We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-11 Origin: Site

A closed loop cooling tower — also called a water cooled tower or closed loop cooling tower system — is a specialized type of water cooling tower designed to cool down process fluids (e.g., water, glycol, oil) without exposing them directly to outside air. Inside this tower is a carefully arranged system of components: sealed coils, spray water distribution, air flow, and drift-elimination. The internal structure ensures efficient heat rejection while protecting the process fluid from contamination. In this article, we explore what the interior of such a tower looks like, how each component functions, and how the system operates as a whole — with reference to MACH Cooling’s design.

In an open cooling tower, the water to be cooled is sprayed directly into the tower and comes into direct contact with air. As a result, the water is exposed to ambient air, which can introduce contaminants, scale, or biological growth.

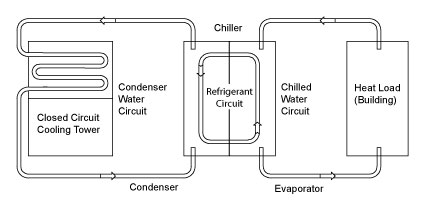

By contrast, in a closed loop cooling tower system, the fluid being cooled (process fluid) circulates inside a sealed coil (or heat exchanger) and never contacts external air.

The tower also contains a second loop — the “spray water + air” loop — which evaporatively cools the coil, thus indirectly cooling the fluid inside.

This separation ensures the process fluid remains clean, free from airborne dirt, debris, and other contaminants — a major advantage for industrial, HVAC, or process-water applications that demand fluid purity.

Because of this architecture, if you peered inside such a closed-loop (water cooled) tower, you would not see the hot process fluid directly spraying or dripping — instead you’d see coils, spray nozzles, fill media, air louvers, fans, a water basin, and other structural components arranged for indirect cooling.

Below is a schematic-like description of what you'll find inside a typical closed loop cooling tower (such as those built by MACH Cooling), along with images and a summary table.

The heart of the system — a sealed coil (made of copper, stainless steel, or galvanized steel) through which the process fluid (the fluid you want to cool) circulates.

Because the coil is sealed, the fluid is not exposed to outside air — preserving cleanliness and preventing contamination or fouling.

The coil can be arranged in a serpentine or multi-pass layout to maximize surface area and heat exchange efficiency.

Surrounding the coil, a spray water loop sprays water over the outer surface of the coils. This spray water — not the process fluid — is what interacts with ambient air.

The spray helps to form a thin water film or fine droplets, increasing surface area and im

proving heat transfer by evaporation/convection.

Materials for spray headers and nozzles can be PVC, brass, stainless steel depending on design and environment.

To remove heat, ambient air is drawn or forced across the coil and spray-water film. Fans (axial or centrifugal) create airflow, either as induced draft (pulling air up through the tower) or forced draft.

Air inlets or louvers at the bottom or sides allow fresh air into the tower housing.

As air moves over the wetted coil/spray, evaporation and convection remove heat; the warm, moist air then is exhausted out of the tower.

A drift eliminator is installed above the coil/spray zone to catch water droplets carried upward by the airflow, preventing excessive water loss and minimizing “drift.”

Depending on design, the tower may also incorporate fill media or structured packing to encourage uniform distribution of spray water over the coils and maximize contact area for evaporation/heat transfer.

At the bottom of the tower there is a basin ( sump ) that collects the spray water after it has cascaded down from the coils.

A pump draws water from this basin back to the spray distribution system, maintaining continuo

us circulation of the spray water loop.

Only minimal make-up water is needed to replace what evaporates out, meaning lower water consumption than open systems, and less maintenance on the process fluid side.

The exterior shell or housing of the water cooled tower provides structural support, airflow channels, and protection from environment. Materials vary (FRP, galvanized steel, stainless steel, depending on design).

Louvers or air inlet panels at lower levels. Access doors/panels for maintenance may be included.

| Component / Area | Function / Role |

|---|---|

| Heat-exchanger coil (closed circuit) | Contains process fluid; allows indirect heat exchange without exposure to air |

| Spray water nozzles & distribution system | Spray water over coil to enable evaporative cooling and convective heat transfer |

| Fans / Air inlets / Louvers | Drive air flow over wetted coils and spray water to exhaust heat and moisture |

| Drift eliminators | Capture entrained water droplets in exhaust air to prevent water loss / drift |

| Cold-water basin & recirculation pump | Collect spray water and recirculate it for continuous cooling loop |

| Tower shell / structural casing | Enclose the system, support components, channel airflow, and provide maintenance access |

The hot process fluid — which needs cooling — enters the sealed coil inside the tower. Because the coil is closed, the fluid remains uncontaminated and isolated from outside air or spray water.

Simultaneously, the spray pump pushes water from the basin up to the spray nozzles. This water is distributed over the coil’s outer surface.

Fans draw or force ambient air across the wetted coil/spray, enabling evaporative cooling and convective heat transfer. The coil wall conducts heat from the process fluid to the spray water and air.

As air flows over the wet coil/spray water surface, a portion of the spray water evaporates, absorbing latent heat. This removes heat from the coil, cooling the fluid inside.

The warm, moisture-laden air is expelled out of the tower. Meanwhile, the remaining spray water — now cooled — drips down into the basin.

The cooled process fluid exits the bottom of the coil and returns to the system (chiller, process equipment, HVAC loop, etc.) for reuse.

The spray water collected in the basin is pumped back up, making the spray-loop continuous. Only small amounts of make-up water are added to compensate for evaporation losses.

This two-loop, indirect cooling method ensures high thermal performance while protecting fluid cleanliness and minimizing maintenance needs.

Using a closed loop cooling tower system (i.e. a water cooled tower / closed loop cooling tower) brings several benefits — especially for industrial, HVAC, or sensitive process applications. MACH Cooling’s product line emphasizes these advantages. According to MACH:

Clean Process Fluid: Because the process fluid is sealed inside the coil, it's never exposed to outside air, dust, scale, or biological contaminants. This maintains fluid purity and reduces fouling.

Simplified Maintenance: Only the spray-water loop requires periodic maintenance and treatment. The main process loop remains clean and tends to require less frequent cleaning.

Year-Round Operation & Flexibility: Such towers can operate in a variety of settings — HVAC systems, data centers, industrial process cooling (food, pharma, manufacturing), chillers, etc.

Efficient Heat Rejection with Lower Water Use: Because only spray water evaporates (not the process fluid), water usage is often more efficient than open-loop towers in sensitive applications.

From the inside, a MACH closed loop cooling tower is not just a big water-spray tower — it’s a carefully engineered heat-exchange and fluid-management system that balances thermal efficiency, fluid cleanliness, water conservation, and operational reliability.

Suppose you have a water cooled tower supplied by MACH Cooling. Inside you would find:

A robust sealed coil bundle (copper, stainless, or galvanized) through which your process fluid circulates;

A stainless-steel or FRP casing housing the coil and all internal components;

A network of PVC (or stainless) spray nozzles and distribution headers above the coil;

Air inlets or louvers at lower sections; axial or centrifugal fans on the top for airflow;

Drift eliminators installed near the air outlet to catch water droplets;

A basin at the bottom to collect spray water, along with a recirculation pump and make-up water valve;

Control and instrumentation (valves, sensors) to regulate spray flow, fan speed, water level — ensuring effective, stable cooling.

If you opened a maintenance hatch, you’d see the coil bundle and spray-water arrangement first; typically you wouldn’t see the process fluid, because it remains enclosed.

While closed loop cooling towers have many advantages, understanding their internal structure is important for proper maintenance and operation:

Spray Water Quality Matters: Since spray water contacts the coils and air, it can accumulate impurities — requiring periodic treatment (anti-scaling, anti-microbial) especially in hard-water areas.

Drift & Water Loss Management: Even with drift eliminators, some evaporation and drift loss occurs, requiring make-up water and possibly bleed-off to prevent mineral buildup.

Coil Inspection & Corrosion Prevention: Over time, coils may corrode or scale (depending on spray-water quality), so periodic inspection is needed.

Fan and Pump Maintenance: Fans and pumps are essential to airflow and spray circulation — their failure can drastically reduce cooling performance.

System Design Must Suit Application: Choosing coil material (copper vs stainless vs galvanized), spray-loop materials, and tower housing must match environmental, water-quality, and process requirements.

The inside of a closed loop cooling tower (or water cooled tower / closed loop cooling tower system) — such as those supplied by MACH Cooling — is a carefully engineered assembly of sealed coils, spray-water distribution, air flow, drift control, and recirculation mechanisms. Unlike open cooling towers, the process fluid remains sealed, ensuring purity and preventing contamination, while a secondary water-and-air loop handles heat rejection effectively.

Internally, you’ll find a coil bundle, spray nozzles, fans, drift eliminators, a water basin and pump, and structural casing — all working together to deliver efficient, stable cooling. This design is ideal for industrial process cooling, HVAC, data centers, and other applications requiring clean, reliable water cooling.