We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-23 Origin: Site

An in-depth guide with H1–H4 structure, images, tables, and insights — featuring solutions from Mach Cooling

Cooling tower systems are vital pieces of infrastructure across many industries — from large power plants and chemical facilities to commercial HVAC systems and manufacturing plants. These systems remove waste heat from process water by transferring it to the atmosphere, keeping equipment safe and operational. A well-designed cooling tower system improves energy efficiency, lowers costs, and supports continuous production.

In this article, you’ll learn what a cooling tower system is, how it works, its main components, types, performance factors, maintenance, and how manufacturers like Mach Cooling help deliver reliable, efficient systems.

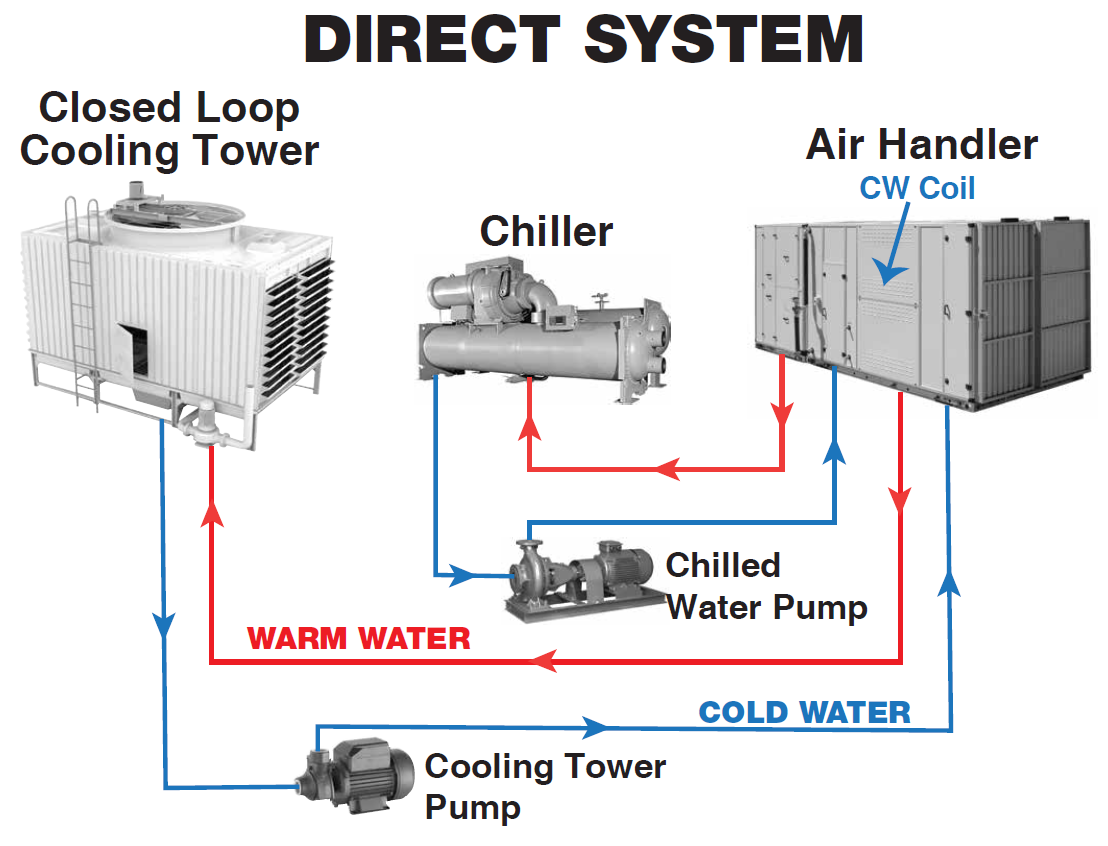

A cooling tower system is a complete set of equipment designed to remove heat from a facility by cooling warm process water and returning it to the system for reuse. The system uses evaporative cooling — where a portion of water evaporates, absorbing heat from the remaining water — to lower temperatures effectively and efficiently.

At its core, a cooling tower system circulates water in a closed loop:

Warm water from industrial equipment enters the tower.

Air passes through the water, enabling evaporation and heat transfer.

Cooled water collects and returns to the heat-producing equipment.

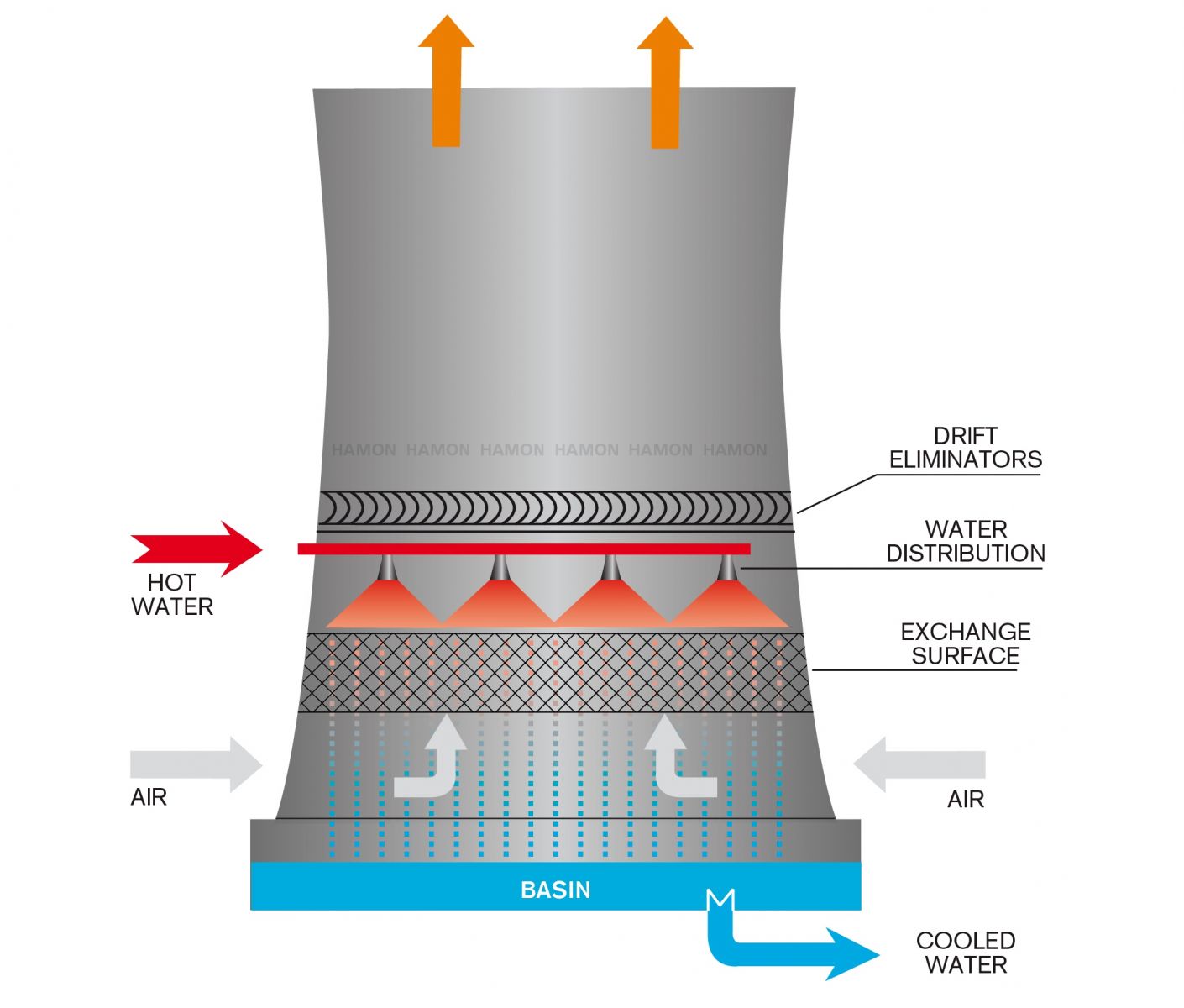

The basic operating principle of a cooling tower system involves heat transfer from water to air. Here’s how it works:

Warm Water Entry – Hot water from chillers, condensers, or industrial processes is pumped into the cooling tower.

Water Distribution – Water is sprayed or directed over the fill media, which increases the surface area for water–air interaction.

Air Flow Movement – Air is drawn through the tower using fans (mechanical draft) or natural draft, contacting the water spread across the fills.

Heat Transfer & Evaporation – As air interacts with the water, a fraction of the water evaporates. This phase change absorbs significant heat, lowering the temperature of the remaining water.

Cooled Water Collection – The cooled water collects in a basin and is pumped back into the system to repeat the cycle.

A cooling tower system is made up of several key components that work together to achieve efficient heat rejection:

This includes pumps and piping that move warm water from the process equipment to the cooling tower and return cooled water back to the equipment.

Spray nozzles, headers, and distribution troughs ensure that warm water is evenly spread over the fill media for uniform cooling.

Fill (or packing) increases the contact surface between water and air, significantly improving heat transfer efficiency.

Fans, fan motors, and air inlets/outlets manage airflow through the tower. Depending on design, airflow may be natural or mechanical.

The cooled water collects here before being pumped back to the process equipment.

Drift eliminators capture water droplets to minimize loss, and louvers help guide airflow while reducing splash-out.

Cooling tower systems vary based on airflow, configuration, and cooling mechanisms:

This classic design exposes water directly to air and utilizes evaporation for heat loss. It’s widely used in industrial, commercial, and HVAC applications.

Also known as closed-loop towers, these systems cool process fluids inside coils without direct air contact — reducing contamination and scaling.

Combining features of wet and dry cooling, hybrid towers reduce water use and can adapt to varying conditions.

Natural Draft: Uses buoyancy of warm moist air; typical in large power plants.

Mechanical Draft: Relies on fans to push or pull air through the tower; offers better control and efficiency.

The effectiveness of a cooling tower system depends on several environmental and operational factors:

Temperature and humidity (wet-bulb temperature) determine the theoretical limit of water cooling potential.

Matching water flow rates and thermal load affects how much heat a tower can reject.

Fill media condition significantly impacts heat transfer. Clogged or damaged fill reduces performance.

Well-designed fan systems and louvers influence airflow patterns and cooling efficiency.

| System Parameter | Description | Typical Value / Impact |

|---|---|---|

| Range | Temp difference between incoming and outgoing water | Larger range → better cooling |

| Approach | Difference between cooled water temp and ambient wet-bulb | Smaller approach → higher efficiency |

| Water Flow Rate | Volume of water circulated | Affects cooling capacity |

| Airflow Rate | Volume of air moved through tower | Higher airflow → greater heat rejection |

| Drift Loss | Water lost with discharge air | Lower drift → reduced water usage |

Cooling tower systems are used in nearly every industry that requires heat removal:

Large buildings and complexes rely on cooling towers to remove heat from chillers and maintain comfortable indoor climates.

Chemical plants, refineries, and manufacturing facilities use cooling towers to manage heat from machinery and processes.

Thermal and nuclear power plants use large cooling tower systems to dissipate waste heat from condensers.

Routine maintenance keeps a cooling tower system performing reliably over time:

Regular cleaning of fill media, basins, and distribution systems prevents scaling, fouling, and bacterial growth that reduce efficiency.

Fans, motors, and drives should be checked for vibration, balance, and wear to maintain stable operation.

Proper water treatment prevents mineral buildup and corrosion, which can degrade system performance.

Mach Cooling is a trusted manufacturer of cooling tower systems, offering a wide range of engineered solutions including:

Counterflow and crossflow open cooling towers

Closed loop and modular systems

Large industrial configurations with advanced materials and components

Mach Cooling systems are designed for durability, high heat rejection efficiency, and easy maintenance — making them well suited to power plants, HVAC installations, and industrial applications.

A cooling tower system is an engineered solution for removing unwanted heat through water-to-air heat transfer, often using evaporation. These systems are integral to modern industry and building management, enhancing energy efficiency and supporting continuous operation. With proper design, maintenance, and high-quality equipment — such as those supplied by Mach Cooling — cooling tower systems can deliver long-term reliable performance in demanding applications. (Mach Cooling Tower)