We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-23 Origin: Site

An in-depth guide with diagrams, tables, and applications — highlighting solutions from Mach Cooling (https://www.machcooling.com/)

Cooling towers are critical components in industrial facilities, HVAC systems, and power plants, where they remove unwanted heat from circulating water. One often-overlooked component that plays a crucial role in regulating the cooling process is the cooling tower flow control valve. This valve helps maintain proper water flow, ensures balanced distribution, enhances performance, and protects equipment from damage due to improper flow conditions.

This article explains what a cooling tower flow control valve is, how it works, why it’s important, key specifications, maintenance considerations, and how quality equipment from Mach Cooling can support optimal cooling tower performance.

A cooling tower flow control valve is a valve installed in the primary or distribution piping of a cooling tower system to regulate, balance, or limit the flow of water passing through the system. It ensures that the water flow entering various sections of the cooling tower — such as spray nozzles, distribution headers, or bypass lines — stays within design parameters, even as conditions change. (

Unlike simple isolation valves that merely open or close, flow control valves are designed to maintain a steady flow rate or respond to changing pressure conditions. This regulation is essential for cooling towers to work efficiently and avoid issues such as overflow, under-flow, or inefficient heat rejection.

Cooling towers depend on uniform distribution of hot water across fill surfaces so that maximum heat exchange can occur. If water flow is too high in one area and too low in another, the effectiveness of evaporative cooling decreases. Flow control valves help prevent such imbalances by modulating water flow based on demand and system conditions.

Proper flow control protects downstream components such as pumps, nozzles, and headers from wear due to excessive pressure or turbulence. It also helps prevent overflow or flooding of the hot water basin during sudden changes in system demand.

In systems with variable cooling loads, a flow control valve can work with actuators or building automation systems to adjust flow dynamically. This reduces unnecessary energy consumption and improves overall heat rejection efficiency, which is especially useful in large installations such as those served by Mach Cooling solutions.

A flow control valve typically uses an adjustable or automated internal mechanism (such as a valve disc, pilot, or actuator) to regulate the amount of water that passes through. Valves may work based on:

Fixed orifices that limit maximum flow

Pilot-controlled valves that adjust flow based on pressure differentials

Actuator-controlled valves that respond to control signals from sensors or systems

These mechanisms ensure that, despite fluctuations in system pressure or demand, the flow stays within desired ranges to maintain stable tower performance.

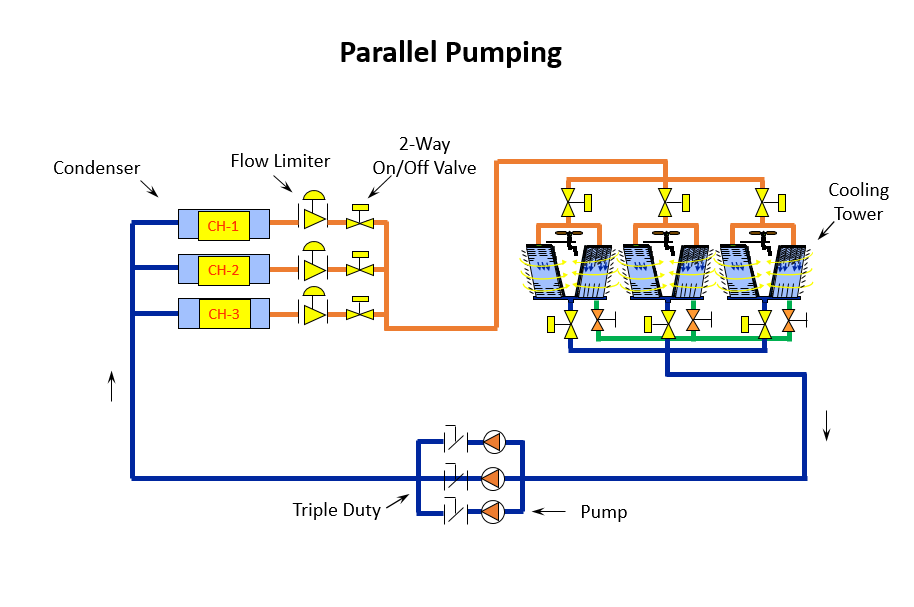

Diagrams showing how a flow control valve regulates water flow into and within a cooling tower.

When selecting a flow control valve for cooling tower applications, understanding specifications is essential. Below is a summary of typical criteria:

| Specification | Description |

|---|---|

| Flow Capacity (m³/h or GPM) | Maximum water that can pass through the valve |

| Pressure Rating | Maximum system pressure the valve can safely handle |

| Valve Type | Globe, butterfly, or pilot-controlled designs suitable for cooling tower use |

| Material | Stainless steel, corrosion-resistant alloys or engineered plastics |

| Actuation | Manual, pneumatic, electric or automatic control |

| Shut-off Rating | Ability to fully stop flow when needed |

Quality valves in cooling tower applications often feature corrosion-resistant bodies and positive shut-off capabilities to withstand the wet, chemical-exposed environment typical of towers.

Simple valves adjusted by an operator to set or limit flow to a desired level. These are common in smaller systems or where automation is not required.

Often actuator-controlled and connected to building management systems (BMS), these valves can adjust flow in real time based on temperature, pressure, or flow sensors. This type can greatly improve the efficiency and response of a cooling tower system.

These devices maintain a constant flow regardless of downstream pressure fluctuations. They are particularly useful in systems where stable flow is necessary despite changing loads or pump speeds.

Cooling towers use a variety of valve types, each serving a different purpose:

| Valve Category | Primary Function |

|---|---|

| Flow Control Valve | Regulates flow to maintain optimal conditions |

| Isolation Valve | Completely stops flow for service or safety |

| Distribution Valve | Balances flow between sections or cells |

| Float Valve | Controls makeup water level in basins |

Flow control valves are distinct in that they manage active flow rates dynamically, whereas isolation valves simply start or stop flow and distribution valves split flow between branches.

Flow control valves can be installed:

At the inlet of cooling tower distribution systems

In bypass lines to protect against overflow

In branches to individual cells or nozzles

Correct placement ensures water is delivered at the intended rate and pressure to each cooling section.

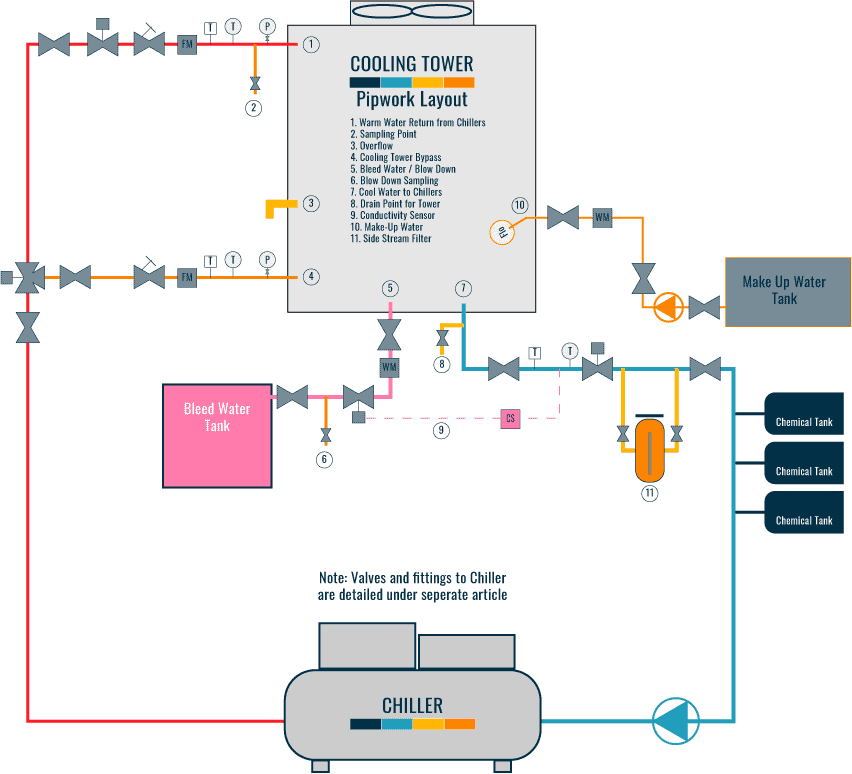

Example piping schematic showing a flow control valve regulating water distribution within a cooling tower system.

By matching water flow to system demand and maintaining stability during partial load conditions, flow control valves ensure consistent cooling tower performance.

Properly balanced flow can reduce pump energy consumption and avoid unnecessary overcooling or inefficient operation.

Controlling flow avoids excessive velocities and pressure fluctuations, which can prolong the life of pumps, pipes, and distribution components.

Although designed for reliability, flow control valves require periodic checks to:

Confirm proper movement and response

Detect leakage around seals

Ensure no blockage from debris

Validate actuator or control signal performance

| Task | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Monthly | Detect visible wear, corrosion |

| Functional Test | Quarterly | Ensure the valve responds correctly |

| Seal Inspection | Twice/year | Prevent leaks |

| Control System Check | Annually | Confirm actuator/calibration work |

Regular maintenance prevents performance degradation and extends valve life.

Mach Cooling (https://www.machcooling.com/) designs and integrates high-quality cooling tower systems, including intelligent piping and valve support that accommodate modern flow control technologies.

Their engineering teams ensure that flow control valves are properly selected, sized, and positioned to support optimal heat rejection, balanced distribution, and efficient operation across variable loads.

Whether for new installations or upgrades to existing towers, Mach Cooling’s approach ensures that flow control components work harmoniously with other system parts, improving reliability and operational performance.

A cooling tower flow control valve is a key component that regulates the flow of water through a cooling tower system, helping maintain balanced distribution, protect equipment, and optimize energy usage. Whether manual or automatic, these valves improve cooling tower performance and stability, especially in complex or variable-load environments.

With quality solutions from Mach Cooling (https://www.machcooling.com/), engineers and facility managers can ensure that their cooling towers are equipped with reliable, efficient flow control components that support long-term performance and cost-effective operation.