We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

A cooling tower fan is one of the most essential components in any water cooling tower. Its main purpose is to move large volumes of air through the tower so that heat can be effectively removed from circulating water. Without a properly functioning fan, the entire water cooling tower system—whether it is a water cooled tower, closed loop cooling tower, blowdown water cooling tower, chilled water cooling tower, or condenser water cooling tower—will suffer from reduced cooling capacity, higher energy consumption, and increased operating costs.

Below, we explain what a cooling tower fan is, how it works, the different types, and why proper fan selection is vital for performance. Content references the expertise of Mach Cooling: https://www.machcooling.com/.

A cooling tower fan is a mechanical device designed to push or pull air through the cooling tower structure. By driving airflow across the fill media where hot water is distributed, the fan accelerates:

Evaporative cooling

Heat transfer

Air–water contact efficiency

In a water cooling tower system, the fan ensures continuous cooling even when natural wind or ambient conditions are insufficient. This is especially important in HVAC, industrial processes, and power plants.

Warm water enters the cooling tower and is sprayed over the fill.

The cooling tower fan either pulls air upward (induced draft) or pushes air in from the sides/bottom (forced draft).

As air moves across the falling water, heat is removed through evaporation.

Cooled water collects in the basin and is pumped back to the process or chiller.

This airflow created by the fan is essential for condenser water cooling tower and chilled water cooling tower applications where stable water temperature is required.

Cooling tower fans are usually powered in one of three ways:

Direct drive: Motor directly connects to the fan (low maintenance).

Belt drive: Flexible, cost-effective, easy to adjust speed.

Gear drive: Strong torque for large industrial towers.

Each method affects reliability, noise, and power consumption.

Located at the top of the tower

Pull air through the fill and discharge it upward

Highly efficient with minimal hot-air recirculation

Most commonly used in water cooled tower and condenser water cooling tower systems

Installed at the bottom or sides

Push air into the cooling tower

Easier maintenance access

May require more power and can cause recirculation if not designed well

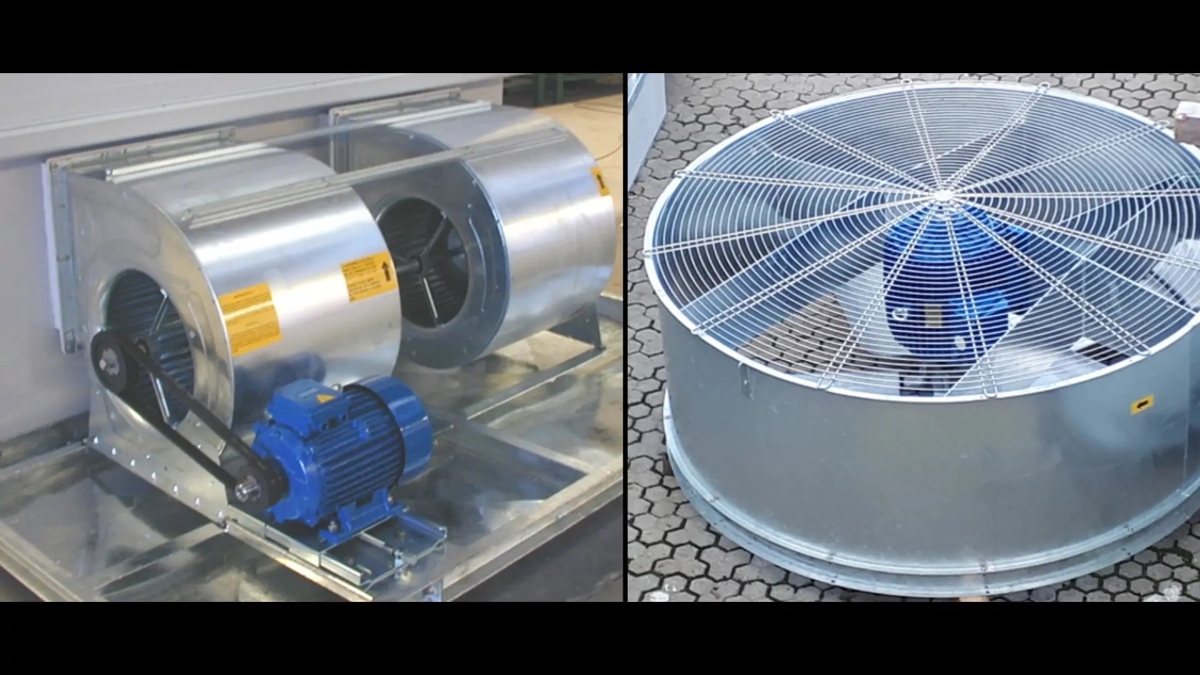

| Fan Type | Airflow | Pressure | Applications |

|---|---|---|---|

| Axial Fan | Very high | Low | Most water cooling towers, best efficiency |

| Centrifugal Fan | Moderate | Higher | Indoor/closed towers or noise-sensitive areas |

Axial fans dominate the cooling tower market, including those supplied by Mach Cooling.

In these open-loop structures, the fan drives massive airflow to support evaporation. A poorly performing fan directly reduces cooling efficiency.

Since process fluid does not contact air, airflow passes over coils. Strong fan performance ensures proper heat exchange across coil surfaces.

Fan airflow influences evaporation rate, which impacts cycle of concentration and blowdown frequency. Better airflow = more efficient water management.

Stable return-water temperature is essential for chillers. Variable-speed fans are often used to maintain precise temperature control and reduce electricity use.

| Parameter | Importance |

|---|---|

| Fan diameter | Larger diameter = higher airflow with lower RPM |

| Blade material | FRP, aluminum, or stainless steel for durability |

| Noise level | Important in residential or commercial areas |

| Energy efficiency | Affects long-term operating cost |

| Variable-speed compatibility | Ideal for HVAC towers |

| Corrosion resistance | Critical due to wet operation environment |

A properly selected fan can improve tower cooling capacity by 10–25% while reducing energy consumption.

Inspect blades regularly for cracks and dirt buildup

Check motor alignment and vibration

Lubricate bearings and gearbox (if applicable)

Verify belt tension in belt-driven systems

Clean air inlet louvers to avoid airflow blockage

Monitor fan motor amps for overload

Well-maintained fans reduce energy cost and extend tower life.

Mach Cooling (https://www.machcooling.com/) specializes in:

Precision-engineered cooling tower fans

Complete water cooling tower systems

Energy-efficient designs for chilled water and condenser water towers

High-performance solutions for closed loop and water cooled tower applications

Their fans feature low noise, high durability, and optimized aerodynamic design.

A cooling tower fan is more than just a rotating component—it is the core driver of efficient heat rejection in any water cooling tower system. Whether used in industrial cooling, HVAC chilled water loops, or high-performance condenser water towers, the fan ensures stable airflow, strong evaporation, and reliable cooling.

Selecting the right fan, ensuring proper maintenance, and relying on trusted manufacturers like Mach Cooling will significantly improve cooling tower performance, energy efficiency, and long-term system reliability.