We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-13 Origin: Site

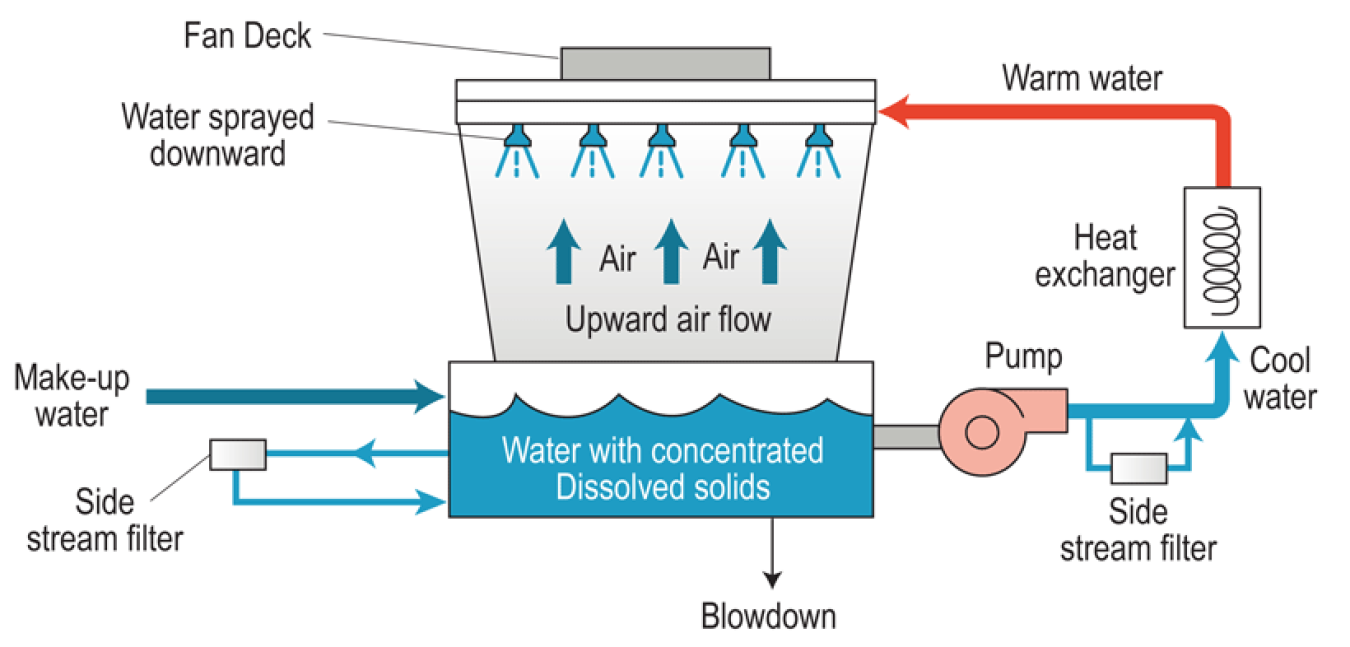

Cooling towers work quietly in the background, yet they carry an enormous responsibility: removing heat from industrial processes, power generation systems, and HVAC applications. While fans, fill, and drift eliminators often steal the spotlight, water quality is the invisible force that determines how well a cooling tower performs over time.

This is where filtration becomes critical. Among the many filtration strategies available today, side stream filtration and full flow filtration stand out as the two most widely discussed approaches. Understanding how they differ—and when to use each—can make the difference between a stable, efficient cooling system and one plagued by fouling, corrosion, and rising operating costs.

Think of a cooling tower as a living system. Water constantly absorbs airborne dust, sand, corrosion byproducts, organic matter, and biological contaminants. Without filtration, these solids circulate endlessly, settling on fill surfaces and heat exchangers like plaque in arteries.

Effective filtration helps:

Reduce fouling and scaling

Improve heat transfer efficiency

Lower chemical consumption

Extend equipment lifespan

In short, filtration keeps the system breathing freely.

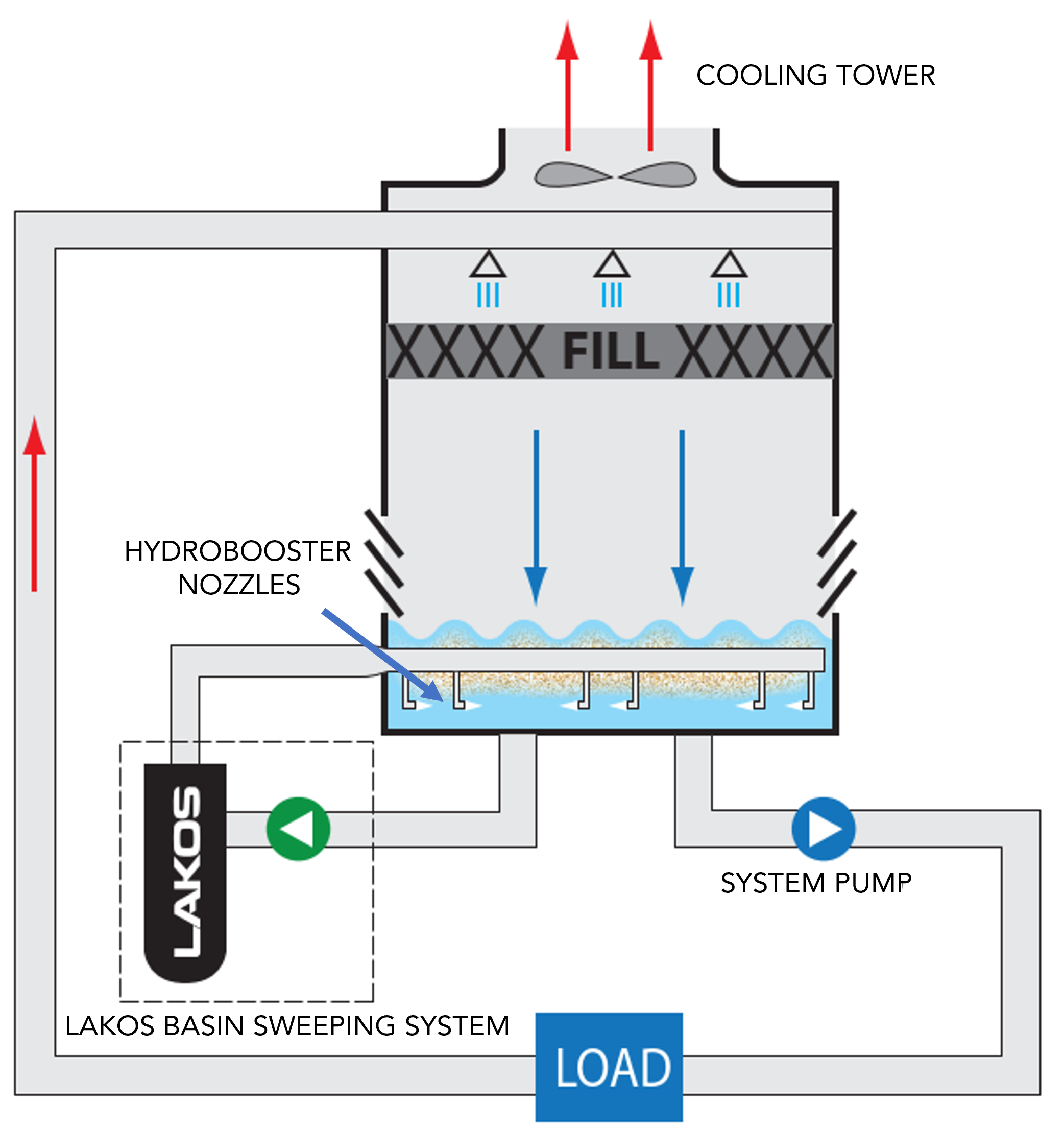

Side stream filtration is a smart, continuous cleaning approach. Instead of filtering all circulating water at once, a small portion of the total flow is diverted through a dedicated filter and then returned to the system.

Typically, 5–15% of the circulating water passes through a side stream filter at any given time. Over hours and days, this continuous “polishing” effect gradually removes suspended solids from the entire cooling tower loop. It’s like tidying your house a little every day instead of doing a massive cleanup once a year.

Most side stream systems operate efficiently within a controlled flow window, ensuring effective solids removal without excessive pressure drop or energy use.

Full flow filtration takes a more aggressive approach. As the name suggests, 100% of the circulating water passes through the filtration system before returning to the cooling tower.

These systems are installed directly in the main circulation line and must handle extremely high flow rates. Filters are designed for low resistance, but they still require powerful pumps and robust construction.

Because all water flows through the filter, full flow systems often demand:

Larger filter housings

Stronger structural support

More complex piping layouts

This makes them effective—but also more demanding.

Side stream filtration cleans water progressively over time. Full flow filtration cleans everything instantly. One relies on patience and consistency; the other relies on brute force.

Side stream filtration excels at removing fine suspended solids that accumulate gradually. Full flow filtration is better suited for systems where immediate particle removal is critical.

Side stream systems are modular, compact, and easy to retrofit. Full flow filtration often requires system downtime and extensive engineering work.

Suspended solids act as anchors for scale formation and biofilm growth. By continuously removing these particles, side stream filtration dramatically reduces fouling potential.

Cleaner water means cleaner heat transfer surfaces. Over time, even a thin layer of fouling can reduce thermal efficiency significantly. Filtration helps keep performance where it should be—at peak levels.

Side stream filtration systems typically require lower upfront investment compared to full flow systems, especially in large-capacity cooling towers.

With lower energy consumption and simpler maintenance, side stream filtration often delivers a faster and more predictable return on investment.

Manufacturing plants, petrochemical facilities, and refineries favor side stream filtration for its reliability, flexibility, and cost-effectiveness.

In commercial buildings and data centers, side stream filtration provides consistent water quality without disrupting daily operations.

Full flow filtration is best suited for niche applications—systems with extremely high contamination risk or processes that cannot tolerate any particulate presence, even momentarily.

Filtration and chemical treatment work best as a team. By removing suspended solids, filtration allows chemicals to focus on controlling corrosion, scale, and biological growth—rather than being wasted on dirt.

The right choice depends on system size, contamination load, operating conditions, and budget. In many real-world applications, side stream filtration offers the best balance of performance, simplicity, and cost control.

A common misconception is that filtering more water automatically means better results. In reality, consistent filtration often outperforms excessive filtration, especially when energy and maintenance costs are considered.

A well-designed filtration system isn’t just about filters—it’s about understanding water chemistry, hydraulics, and real operating conditions. This is where experienced manufacturers make a real difference.

Mach Cooling (https://www.machcooling.com/) provides professionally engineered cooling tower solutions, including side stream filtration systems designed for durability, efficiency, and easy integration. Their expertise ensures reliable performance across industrial, commercial, and power applications.

The future points toward smarter filtration: automated backwashing, real-time monitoring, and tighter integration with digital water management systems.

When comparing side stream filtration vs full flow filtration, there is no one-size-fits-all answer. However, for most cooling tower systems, side stream filtration delivers the optimal combination of efficiency, cost-effectiveness, and operational simplicity. By keeping circulating water clean and stable, it quietly protects the entire cooling system—just like a steady heartbeat keeps the body alive.