We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-23 Origin: Site

Cooling towers are essential for removing unwanted heat in industrial processes, HVAC systems, and power stations. Within a cooling tower, a cooling tower cell represents a modular cooling unit that contributes to the overall heat rejection performance of the system. In modern engineering applications, understanding what a cooling tower cell is — and how it functions — is key to designing and operating efficient thermal systems.

This article explores Cooling Tower Cell Design, functions, performance, comparisons, specifications, maintenance, and capacity — all with references to advanced solutions from Mach Cooling (https://www.machcooling.com/).

A cooling tower cell is an individual operating section or module of a multi-cell cooling tower. In large systems, especially those used in industrial plants and power stations, multiple cells operate in parallel to achieve greater cooling capacity and operational flexibility.

Mach Cooling offers a wide range of Modular Cooling Tower Cells that can be matched to process requirements, allowing systems to grow with demand while maintaining high efficiency and reliability.

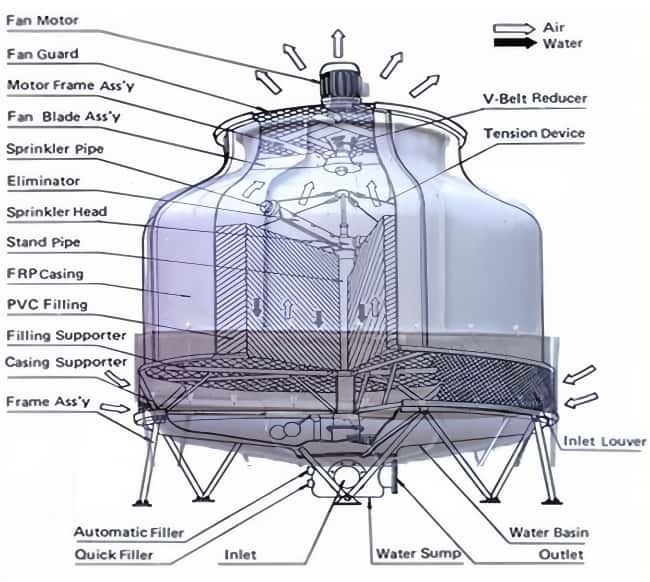

Cooling Tower Cell Design refers to the engineering and layout of the individual unit within a larger cooling tower assembly. Good design ensures:

Optimized heat transfer

Uniform water distribution

Controlled airflow patterns

Structural strength

All of which contribute to cooling efficiency, durability, and lower operating costs.

Fill Materials: Increase the surface area for water–air interaction.

Water Distribution System: Ensures even water spread.

Air Inlet Louvers: Direct airflow efficiently into the cell.

Fans: Provide controlled airflow (in Cooling Tower Fan Cell designs).

Each component must be designed together to improve thermal performance and minimize resistance to airflow.

Modular Cooling Tower Cells are self-contained cooling units that can be combined to build a larger system. Instead of constructing a single very large tower, engineers can configure multiple cells side-by-side.

Benefits of modularity include:

Easy scaling of capacity

Redundancy in operation

Maintenance flexibility (one cell can be serviced without shutting down the system)

Simplified logistics and installation

Multi-cell towers are named based on the number of cells, such as 2-cell, 3-cell, or more. Cells are usually identical, which simplifies manufacturing and maintenance.

| Cell Count | Typical Application | Benefit |

|---|---|---|

| 1 | Small HVAC systems | Cost effective |

| 2–3 | Commercial facilities | Redundancy + capacity |

| 4+ | Industrial and power plants | High capacity + flexible operation |

Mach Cooling provides a range of multi-cell cooling tower solutions with customizable layouts to meet process cooling demands.

Cell performance is measured by how effectively it reduces water temperature per unit of heat load. Key factors include:

Fill Efficiency

Airflow rate

Water flow distribution

Fan performance

Ambient wet-bulb temperature

Performance testing often involves measuring approach temperature — the difference between cooled water temperature and ambient wet-bulb temperature. Smaller approaches indicate higher efficiency.

| Parameter | Before Optimization | After Optimization (Mach Cooling) |

|---|---|---|

| Approach (°C) | 7 | 4 |

| Water Flow (m³/h) | 120 | 120 |

| Heat Rejection (kW) | 450 | 500 |

| Fan Power (kW) | 18 | 15 |

Mach Cooling cells are designed to maintain stable performance even under varying loads, reducing energy consumption and maximizing heat rejection.

A Cooling Tower Fan Cell specifically describes a cell that includes an integrated fan unit — typically seen in mechanical draft towers. Fans drive air through the cell, enabling heat transfer by forcing or inducing airflow.

Two common fan types:

Induced Draft Fans: Pull air through the cell (most common)

Forced Draft Fans: Push air into the cell

The right fan selection is vital to achieving the desired cooling capacity while minimizing energy consumption.

Cell capacity refers to the amount of heat that a single cooling tower cell can reject, usually expressed in kW or refrigeration tons (RT). Capacity is influenced by:

Airflow

Water flow rate

Fill area

Fan power

Ambient conditions

For multi-cell towers, total capacity is the sum of individual cell capacities. Configuring cells in stages can help match plant loads precisely.

A cooling tower represents the entire equipment, whereas a cooling tower cell is a building block of the tower in modular or multi-cell systems.

| Characteristic | Cooling Tower Cell | Cooling Tower |

|---|---|---|

| Definition | Single cooling unit | Complete assembly |

| Function | One module of operation | Total cooling capacity |

| Flexibility | High | Depends on cell count |

| Maintainability | Easy | Depends on size |

In systems using Mach Cooling technology, understanding this difference helps users choose the right number and configuration of cells for their thermal load.

Specs define how a cell will perform under set design conditions. Common specification items include:

Maximum water flow (m³/h)

Design wet-bulb temperature

Approach temperature

Airflow rate (m³/min)

Motor power & type

Material of construction (e.g., FRP)

Detailed specifications support proper system design, allowing engineers to match a cooling tower cell to cooling requirements.

Mach Cooling publishes comprehensive Cooling Tower Cell Specifications for each model, enabling accurate selection and system integration.

Routine maintenance ensures that cooling tower cells continue to operate at peak efficiency and helps prevent:

Scaling and fouling

Biofilm buildup

Fan imbalance

Corrosion issues

| Task | Purpose |

|---|---|

| Clean fill media | Improves heat exchange |

| Check fans & belts | Reduces vibration & power waste |

| Inspect drift eliminators | Avoids water loss |

| Monitor water quality | Prevents corrosion |

Mach Cooling offers maintenance guides and service support that help plant operators keep cooling tower cell systems running reliably for decades.

Cooling tower cells are widely used in:

Power stations

Petrochemical plants

HVAC systems for large buildings

Industrial manufacturing

Data centers requiring precise thermal control

Mach Cooling solutions are engineered for diverse environments — from heavy industrial to commercial HVAC — with a focus on performance, durability, and ease of maintenance.

A cooling tower cell is more than a component — it is a modular cooling unit that enables scalable, efficient heat rejection in modern cooling tower systems. Understanding Cooling Tower Cell Design, Modular Cooling Tower Cells, Cooling Tower Cell Performance, Cooling Tower Fan Cell, Cooling Tower Cell Maintenance, Cooling Tower Cell Capacity, and how a cell differs from a full tower empowers engineers and operators to choose the right solution for their needs.

With industry-leading products and engineering support, Mach Cooling (https://www.machcooling.com/) delivers advanced cooling tower cells that combine performance, durability, and operational ease — meeting the demands of today’s complex thermal systems.