We Provide Cooling Tower Solution

English

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-04 Origin: Site

Cooling towers are the unsung heroes of industrial plants, HVAC systems, power stations, and data centers. They quietly remove heat, keep processes stable, and help equipment operate efficiently. But here’s the truth many operators learn the hard way: a dirty cooling tower can undermine the entire system.

That’s why cooling tower cleaning isn’t optional—it’s essential.

In this complete guide, we’ll break down what cooling tower cleaning is, why it matters, how it’s done, how often it should happen, and why choosing the right cooling tower manufacturer—such as MACH Cooling—makes long-term maintenance much easier.

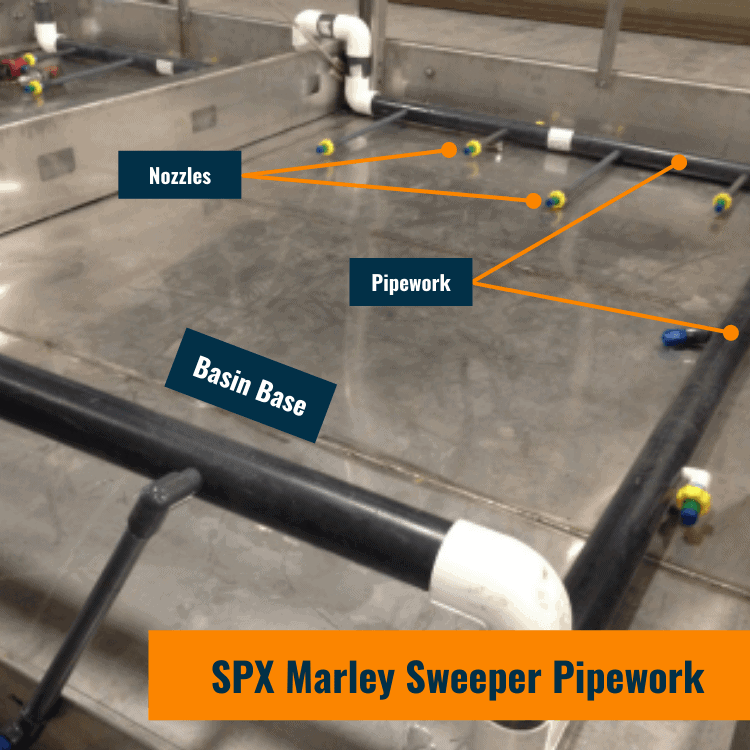

Cooling tower cleaning is the process of removing scale, sludge, algae, bacteria, and debris from all key components of a cooling tower system. This includes the basin, fill media, spray nozzles, drift eliminators, piping, and heat exchange surfaces.

Think of it like cleaning the arteries of your cooling system. When they’re clear, everything flows smoothly. When they’re clogged, efficiency drops and risks rise.

Skipping or delaying cooling tower cleaning may save time today—but it almost always costs more tomorrow.

Scale and fouling act like insulation. Even a thin layer of mineral scale can reduce heat transfer efficiency by 5–15%, forcing pumps and fans to work harder and consume more energy.

Warm, stagnant water is a perfect breeding ground for bacteria, including Legionella. Without proper cleaning and disinfection, contaminated droplets can become airborne, posing serious health risks and legal liabilities.

Cooling towers operate in open, harsh environments. Contamination is inevitable.

As water evaporates, dissolved minerals such as calcium and magnesium are left behind, forming hard scale on heat transfer surfaces.

Algae, slime, and bacteria thrive in warm, wet conditions—especially when nutrients and sunlight are present.

Dust, leaves, insects, and airborne particles enter through air inlets and settle in the basin and fill.

Different situations require different cleaning approaches.

This involves physical removal of debris using brushes, vacuums, and high-pressure water. It’s effective for sludge and visible contamination.

Chemical descalers dissolve mineral deposits, while biocides eliminate bacteria and algae. This method reaches areas manual cleaning cannot.

Online cleaning allows limited cleaning while the system is running

Offline cleaning requires shutdown but delivers the most thorough results

A professional cooling tower cleaning follows a structured, safety-first approach.

Lockout/tagout procedures, personal protective equipment, and chemical handling plans are essential before any work begins.

Drain the basin

Remove sludge and debris

Clean fill media, spray nozzles, strainers, and drift eliminators

Descaling chemicals remove mineral buildup, followed by biocide treatment to disinfect the system and prevent regrowth.

Because they are directly exposed to air, open cooling towers accumulate dirt and biological growth faster and require more frequent cleaning.

Closed systems stay cleaner overall, but internal coil fouling still demands scheduled inspection and cleaning.

Manufacturers like MACH Cooling design cooling towers with maintenance-friendly layouts, making cleaning faster, safer, and more effective.

There’s no universal schedule, but general recommendations include:

Light industrial or comfort HVAC systems: every 6 months

Heavy industrial applications: quarterly

High-risk or critical facilities: frequent inspections with scheduled cleaning

Water quality, operating load, and environment all play a role.

Even well-intentioned maintenance can fall short due to common errors:

Using incorrect or incompatible chemicals

Ignoring fill media and hidden surfaces

Skipping final disinfection

Poor documentation and follow-up

These mistakes often lead to recurring problems and higher long-term costs.

Consistent cooling tower cleaning delivers real, measurable advantages:

Lower energy consumption

Improved heat transfer efficiency

Reduced water and chemical usage

Extended equipment lifespan

Improved system reliability

Cooling tower cleaning should align with:

ASHRAE and industry guidelines

Local health and safety regulations

Water treatment best practices

Proper documentation is critical—not just for compliance, but for long-term system optimization.

While basic cleaning can be handled in-house, professional solutions combine engineering design, service expertise, and long-term planning.

MACH Cooling provides:

Cooling towers designed for easy access and cleaning

Durable materials that resist corrosion and scaling

Integrated solutions that simplify maintenance and operation

Their focus on cleanability and reliability helps operators reduce downtime and total lifecycle costs.

Cooling tower cleaning isn’t just routine maintenance—it’s a strategic investment in efficiency, safety, and system longevity. A clean cooling tower runs cooler, lasts longer, and costs less to operate.

And when your cooling system is built by a manufacturer that understands maintenance from day one—like MACH Cooling—keeping it clean becomes easier, smarter, and more sustainable.