We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-12-20 Origin: Site

Efficient cooling tower operation isn’t just about getting the cold water you need — it’s about saving water, reducing energy costs, extending equipment life, and improving overall industrial performance. This is especially true for applications involving industrial water cooling towers, cooling tower water system design, and enhanced operational strategies like enhanced efficiency in cooling tower water distribution. Working with experienced water cooling tower manufacturers such as Mach Cooling (https://www.machcooling.com/) can help facilities achieve these benefits through optimized design and engineering.

In this article, we’ll explore why cooling water tower efficiency matters, what advantages it offers, and how you can measure and maximize these benefits in your facility.

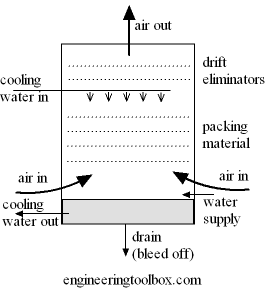

Cooling tower efficiency refers to how well a cooling tower rejects heat relative to the theoretical maximum it could achieve under given ambient conditions. Higher efficiency means the system cools water closer to the ambient wet-bulb temperature using the least amount of water and energy.

An efficient system includes:

Effective water distribution to all fill media

Optimized airflow and evaporation

Minimal drift and blowdown

Low energy consumption

Good cooling tower water savings performance

Improving efficiency reduces losses and maximizes output from each gallon of water and kilowatt of energy used.

Efficient cooling towers deliver measurable advantages across cost, water use, performance, and sustainability.

One of the primary benefits of higher efficiency is conserving water. With optimized operation, a cooling tower can operate at higher cycles of concentration, meaning each unit of water is reused more times before needing replacement or blowdown.

Water Savings Breakdown

| Efficiency Improvement | Estimated Water Savings |

|---|---|

| Increase cycles of concentration | 20–50% less makeup water required (POWER Magazine) |

| High-efficiency drift eliminators | 10–20% less water lost to drift (ICSThailand) |

| Advanced controls/automation | Significant targeted savings (The Department of Energy's Energy.gov) |

These water savings not only cut utility bills but also support environmental stewardship in water-scarce regions.

Efficient towers reduce energy use by:

Decreasing fan and pump loads

Enhancing heat transfer so chillers and condensers don’t work as hard

Reducing load on supporting HVAC equipment

As energy use drops, operating costs fall. Improved energy efficiency can also contribute to lower greenhouse gas emissions and support sustainability goals.

Efficient cooling towers run cooler and cleaner, which brings:

Reduced risk of scale, corrosion, and fouling

Lower maintenance frequency

More consistent water temperature for process and HVAC systems

This translates into fewer unplanned shutdowns and longer life for pumps, heat exchangers, and other connected equipment.

With better water management:

Makeup water costs go down

Chemical treatment needs decline

Blowdown water discharge is reduced

Lower chemical and water costs improve overall cooling tower water system economy and free budget for other plants or capital projects.

Efficient cooling towers improve sustainability by:

Reducing overall water withdrawal and wastewater discharge

Lowering energy-related carbon emissions

Helping facilities meet regulatory standards for water use

For industrial operations, this supports corporate environmental goals and may ease compliance with local and national regulations.

Efficient cooling towers influence both thermal performance and water conservation, which are interconnected.

Poor water distribution leads to dry spots on the fill and inefficient cooling. Modern designs and control systems ensure:

Even distribution of water across the fill media

Maximum contact between water and airflow

Better heat transfer and evaporation

This not only improves cooling but also water cooling tower efficiency by reducing unnecessary water losses.

Incorporating automated conductivity monitors, blowdown control systems, and real-time analytics helps maintain optimal operation, adjusting parameters like blowdown and chemical feed in response to actual conditions — helping save both cooling tower water and energy.

Industrial processes often demand large-scale cooling, making efficiency improvements even more impactful.

Efficient towers help maintain consistent water temperatures, critical for processes such as metal fabrication, chemical production, or power generation. Stable cooling contributes to higher product quality and fewer interruptions. (AADTech)

When a cooling tower operates efficiently, chillers work less to achieve the same thermal results. Lower chiller load means:

Reduced energy usage

Slower wear on compressors

Longer equipment lifespans

This synergy between cooling tower and chiller systems boosts overall plant efficiency.

Efficient cooling towers can be adapted to changing operational needs, enabling facilities to scale process cooling without excessive redesign or equipment replacement.

Selecting the right industrial water cooling tower partner makes a significant difference in achieving efficiency goals.

Mach Cooling (https://www.machcooling.com/) is a trusted provider of high-performance cooling towers that combine robust engineering with efficient design. Their solutions include:

Customized systems for industrial process cooling

Enhanced water distribution technologies

Designs optimized for cooling tower water savings and performance

With expert engineering support, Mach Cooling helps facilities align their cooling infrastructure with efficiency, sustainability, and cost targets.

To quantify cooling tower efficiency, facilities often track:

| Metric | What It Measures |

|---|---|

| Makeup Water Use | Fresh water required per unit heat rejected |

| Blowdown Volume | Water discharged to control dissolved solids |

| Cycles of Concentration | How many times water is reused before blowdown |

| Drift Losses | Water lost as droplets from the tower |

Monitoring these metrics helps identify inefficiencies and opportunities for improvement.

Energy per ton of cooling

Cooling water temperature differential (ΔT)

Overall plant energy use related to cooling loads

Tracking these values ensures that improvements in cooling tower efficiency translate into real cost and performance benefits.

To recap, improved cooling water tower efficiency provides:

Significant cooling tower water savings and reduced utility bills

Lower energy and operating costs

Increased equipment life and reliability

Enhanced environmental sustainability

Better process temperature control

Greater operational flexibility

Investing in efficient cooling tower design and working with experienced water cooling tower manufacturers like Mach Cooling supports both economic and environmental objectives — delivering measurable returns over time.