We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-27 Origin: Site

When people talk about cooling towers, they usually focus on fans, fill media, or water treatment. But hidden in the piping network is a group of components that quietly decide whether the entire system runs smoothly or turns into a headache—cooling tower valves. Think of them as the nervous system of a cooling tower. They don’t generate power or remove heat directly, but without them, nothing works the way it should.

In this complete guide, we’ll break down what a cooling tower valve is, how it works, why it matters, and how the right valve selection—especially from a reliable manufacturer like Mach Cooling—can make a real difference in efficiency, water management, and long-term reliability.

A cooling tower moves large volumes of water every single day. That water must be added, circulated, controlled, and sometimes discharged. Cooling tower valves make all of this possible. Without valves, you’d have no control over water levels, no way to isolate equipment, and no method to protect the system from scaling or overflow.

In short, cooling tower valves don’t just support the system—they control it.

Let’s start with a clear, no-nonsense definition.

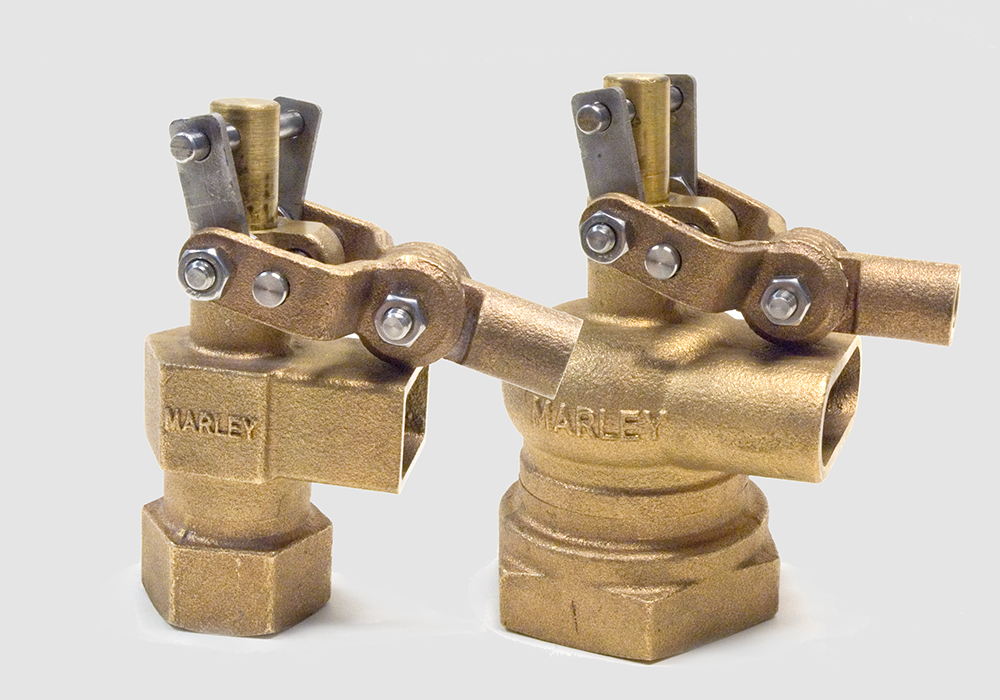

A cooling tower valve is a mechanical device used to regulate, control, isolate, or stop the flow of water within a cooling tower system. These valves manage make-up water, blowdown, circulation, drainage, and isolation for maintenance.

Imagine driving a car with no brakes or steering wheel. That’s what a cooling tower looks like without valves. Valves give operators control. They protect equipment, stabilize performance, and help maintain water quality.

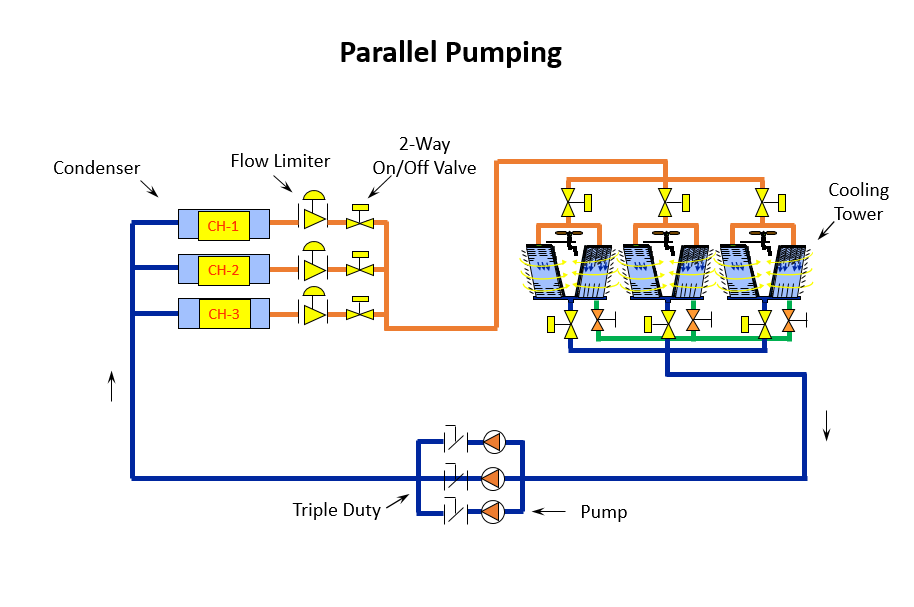

Cooling tower valves operate by opening, closing, or partially restricting a flow path inside the valve body. Some are simple manual valves, while others are automated and respond to sensors.

When a valve opens wider, more water flows. When it closes, flow is reduced or stopped. It sounds basic—but in cooling towers, precise flow control can mean the difference between stable operation and constant troubleshooting.

Correct valve operation ensures:

Stable basin water levels

Proper flow distribution over fill

Controlled blowdown and water quality

Efficient pump operation

Poor valve control leads to overflow, scaling, uneven cooling, and wasted energy.

Different cooling tower functions require different valve types. Let’s look at the most common ones.

The make-up water valve automatically adds fresh water to the cooling tower to replace losses from evaporation, drift, and blowdown. It works much like a float valve in a toilet tank—but designed for industrial conditions.

The blowdown valve removes a portion of circulating water to control dissolved solids. Without proper blowdown, minerals concentrate and cause scaling, corrosion, and fouling.

Isolation valves allow operators to shut off sections of the cooling tower system for maintenance or repairs without stopping the entire operation. These valves are essential for safe and efficient servicing.

Flow control valves regulate water flow to ensure optimal heat transfer. Too much flow wastes pumping energy; too little flow reduces cooling performance.

Balancing valves distribute water evenly across multiple cooling tower cells or branches. They prevent hot spots and uneven cooling, especially in large systems.

Valve material selection directly affects durability and maintenance needs.

PVC and UPVC valves are lightweight, corrosion-resistant, and cost-effective. They are commonly used for make-up water and blowdown lines where pressure and temperature are moderate.

Stainless steel valves offer excellent strength and corrosion resistance, making them ideal for high-temperature or high-pressure applications and long service life.

These traditional materials are still used in some systems but require proper water treatment to prevent corrosion and premature failure.

Cooling tower valves are strategically placed throughout the system.

Make-up water valves control the incoming water level and prevent overflow or dry operation.

Blowdown valves regulate discharge to maintain water chemistry and cycles of concentration.

Isolation and flow control valves manage circulation and allow sections of the system to be serviced safely.

Water management is one of the biggest challenges in cooling tower operation—and valves play a central role.

Proper valve control prevents pump cavitation, overflow, and low-water shutdowns.

Automated blowdown valves help maintain stable water chemistry, reducing chemical consumption and scaling risk.

Efficient valve control reduces pumping power, stabilizes heat transfer, and minimizes unnecessary water loss. Small improvements in valve performance can translate into significant energy savings over time.

Like any mechanical component, valves can fail if neglected.

Leaks waste water, chemicals, and energy. They’re often caused by worn seals, corrosion, or improper installation.

Mineral deposits can cause valves to stick or respond slowly, reducing control accuracy.

Oversized or undersized valves lead to unstable flow control and inefficient operation.

Choosing the right valve isn’t guesswork—it’s engineering.

Valve ratings must match actual operating conditions to ensure safety and longevity.

Automated valves improve precision and reduce labor, especially in large or critical cooling tower systems.

Good maintenance keeps valves reliable and responsive.

Regularly inspect valves for leaks, corrosion, and smooth operation.

Clean or replace valves during scheduled shutdowns to avoid emergency failures.

Improper valve operation can cause flooding, pressure surges, or equipment damage. Always follow lockout/tagout procedures and safety protocols during maintenance.

High-quality valves ensure accurate control, long service life, and stable operation. Cutting corners on valve quality often leads to higher long-term costs.

Mach Cooling (https://www.machcooling.com/) integrates carefully selected, high-quality valves into its cooling tower systems. By focusing on corrosion resistance, precise flow control, and durability, Mach Cooling ensures reliable water management, efficient operation, and reduced maintenance for customers worldwide.

Cooling tower valves may not grab attention, but they are absolutely essential. They regulate flow, protect equipment, save energy, and keep the entire cooling system balanced. When paired with a well-engineered cooling tower from Mach Cooling, the right valves transform a basic cooling setup into a dependable, efficient, and long-lasting solution.