We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-29 Origin: Site

Cooling towers are the backbone of industrial and HVAC systems, keeping water at the right temperature so plants run efficiently. But did you know that what enters a cooling tower is just as important as how it cools? That’s where intake filters come in. Without proper filtration, debris, dust, and other contaminants can damage your system, reduce efficiency, and increase maintenance costs. Let’s explore what makes an intake filter the best choice for your cooling tower.

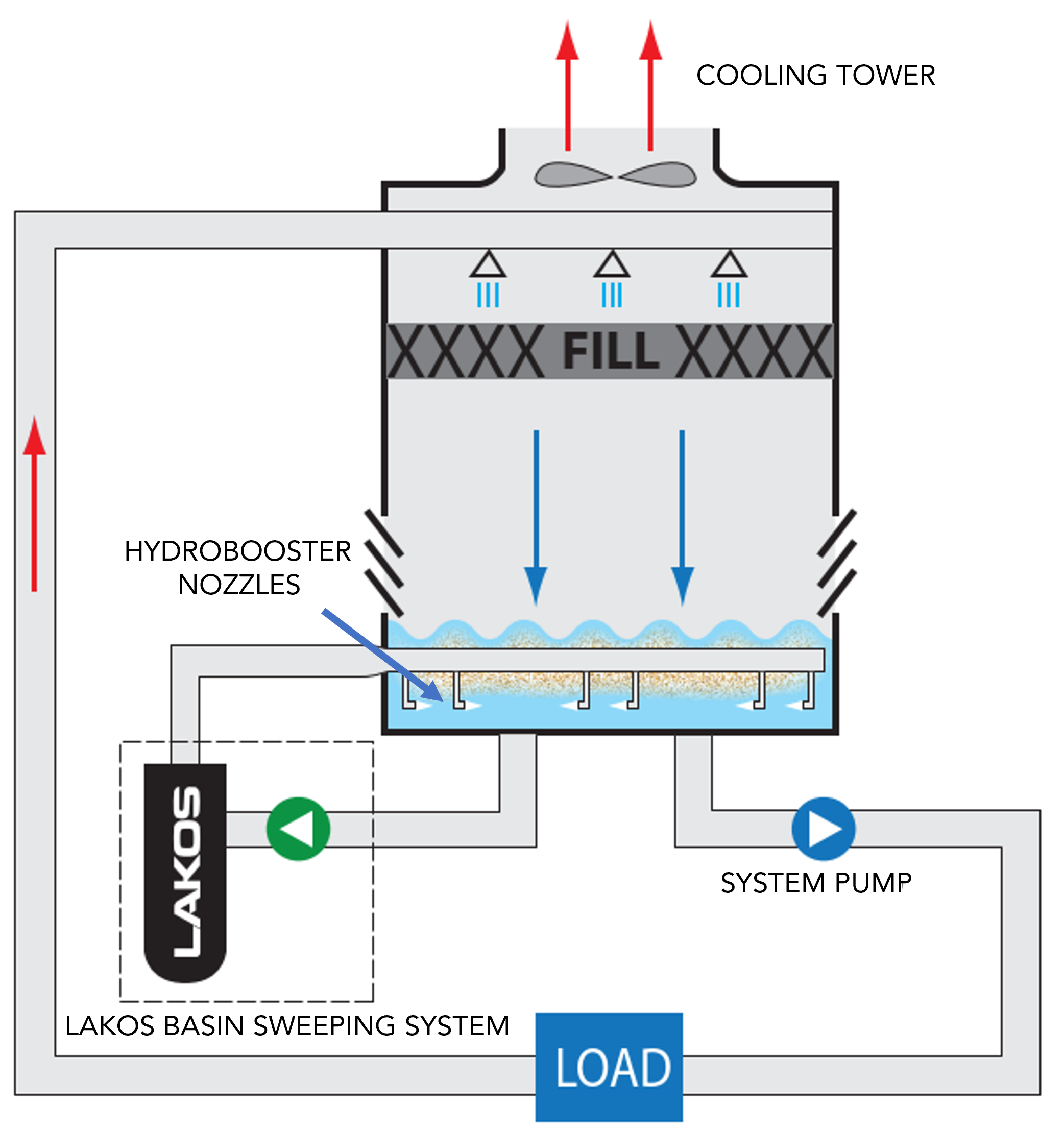

Cooling towers may look simple, but they deal with thousands of gallons of water daily. Any debris entering the system can clog nozzles, damage pumps, and contaminate water, leading to costly downtime. Installing a high-quality intake filter is the first line of defense, ensuring your cooling tower operates efficiently and reliably.

An intake filter is a device installed at the water or air entry points of a cooling tower. Its main function is to trap debris, dust, leaves, and other particles, preventing them from entering the system and causing fouling or mechanical wear.

By keeping water and airflow clean, intake filters prevent:

Clogging of pumps and pipes

Reduced heat transfer efficiency

Excessive scaling and fouling

Biological growth like algae and bacteria

This translates to lower maintenance, longer equipment life, and better performance.

Intake filters act as the first barrier against leaves, sand, algae, and industrial dust, protecting the water basin and airflow systems.

Clean water ensures consistent heat transfer, reduces chemical treatment needs, and maintains optimal tower operation.

By protecting pumps, fans, nozzles, and fill media from debris, filters help your cooling tower last longer and operate more reliably.

Simple, cost-effective filters that trap large particles before entering the tower. Easy to install but require regular cleaning.

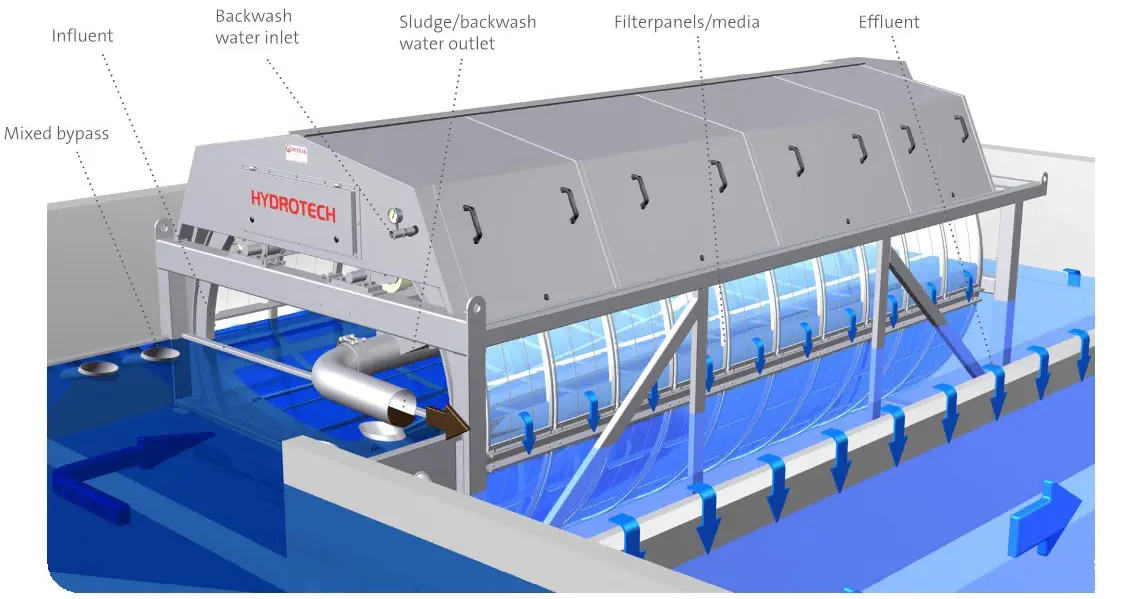

Rotating drum filters offer continuous filtration and are ideal for large industrial systems, reducing manual maintenance.

Made of sturdy bars, these trap larger debris. Often used as the first stage in multi-stage filtration systems.

For high-purity applications, fine media filters remove smaller particles and biological contaminants, improving water quality dramatically.

Stainless steel: Durable, corrosion-resistant, long-lasting

Plastic/Composite: Lightweight, corrosion-proof, cost-effective for smaller systems

Filters exposed to sunlight and water must resist UV degradation and corrosion to maintain performance over time.

Choose a mesh size appropriate for the expected debris. Too fine can clog frequently; too coarse may allow contaminants through.

Ensure the filter handles the tower’s water flow without excessive pressure drop, which can reduce pump efficiency.

Filters that are self-cleaning or easily removable reduce downtime and labor costs.

Ideal for moderate debris levels, offering consistent filtration with minimal maintenance.

Perfect for large industrial cooling towers, continuously removing debris without manual intervention.

Robust filters with automated cleaning, ideal for heavy debris or outdoor exposure.

Install filters upstream of the water basin or air intake

Ensure proper sealing to prevent bypass of unfiltered water

Match filter size to flow requirements for best efficiency

Regular inspection and cleaning

Replace worn media on schedule

Check automated systems for proper function

Proper maintenance keeps the system running efficiently and prolongs the life of both the filter and the tower.

Using undersized filters

Skipping cleaning schedules

Installing filters in improper locations

These mistakes can reduce efficiency and increase maintenance costs.

Clean water and airflow reduce fouling in fill media and pumps, leading to:

Improved heat transfer

Lower energy consumption

Extended equipment lifespan

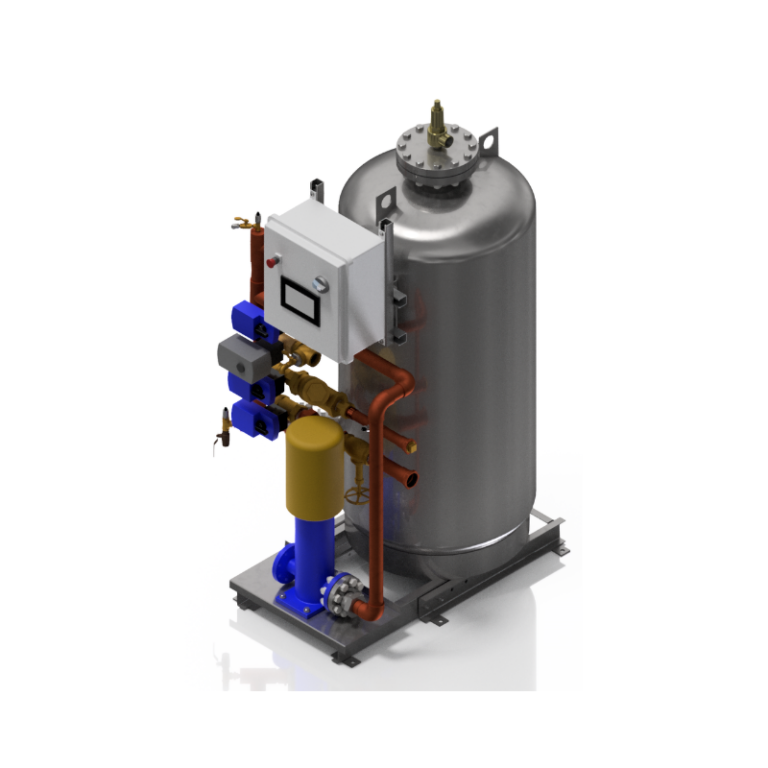

Mach Cooling (https://www.machcooling.com/) produces durable, high-efficiency intake filters designed for industrial, HVAC, and power plant applications. Their filters are engineered for:

Optimal debris removal

Minimal pressure drop

Long-term corrosion and UV resistance

Choosing a trusted manufacturer ensures reliability, performance, and peace of mind.

Industrial plants using Mach Cooling filters report:

Reduced pump maintenance

Fewer system shutdowns

Improved thermal performance

These benefits translate to lower operational costs and higher efficiency.

Smart sensors and automated cleaning

Multi-stage hybrid filtration systems

Advanced materials for durability and UV protection

These innovations aim to make cooling towers more efficient, sustainable, and low-maintenance.

Selecting the best cooling tower intake filter is more than just trapping debris—it’s about protecting your system, optimizing performance, and reducing operational costs. High-quality filters from trusted manufacturers like Mach Cooling ensure your cooling tower operates efficiently, reliably, and sustainably for years to come.