from industrial processes or HVAC systems by evaporating water. As water evaporates, dissolved minerals stay behind, increasing the conductivity.

High conductivity can lead to:

Scale formation: Minerals precipitate and form insulating layers.

Corrosion: Elevated ion levels accelerate metal degradation.

Reduced heat transfer: Dirty heat exchange surfaces lower efficiency.

Increased maintenance costs: More frequent cleaning and downtime.

These challenges are relevant across all water cooling tower systems, including water cooled towers and closed loop cooling towers.

In a water cooling tower or water cooled tower, large volumes of water evaporate to reject heat. With ongoing evaporation, dissolved solids concentrate, so conductivity must be monitored to maintain performance and prevent scaling.

In closed loop cooling tower systems, water flows through a closed circuit and exchanges heat with the tower water. Conductivity monitoring here protects the internal loop from contamination and preserves heat exchanger integrity.

Blowdown water cooling towers control conductivity by discharging (blowing down) a portion of the circulating water to remove excess dissolved solids, replacing it with fresh makeup water.

This process lowers conductivity and minimizes corrosion and scaling.

A chilled water cooling tower supports chilled water loops for air conditioning systems. Conductivity control helps maintain treatment chemicals in balance, reducing microbial growth and equipment degradation.

Conductivity is typically measured using a conductivity meter or probe installed in the cooling tower water loop.

Common units:

| Unit | Meaning |

|---|---|

| µS/cm | Microsiemens per centimeter |

| mS/cm | Millisiemens per centimeter (1000 µS/cm) |

| PPM (approx.) | Approximation related to total dissolved solids |

Measurements should be taken regularly, often at key points in the system, especially after blowdown events.

| Cooling Tower Type | Target Conductivity (µS/cm) | Notes |

|---|---|---|

| Open Water Cooling Tower | 1200–2500 | Depends on makeup water quality |

| Closed Loop System | 500–1500 | Tighter control due to sensitive components |

| Blowdown Systems | 1000–2000 | Managed with scheduled blowdowns |

| Chilled Water Systems | 800–1800 | Balance between scale control and chemical costs |

These ranges are general guidelines. Actual targets depend on system design, makeup water quality, and treatment protocols.

Controlling conductivity often requires periodic blowdown for blowdown water cooling towers to remove concentrated solids.

Chemical treatment helps sequester minerals and prevent scale and corrosion. Typical additions include:

Scale inhibitors

Corrosion inhibitors

Biocides

Choosing better-quality makeup water (lower mineral content) reduces conductivity buildup.

Modern systems, like those supported by Mach Cooling, use electronic controllers to maintain conductivity within target ranges, saving resources and protecting equipment performance.

flowchart TD

A[Start: Cooling Tower Online] --> B{Measure Conductivity}

B -- Below Target --> A

B -- Above Target --> C[Initiate Blowdown]

C --> D[Add Makeup Water]

D --> E[Adjust Chemical Feed]

E --> B As a trusted provider of industrial cooling solutions, Mach Cooling (https://www.machcooling.com/) offers complete support for water cooling tower systems, including:

Conductivity monitoring solutions

Blowdown and water treatment optimization

Turnkey water cooled tower installations

Support for closed loop cooling tower and chilled water cooling tower applications

Their expert engineers help ensure optimal water quality, peak efficiency, and long equipment life.

Conductivity is a simple measurement with complex implications in cooling tower operation. Whether you’re running a water cooling tower, managing blowdown water cooling tower processes, or optimizing a closed loop cooling tower or chilled water cooling tower, understanding and controlling conductivity is crucial for performance and longevity.

By implementing proper monitoring, treatment, and management strategies—especially with partner expertise from companies like Mach Cooling—you can ensure reliable, efficient cooling for your industrial or commercial applications.