We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-10 Origin: Site

A cooling tower is an essential component of many industrial and HVAC (heating, ventilation, air-conditioning) setups. In its simplest form, a water cooling tower (also called a water cooled tower or water cooling tower system) works by circulating warm water through a structure where the water is sprayed over “fill” material so that air can pass over it — evaporation removes heat, cooling the water before it returns to the system. (CHT TECK CO., LTD)

While cooling towers are designed to operate stably, there are circumstances under which they overflow — leading to wasted water, potential structural damage, maintenance headaches, and inefficiencies. Below is an analysis of what causes a cooling tower to overflow, how those causes tie into typical problems found in cooling tower operation, and what can be done to avoid these issues.

(Note: This discussion applies generally to water cooling towers; a manufacturer like machcooling.com must take these into account for design, installation, and maintenance of their water cooling tower systems.)

Before diving into overflow causes, it helps to understand how a typical water cooling tower system is supposed to work.

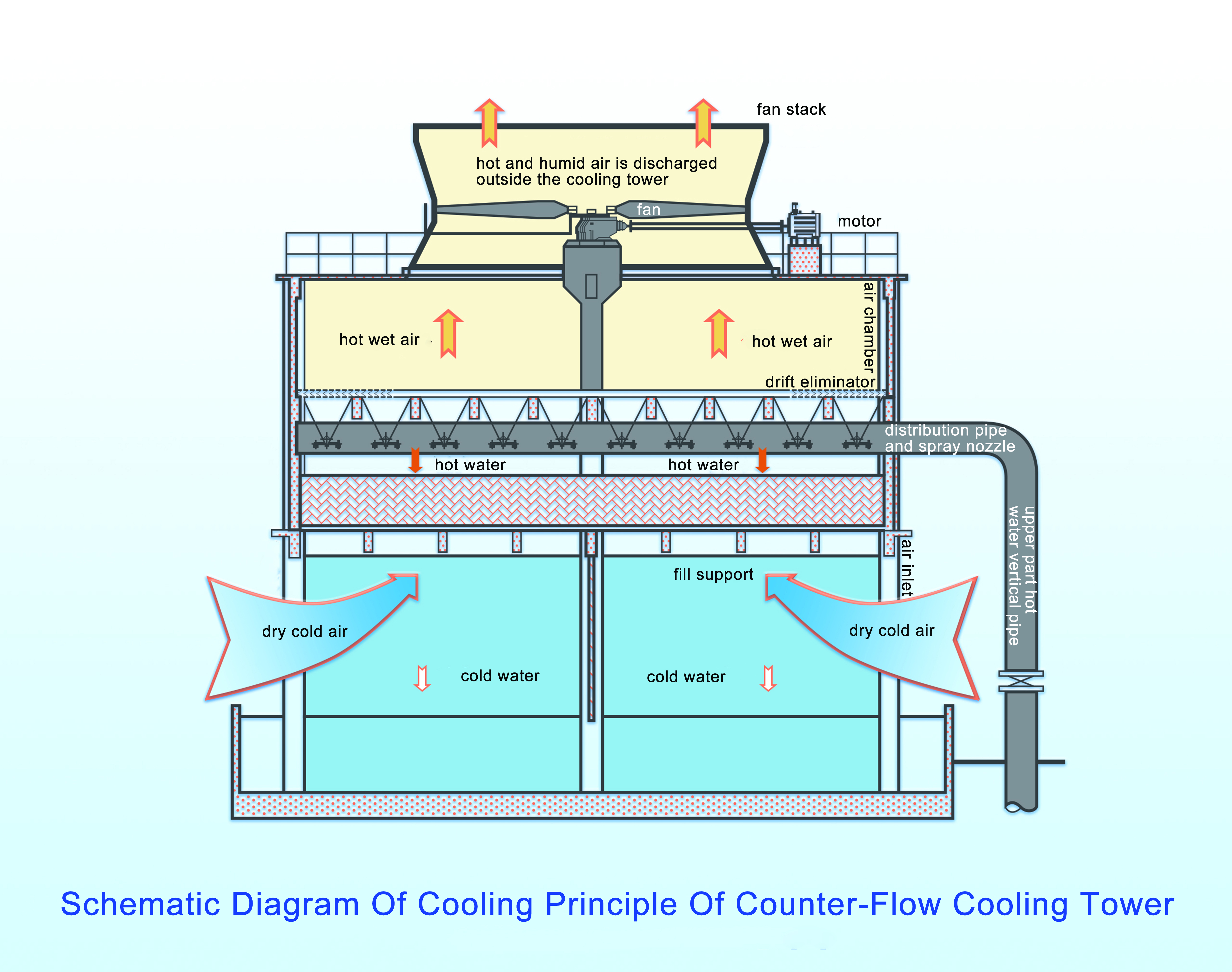

Warm water from a building’s condenser or industrial process is pumped to the top of the tower and sprayed out via nozzles.

The sprayed water flows down over “fill” (or packing) — a structured medium that increases surface area for the water — enhancing contact between water and air.

Meanwhile, air — drawn by a fan (in mechanical-draft towers) or moving naturally (in natural-draft towers) — flows upward, contacting the falling water. The air picks up heat and water evaporates. Evaporation removes heat from the remaining water, cooling it.

The cooled water collects at the bottom basin (sump), from where it is recirculated back into the system. Meanwhile, water lost to evaporation (and a small amount lost to “drift” — water droplets carried out with the airflow) is compensated by adding “make-up water.”

Periodically, some water is discharged (“blowdown”) to control total dissolved solids (TDS) and prevent scaling or corrosion.

A properly designed and maintained cooling tower will have a basin brim or overflow drain to prevent overfilling. If basin water level rises beyond the brim due to unusual conditions, excess water should go to drain.

Nonetheless, under certain conditions — mis-design, mis-operation, or malfunction — the tower can overflow inadvertently.

Here are the most frequent causes that lead a water cooled tower to overflow. Many of these are interlinked — a problem in one area (e.g., water flow distribution) can cascade into overflow.

Multiple towers connected: uneven flow or imbalance — When more than one cooling tower is connected in a system (common in large facilities), differences in tower sizes, sump elevations, or resistances in the piping can lead to uneven water distribution. If one tower receives more water in than it can send out (or circulate), its sump may overfill and overflow.

Inlet/outlet valve arrangement problems — Some designs use electric valves at the inlets but not at the outlets. Under low-load conditions or single-tower operation, water can accumulate in the sump because water exiting is limited, causing overflow.

Gravity drainage from elevated condenser or piping — If associated condenser or piping is at a higher elevation than the cooling tower sump, when pumps shut off, water can drain by gravity into the tower, flooding the sump beyond capacity.

These design or piping balance issues are among the most frequent structural or hydraulic causes of overflow — not due to water loss from evaporation or drift, but rather improper system layout or operation.

A malfunctioning makeup-water valve (or a makeup-water control system failure) — for example, a valve stuck open — can continuously supply fresh water even when the system does not actually need it. That excess makeup water will accumulate in the basin, leading to overflow. This often happens when the float valve or sensor controlling basin level fails.

In some cases, falling water can produce foam (for example due to chemical imbalance, high organic load, excessive microbial growth), which reduces effective evaporation and causes abnormal water behavior.

If operators see water loss (drift, leaks, blowdown) and compensate by adding too much makeup water — perhaps reacting to perceived water shortage — they may inadvertently overfill the basin.

When spray nozzles or distribution systems inside the cooling tower get clogged — by scale, sediment, algae, biofilm, or other debris — water does not distribute properly over the fill. This can lead to pooling, uneven flow paths, and ultimately too much water collecting in the sump rather than being evaporated evenly.

Similarly, fouling or scaling in fill media reduces heat transfer efficiency, leading to less evaporation than expected. With the same makeup water rate, the basin may collect excess water over time, leading to overflow.

Over time, components of the cooling tower (basin, trays, gaskets, seals) can corrode or degrade — especially if water chemistry is not properly controlled.

Corroded basins or damaged collection trays — can leak or crack, causing water to bypass normal drainage or float systems, leading to overflow or uncontrolled water loss.

Faulty float valves or overflow alarms — if the float valve controlling makeup water fails, or if overflow alarms are missing or not functioning, operators may not realize the basin is overfilling until overflow occurs.

Let’s consider a typical scenario in a facility using a water cooling tower system from a manufacturer such as machcooling.com.

| Condition / Event | What Happens / Why Overflow May Occur |

|---|---|

| Two or more cooling towers connected — one running, one idle (low load) | The running tower receives circulating water; the idle one may still receive makeup water via shared supply — idle sump overfills & overflows. |

| Makeup valve stuck open | Makeup water continuously enters sump even without evaporation losses — water level rises to brim → overflow. |

| Spray nozzles / fill clogged with scale or algae | Water distribution fails; less evaporation; water accumulates in basin → eventually overflow. |

| Corrosion / structural damage in basin or gaskets | Basin integrity compromised, float valve fails or leak path created → basin doesn’t drain properly; overflow or uncontrolled leakage. |

| High water loss from drift / blowdown, aggressive makeup compensation | Operators overcorrect water loss by excessive makeup water → basin fills beyond capacity. |

Overflow in a water cooling tower system is not simply a nuisance — it has real operational, economic, and environmental consequences:

Wasted water — Overflow means water is lost unnecessarily; when makeup water is used to compensate, water consumption rises.

Chemical and treatment loss — Cooling towers often rely on water treatment chemicals (for scale, corrosion, microbial control). Overflow dilutes or flushes out these chemicals, leading to poor water quality and increased maintenance costs.

Structural or equipment damage — Repeated overflows may damage components around the tower (pumps, basins, building surfaces), cause corrosion, or speed up wear and tear.

Reduced efficiency and higher operating cost — Overflow often indicates underlying issues (imbalance, clogging, fouling) that reduce heat transfer efficiency, forcing the system to work harder, consume more energy, or run less effectively.

Environmental / regulatory issues — In areas with water scarcity or strict discharge regulations, overflow can violate rules or lead to wastewater fines. Wasteful blowdown and makeup use also increases environmental footprint.

To reduce the risk of overflow and maintain efficient operation, cooling tower operators — and manufacturers such as machcooling.com — should follow these best practices:

When multiple towers are used together, design piping carefully — ensure balanced flow, consider equalization lines between sumps to avoid uneven water levels.

Include overflow drains and float valves — and make sure they are correctly located and functional. Overflow alarms or sensors should be standard.

Elevation planning — avoid placing condensers or supply piping higher than the cooling tower basin in a way that allows unintended gravity drainage when pumps stop.

Clean and inspect spray nozzles, distribution trays, fill media. Remove scale, sediment, algae, biofilms to ensure proper water distribution and evaporation.

Maintain appropriate water chemistry — control total dissolved solids (TDS), pH, mineral content; perform regular blowdown; use biocides or treatment chemicals to prevent fouling, scale and corrosion.

Inspect structural components, basins, gaskets, seals — repair corrosion, leaks, cracks promptly.

Monitor actual water levels in the sump, makeup water flow, drift and blowdown losses — use float sensors, overflow alarms, water-use tracking.

During load changes (e.g. when only one of multiple towers is running), ensure that water distribution is balanced or isolate unused towers to prevent improper flow and overflow.

Avoid overcompensating water loss — don’t simply add more makeup water if the cause of water loss isn’t properly diagnosed.

As a manufacturer or supplier of water cooling towers, a company such as machcooling.com must pay attention to overflow causes during design, manufacturing, and after-sales support. Here’s how:

Design responsibility: Ensuring that towers (especially multi-cell/multi-tower systems) are supplied with proper piping, balanced flow, effective overflow drains and float controls.

Material and build quality: Using corrosion-resistant materials, designing basins and collection trays robustly to avoid leaks or cracking; ensuring spray nozzles and fill media are easy to maintain and clean.

Guidelines and documentation: Providing customers with clear instructions for maintenance, water treatment, chemical dosing, blowdown cycles — to prevent fouling or scaling that might reduce evaporation capacity and lead to overflow problems.

Service support: Offering inspection, maintenance, and water-treatment services or recommendations — since many overflow causes result from neglect or improper treatment rather than manufacturing defects.

Overflow in a water cooling tower or water cooled tower is not usually a simple failure — it is often a symptom of deeper issues in design, hydraulic balance, water chemistry, maintenance, or operation. By understanding the common causes — including piping imbalance, malfunctioning makeup valves, clogging, fouling, structural leaks, or mismanaged water addition — operators can take preventive measures.

Manufacturers like machcooling.com have a critical role: to design systems with proper safeguards, supply robust hardware, and help clients implement good operational and maintenance practices. When done right, a well-designed and well-maintained water cooling tower system can operate efficiently for years — without overflow, water waste, or unexpected downtime.