We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-23 Origin: Site

In cooling tower systems, especially in industrial, commercial, and power plant applications, achieving uniform distribution of hot water is crucial for efficient heat transfer and optimal performance. One key component that enables this is the cooling tower distribution valve — a specialized valve designed to regulate and control how water enters the distribution system of a cooling tower.

This article explains what a distribution valve is, how it works, why it’s important, its specifications, and how top-quality components from Mach Cooling can improve cooling tower performance.

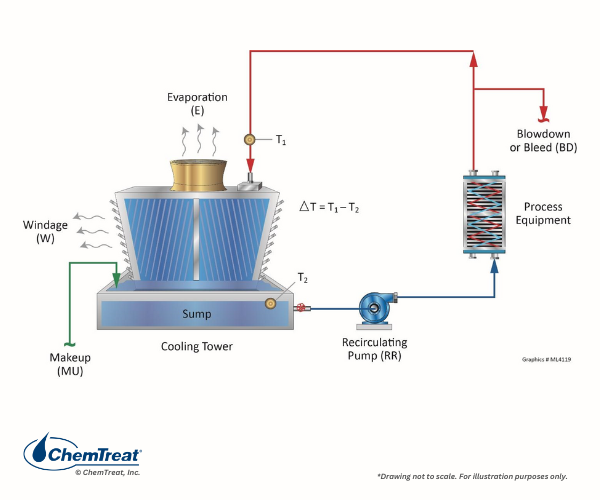

A cooling tower distribution valve is a control device installed in the water distribution system of a cooling tower. Its primary purpose is to regulate the flow of hot water coming from the condenser or heat source into the distribution system evenly across cells or spray areas.

By doing this, the valve ensures that water is evenly distributed to the fill media where heat exchange with air takes place — maximizing the cooling effectiveness of the tower and helping maintain stable operation across all areas of the system.

In cooling tower cells, water must be spread uniformly so that every part of the fill media receives sufficient contact with air. Uneven water distribution can lead to:

Reduced heat transfer efficiency

Uneven cooling across cells

Higher operating costs due to inefficient heat rejection

Distribution valves help manage and balance flow so that each segment of a cooling tower gets the right amount of water, improving overall thermal performance.

Advanced distribution valves, such as those used by Mach Cooling, can improve performance by:

Balancing flow rates into multiple cells

Preventing overflow or under-flow conditions in specific areas

Reducing pressure drop within the system

Supporting smoother operation with less strain on pumps and nozzles

A cooling tower distribution valve typically operates by adjusting internal passages to control how much hot water flows into different distribution headers or cells. A properly designed valve must:

Be corrosion resistant

Withstand variable water flow pressures

Allow accurate flow control without leaking

Operate reliably with low maintenance

Technology such as positive shut-off seals and internal guide systems helps ensure consistent performance.

Regulate Water Flow: Controls volume of hot water entering each cooling cell.

Balance Distribution: Ensures balance between multiple cells or nozzles, especially in multi-cell towers.

Reduce Leakage: Modern valve designs provide positive shut-off to prevent unwanted leakage or water waste.

Resist Corrosion: Materials like stainless steel and engineered plastics withstand harsh water environments.

Understanding valve specifications helps engineers and operators choose the right component for a given project. Common specification criteria include:

| Specification | Description |

|---|---|

| Flow Capacity (m³/h / GPM) | Maximum water volume the valve can handle |

| Material of Construction | Stainless steel, UHMW-PE plastic, corrosion-resistant components |

| Valve Type | Globe valve, ball valve, or custom distribution valve |

| Pressure Rating | Maximum safe operating pressure |

| Sealing / Shut-off Rating | Effectiveness of controlling leakage |

| Maintenance Requirements | Service interval and ease of serviceability |

Mach Cooling works with partners and designs cooling towers to accept high-quality distribution valves that meet rigorous industry standards, ensuring long-term reliability and performance.

Several types of valves are used in cooling tower systems:

Simple valves that require an operator to adjust water flow manually. These are less precise but cost-effective for smaller systems.

Designed to balance water supply across multiple distribution headers or cells automatically or with minimal adjustment, improving uniformity and stability.

Use actuators or sensors to dynamically regulate water flow based on system demand and pressure conditions — ideal for large installations with variable loads.

A distribution valve is typically installed in the water distribution network that feeds hot water into a cooling tower’s spray nozzles or troughs.

In a crossflow cooling tower, the distribution valve feeds water into a distribution box, which then directs water to nozzles. In counterflow systems, valves may feed directly into headers that lead to spray nozzles or distribution troughs.

Proper integration ensures that water flow is balanced, reducing the risk of dry spots or flooded zones that can reduce heat transfer efficiency.

Performance of distribution valves directly impacts cooling tower effectiveness:

When valves are correctly sized and calibrated, water is evenly distributed across fill media — leading to more effective heat exchange and lower outlet water temperatures.

High-quality distribution valves reduce turbulence and unnecessary water flow variations, minimizing strain on pumps, piping, and downstream components.

Regular inspection and maintenance of distribution valves are essential. Even though modern designs reduce maintenance needs, failing to check valves can lead to:

Blockages

Corrosion

Improper flow distribution

Reduced cooling effectiveness

| Task | Frequency | Purpose |

|---|---|---|

| Visual Inspection | Monthly | Identify leaks or corrosion |

| Flow Testing | Quarterly | Verify correct distribution |

| Seal Check | Biannually | Ensure proper shut-off |

| Clean Foreign Material | As needed | Prevent clogging |

Top manufacturers such as Mach Cooling design systems that allow easy access to distribution valves for maintenance and replacement.

A cooling tower includes various components that manage water distribution. While nozzles directly spray water and headers carry water to distribution points, the distribution valve is critical for controlling how much water flows into those systems.

| Component | Primary Purpose |

|---|---|

| Distribution Valve | Controls and regulates water flow |

| Distribution Header | Carries water to the distribution network |

| Nozzles/Spray Devices | Spray water over fill media |

Mach Cooling (https://www.machcooling.com/) integrates high-quality distribution valves into its cooling tower designs to ensure optimal thermal performance. These valves:

Are resistant to corrosion and harsh water conditions

Provide stable flow control

Are easy to maintain and replace

Help balance flow across multiple towers or cells

Mach Cooling’s engineering ensures that valve selection, placement, and accessibility align with system design requirements — maximizing cooling efficiency and long-term reliability.

A cooling tower distribution valve is a vital component in any cooling water system, controlling how hot water is delivered into the distribution network and ensuring even, balanced flow across all cooling surfaces. Proper selection, installation, and maintenance of these valves enhance cooling performance, reduce energy costs, and prolong equipment life.

Manufacturers like Mach Cooling (https://www.machcooling.com/) offer tailored solutions that incorporate durable, high-performance valves — ensuring reliable operation and efficient heat rejection in industrial or commercial cooling systems.

Whether for new construction or upgrading existing towers, understanding the role and importance of distribution valves is key to maximizing cooling tower performance.